Gujarat’s textile connection is deeper than geography. The state not only hosts India’s strongest fabric and garment clusters, but it also leads the production of high-purity industrial salt. As a result, textile dyeing houses benefit from salt that is chemically balanced, moisture-controlled and delivered at the scale required for continuous production.

Why Salt Is Critical in Dyeing and Printing Processes

Dyeing is more than submerging fabric in coloured water — it requires chemistry to ensure colour binds to fibres. Salt plays a critical role in this process.

Salt supports efficient dyeing by:

Accelerating dye exhaustion into fibres

Balancing ionic charge in dye baths

Reducing colour residue during washing

Enhancing colour uniformity

Minimising shade variations across production runs

When salt purity drops, issues like uneven dyeing, fuzzy shades, high rewash rates and fabric blotching increase. That’s why mills and dyeing houses need salt they can rely on consistently, and why most procure directly from a textile Salt Manufacturer in Gujarat.

Why Gujarat Leads the Industrial Textile Salt Market

Several advantages make Gujarat the preferred sourcing hub for textile processors:

✔ Access to natural salt pans and coastal belts

The state produces the majority of India’s industrial-grade salt thanks to its ideal climate and coastal landscape.

✔ Modern refinement and grading systems

Top suppliers use washing, drying and screening enhancements to produce salt with low impurities — exactly what textile plants require.

✔ Consistency across batches

Leading manufacturers supply uniform granular distribution and repeatable chemical composition — reducing process variability inside dye houses.

✔ Bulk production and logistics

Factories can order 25 kg sacks, jumbo bags or full truckloads for uninterrupted operations — key for large-volume units.

This reliability is why India’s major garment clusters — Tiruppur, Ludhiana, Surat, Ahmedabad and Bengaluru — partner with textile Salt Supplier from Gujarat networks.

How Purity Influences Colour Absorption and Dye Efficiency

The chemical structure of salt determines how effectively dye sticks to fibres. Optimal textile-grade salt includes:

High sodium chloride (NaCl) concentration

Very low sulphates and calcium/magnesium

Low moisture content

Even particle size

When textile salt quality is poor, dyeing baths require more chemicals to compensate — increasing cost and wastewater load.

With high-purity salt from a reliable textile Salt Manufacturer in India, processors experience:

Benefit | Production Advantage |

Enhanced dye uptake | Lower dye consumption |

Reduced colour bleeding | Fewer defective lots |

Better shade reproducibility | Reliable repeat orders |

Lower TDS in effluent | Cheaper wastewater treatment |

For high-efficiency processing and sustainability goals, salt purity matters as much as machine quality.

Choosing the Right Grade of Textile Salt: What Dyeing Houses Should Check

Not all salt bags labelled “industrial salt” are designed for textile use. Mills should evaluate suppliers using the checklist below:

1️⃣ Chemical specifications

Confirm NaCl purity, Ca/Mg percentage and moisture levels match process requirements.

2️⃣ Granule uniformity

Avoid coarse, oversized or mixed-grade salt that dissolves slowly and unevenly.

3️⃣ Moisture-controlled packaging

High humidity exposure causes clumping and uneven brine formation.

4️⃣ Available supply formats

Textile operations run continuously — manufacturers must provide timely replenishment options.

5️⃣ Technical assistance

A quality textile Salt Supplier from Gujarat advises mills on grade recommendations for cotton, viscose, denim and polyester.

Checking these details helps dye houses avoid production slowdowns and improve shade consistency.

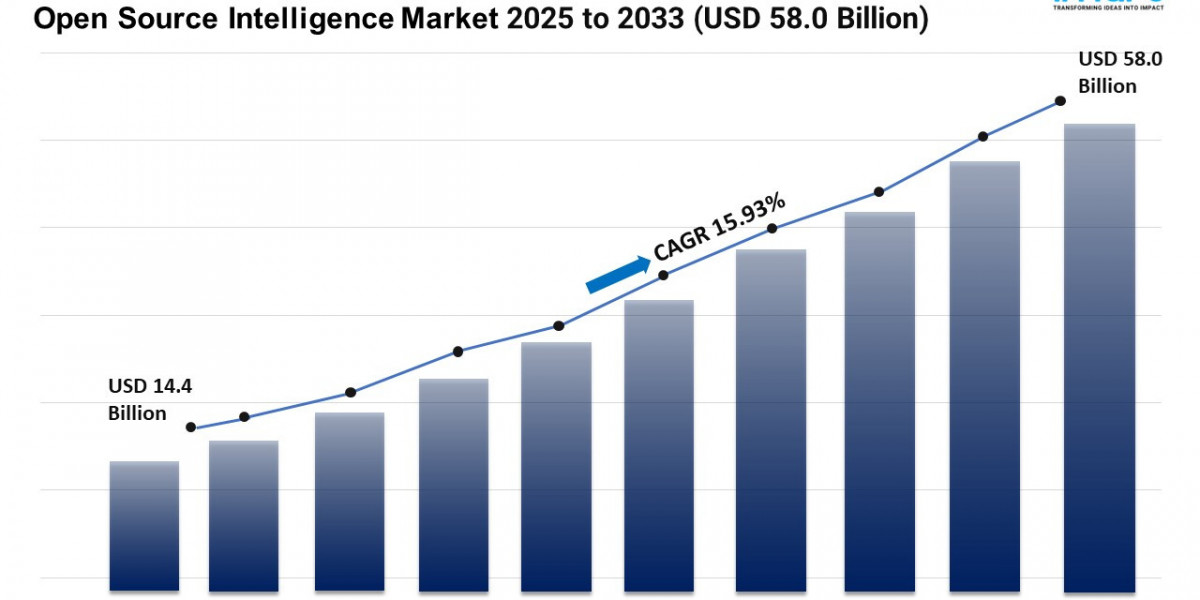

Future Trends: Why Demand for Textile Salt Will Continue Rising

Several structural shifts in the industry are driving long-term demand for high-performance textile salt:

Fashion brands demand tighter shade tolerances

Denim manufacturing has increased brine usage

Zero-liquid-discharge dyeing plants require predictable salt composition

Global buyers expect sustainability with lower wastewater output

Premium clothing exports demand longer-lasting colour vibrancy

These requirements drive mills toward dependable salt that simplifies process control rather than complicates it — reinforcing Gujarat’s status as the country’s top textile Salt Manufacturer in Gujarat.

Why Partnering With the Right Supplier Protects Profitability

Buying based only on price might look attractive, but it usually increases total production cost due to dye loss and reprocessing. The most profitable textile operations rely on suppliers that deliver

Consistent production volume

Quality certifications

Transparent laboratory test reports

Reliable logistics and lead times

A strong supply partnership reduces operational risk while improving product quality — a win for textile plants and fashion brands worldwide.

Final Thoughts

Salt may seem like a low-value input, but in textile manufacturing it is one of the most influential raw materials. Without reliable salt quality, dyeing efficiency drops and profitability suffers. That is why mills across India and abroad continue to partner with Gujarat — home to the most trusted textile Salt Manufacturer in India and the world’s strongest network of textile Salt Supplier from Gujarat.

With consistent purity, granule uniformity and bulk readiness, Gujarat remains the backbone of India’s textile salt supply and a vital link in the global garment industry.