Market Segmentation Overview

By Product

Mineral-based Fluids: Traditional oils derived from petroleum, offering cost-effective solutions but with environmental concerns.

Synthetic Fluids: Man-made formulations providing superior performance and longer tool life, suitable for high-precision applications.

Bio-based Fluids: Derived from renewable resources like vegetable oils, these fluids are gaining popularity due to their eco-friendly properties and compliance with stringent regulations.

Click here the Metalworking Fluids Market report to view the report

By Application

Neat Cutting Oils: Undiluted oils used for heavy-duty cutting operations, providing excellent lubrication.

Water Cutting Oils: Emulsions of oil and water, offering effective cooling and lubrication for various machining processes.

Soluble Cutting Oils: Water-based emulsions that provide cooling and lubrication, commonly used in general machining.

Semi-Synthetic Cutting Oils: A blend of synthetic and mineral oils, offering a balance between performance and cost.

Synthetic Cutting Oils: Fully synthetic formulations providing high performance and extended tool life.

Corrosion Preventive Oils: Used to protect metal surfaces from corrosion during storage and transportation.

Others: Specialized fluids catering to specific industrial needs.

By End Use

Machinery: Includes manufacturing equipment and tools requiring lubrication and cooling.

Transportation Equipment: Encompasses vehicles and components that undergo metalworking processes.

Metal Fabrication: Involves the creation of metal structures through cutting, bending, and assembling processes.

By Industrial End-Use

Construction: Utilization in machinery and equipment used in construction activities.

Electrical & Power: Application in the production of electrical components and power generation equipment.

Agriculture: Use in machinery and equipment for agricultural activities.

Automobile: Involvement in the manufacturing of automotive components and vehicles.

Aerospace: Application in the production of aircraft and aerospace components.

Rail: Utilization in the manufacturing of rail components and infrastructure.

Marine: Application in shipbuilding and marine equipment manufacturing.

Telecommunication: Use in the production of telecommunication equipment and infrastructure.

For more detailed segmentation : Metalworking Fluids Market

Latest Trends

1. Shift Towards Bio-based and Environmentally Friendly Formulations

There is a growing demand for bio-based and biodegradable metalworking fluids due to increasing environmental concerns and stringent regulations. These fluids, derived from renewable resources, offer reduced toxicity and improved safety profiles .

2. Integration of Smart Manufacturing Technologies

The adoption of Industry 4.0 technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), is influencing the development of intelligent metalworking fluids. These fluids are designed to interact with smart manufacturing systems, providing real-time monitoring and optimization .

3. Advancements in Fluid Technology

Innovations in fluid formulations, including the development of synthetic and semi-synthetic fluids, are enhancing the performance and environmental sustainability of metalworking processes. These advancements offer improved cooling efficiency, better lubrication properties, and enhanced corrosion protection .

Challenges

1. Strict Environmental Regulations

The metalworking fluids industry faces challenges in complying with stringent environmental regulations. Manufacturers are required to develop products that are eco-friendly, emit fewer pollutants, and degrade naturally, which necessitates significant investment in research and development .

2. Rising Raw Material Costs

Fluctuations in the prices of raw materials, such as base oils and additives, can impact the cost and availability of metalworking fluids. These fluctuations can affect market stability and profitability for manufacturers .

3. Worker Health and Safety Concerns

The use of traditional metalworking fluids, which may contain hazardous chemicals, poses health risks to workers. Ensuring the safety of workers requires the development and adoption of safer, non-toxic fluid formulations .

Opportunities

1. Product Innovation and Differentiation

Continuous product innovation is crucial for maintaining competitiveness in the metalworking fluids market. Manufacturers are focusing on developing high-performance formulations that provide superior lubrication and cooling properties, improved fluid life, and reduced environmental impact .

2. Expansion into Emerging Markets

The increasing industrialization in emerging economies presents significant growth opportunities for the metalworking fluids market. As industries in these regions expand, the demand for high-performance metalworking fluids is expected to rise .

3. Adoption of Closed-Loop Fluid Recycling Systems

Implementing closed-loop fluid recycling systems can enhance operational efficiency and ensure compliance with environmental norms. These systems reduce waste, lower disposal costs, and contribute to sustainability goals .

Key Players and Recent Developments (2025-2033)

Quaker Houghton .

FUCHS Group unveiled biodegradable, water-soluble lubricants targeting environmentally conscious industries in March 2025 .

Chevron Corporation announced a USD 100 million investment in R&D for advanced synthetic metalworking fluids in April 2025 .

Blaser Swisslube expanded into the Asia-Pacific region, strengthening its presence in high-growth industrial markets in May 2025 .

Conclusion

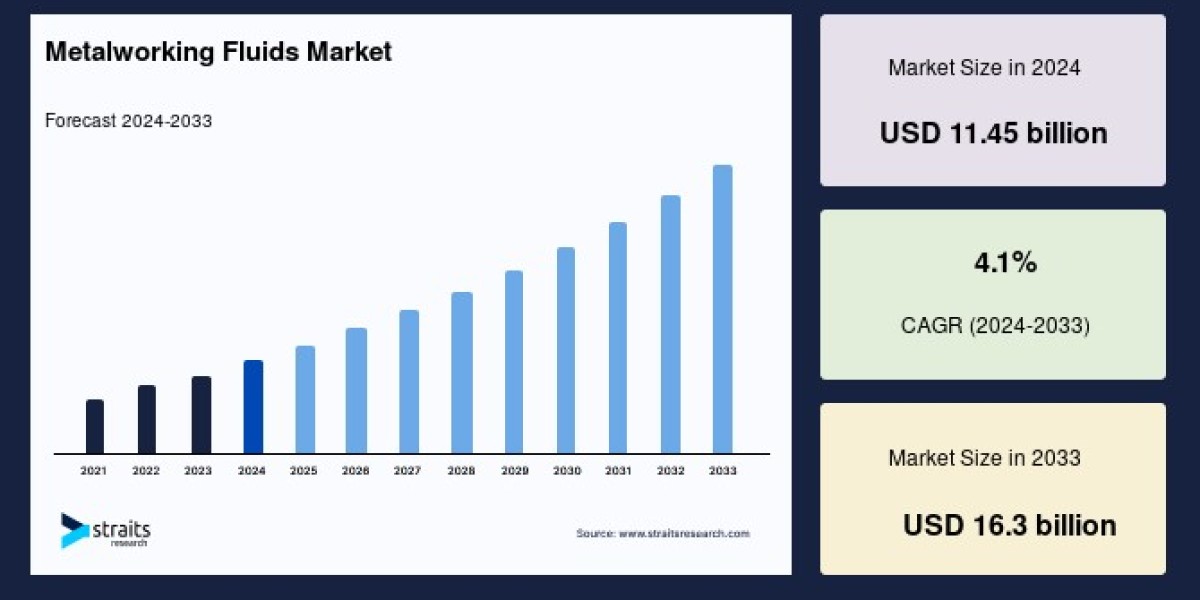

The metalworking fluids market is poised for significant growth, driven by technological advancements, environmental considerations, and evolving industrial needs. Manufacturers focusing on innovation, sustainability, and compliance with regulations will be well-positioned to capitalize on emerging opportunities. As industries continue to expand and modernize, the demand for high-performance metalworking fluids is expected to rise, presenting avenues for growth and development in the coming years.

For more detailed report, buy now