Transformers for electrical power are an essential component for modern power systems. They are responsible for ensuring the secure and reliable transfer of power across various voltages. The manufacturing as well as maintenance of transformers should be carried out in complete conformity to the standards of industry to guarantee safety, effectiveness and reliability. Electrical transformer suppliers play a critical role in this ecosystem, and compliance with regulatory and technical standards is non-negotiable. Knowing these guidelines is vital not just for manufacturers but also companies that depend on transformers to ensure uninterrupted supply of power.

Importance of Compliance for Electrical Transformer Suppliers

Compliance with law isn't only legally required but is also a control procedure. Manufacturers of electrical transformers must follow recognized standards in order to shield end users from risks from fire in addition to electrical malfunctions. Infractions to the law could create disastrous outcomes, including disruptions to electricity supply, destruction of equipment and devices, as well as dangers to workers. In addition, businesses who adhere to international standards increase their credibility as well as improve international trade and the quality of their power systems in line with international requirements. If you're operating in the distribution of transformers across all of the United Kingdom, ensuring conformity is vital to ensure that you are in compliance with the standards of national and industry regulations.

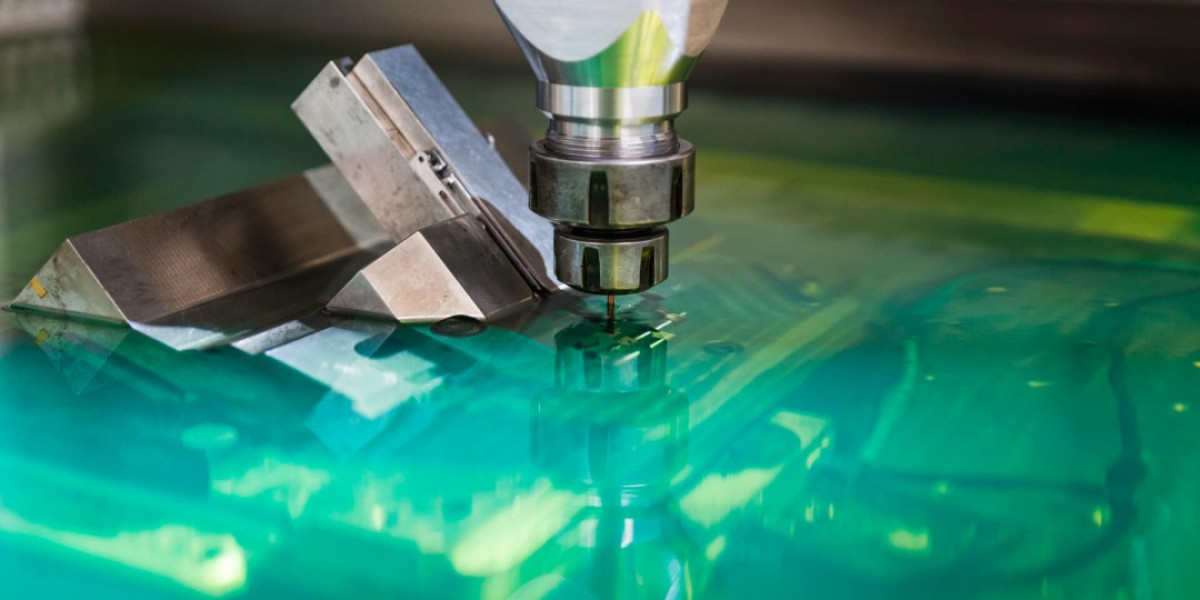

Key Standards for Transformer Design and Manufacturing

One of the largest aspects of compliance is the creation and manufacture of transformers. Manufacturers of transformers for electrical use must be certain that their products meet the specifications laid out in the standard specifications like IEC 60076. This standard establishes the essential standards for transformers powering. They must meet requirements such as the degree of insulation as well as the voltage ratios, short circuit resistance capability and the temperature increase limit. The compliance with these standards ensures that transformers work effectively under various loading conditions and will endure mechanical and electrical stress without failing. If you're an entrepreneur operating in the UK following British standard BS EN60076 is vital since it conforms to international standards, and also addresses local requirements regarding protection of the environment and safety.

Safety and Environmental Regulations

Security is one of the most important aspects when it comes to the production of transformers. Electrical transformer makers should ensure they have constructed their transformers in a way to protect against electrical shocks, overheating along with other risks. This means strict tests of the insulation systems in the same way as protection relays, as well as grounding systems. In addition, environmental regulations are starting to influence transformer design. The manufacturers must limit the pollution, reduce leakage and make use of environmentally friendly components when they can be found. Compliance with directives such as the restriction of harmful substances (RoHS) and waste Electrical as well as Electronic Equipment (WEEE) guarantees that transformers are compliant with current requirements for environment protection and protect human health.

Quality Control and Testing Procedures

In order to ensure the consistency of the quality of the transformers produced is an essential requirement that demands quality control methods. The producers of transformers for electrical use must perform frequent tests throughout the production process, including types tests, standards tests and testing samples. Tests for type verify the transformer's design as well as its capability under extreme conditions. Routine tests make sure that the machines comply with operating specifications. Electrical transformer makers in the UK generally follow the standards that are set out by various organisations like those of British Standards Institution (BSI) along with the Institute of Electrical and Electronics Engineers (IEEE). These guidelines guarantee that each transformer which leaves the factory has been tested to ensure that it is compatible with the requirements for performance and reduces the chance that field failures could occur.

Documentation and Traceability

Documentation is another essential aspect of conformity. Electrical transformers need to keep detailed documentation of their design calculations along with material certifications and test results as well as instructions on how to install. They allow regulators to make sure that the transformer is in compliance with established standards and aids to identify issues when there are issues. It is crucial to trace the transformer's origins. Traceability is especially important in transformer supply UK wide, where authorities may require proof of compliance with specific safety and environmental regulations. An accurate documentation will help support warranty claims along with customer service, and continual improvements in the manufacturing process.

International Standards and Certification

For businesses operating on the international market, international certifications are increasingly important. Standards like ISO 9001 for quality management and ISO 14001 for environmental management provide proof of compliance with high-quality standards. Additionally, many manufacturers require certification from independent laboratories to allow the verification that they are in compliance with the specifications of their technical suppliers. These certifications also increase the credibility of companies that sell transformers that are electrical and offer assurance to clients regardless whether they are in the market within the nation or abroad. In the UK the conformity with international standards guarantees that transformers can be connected to the grids of the country and they're in line with the local standards of utility companies.

Conclusion

Electrical transformers' suppliers must be responsible for making sure that they are safe, effective and reliable in their energy systems. Compliance with standards of safety, technology and environmental requirements is essential to ensure high-quality transformers that are up to date with the requirements of energy. From design and manufacturing to testing, documenting and certification, every element of the production of transformers has to comply with the laws in force. For firms operating in the UK, being in compliance with standard international and national requirements is essential to ensure that they are in full compliance with laws and also the confidence of consumers. The end result is that the standardization process safeguards not just the customers but also the infrastructure, which is dependent upon a reliable supply of electricity.

Frequently Asked Questions

What are the most important specifications that electric transformer makers have to follow?

The most important standards are IEC 60076 for the development of transformers BS EN 60076 for UK compliance, and ISO certifications that ensure the control of environmental quality as well as security. They guarantee security and safety in addition to conformity to regulations.

What's the importance of ensuring compliance with the distribution of transformers within the UK?

Conformity guarantees that transformers operate without danger as long as they meet environmental regulations and stay clear of electrical hazards. Also, it increases trust between customers and regulatory authorities.

What are ways the electrical transformer manufacturers ensure that their transformers are high-quality?

They utilize strict testing procedures that incorporate routine, type and sample testing. They record their processes in full detail. They perform tests, make inspections and follow methods of traceability to ensure that the same level of service is provided.

What impact can environmental regulations have in the production of transformers?

The Environmental Regulations require companies to cut down on hazardous substances, stop leaks from oil, and lower emissions levels. Compliance with directives such as RoHS and WEEE assures the sustainability of the manufacturing process for transformers.