The way industries operate is changing fast. Not long ago, success in manufacturing was judged almost entirely by numbers—output, speed, and cost savings. But that picture is no longer complete. Businesses today are under constant pressure to prove that their growth is not coming at the expense of the planet or society. That’s where sustainability metrics step in, and industrial engineers are at the center of this shift.

By measuring the impact of production on the environment and communities, engineers are helping industries move beyond vague promises and into measurable progress. These metrics give companies a roadmap, showing not just how efficient they are, but how responsible their operations truly can be.

Why Measuring Sustainability Is Crucial

Customers are asking tougher questions, regulators are raising the bar, and investors want more than short-term profits. In this environment, it isn’t enough for a company to claim it cares about the environment—it must show proof. Numbers, when tracked properly, provide that proof.

Industrial engineers already have a reputation for squeezing waste out of systems and fine-tuning efficiency. Now, by embedding sustainability into the process, they extend that same skill to saving energy, cutting emissions, and protecting resources.

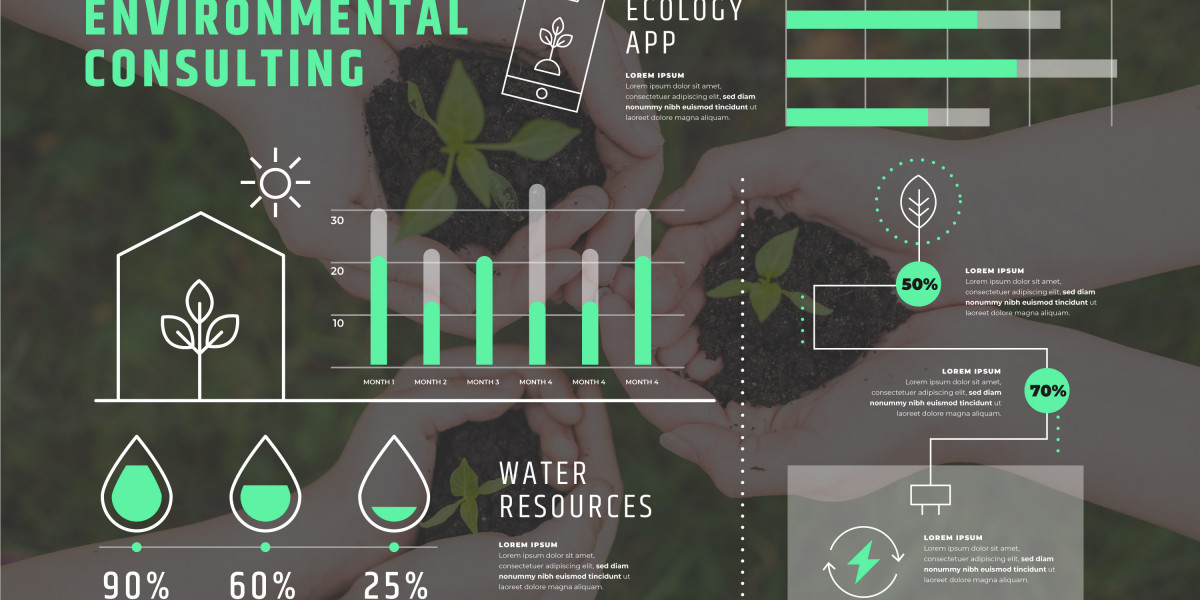

Common Metrics Used in Industry

Sustainability can feel broad, but engineers usually break it down into clear, measurable areas. Some of the most widely tracked include:

1. Energy Use

Instead of only calculating total consumption, engineers look at how much energy is required to make a single unit of product. This shines light on inefficiencies and creates space for adopting renewable sources or smarter machines.

2. Emissions

Carbon dioxide and other greenhouse gases remain the most pressing concern. Engineers use standardized frameworks to calculate emissions from direct operations, electricity use, and even supply chains. This paints a complete picture of a product’s footprint.

3. Water Dependence

Industries that rely on heavy water intake—like textiles or chemicals—track usage per product and how much water is recycled. These numbers drive conservation strategies that go beyond compliance.

4. Waste and Recycling

Rather than only focusing on disposal, engineers monitor how much waste is diverted from landfills and how much raw material is recovered. This shift supports the idea of a circular economy.

5. Workforce and Community Impact

Metrics aren’t just about resources. Hours of safety training, accident rates, and local community investments also help capture the broader social side of sustainability.

Turning Numbers Into Action

Collecting data alone isn’t the end goal. What sets industrial engineers apart is their ability to translate these measurements into change.

Process improvements: If a metric shows excessive energy use in one section of production, engineers can redesign layouts or adjust workflows to cut waste.

Smart tools: Advanced sensors, predictive maintenance, and digital monitoring systems allow energy and material use to be controlled more precisely.

Stronger supply chains: By working with vendors, engineers push for eco-friendly materials and better logistics.

Real-time updates: Continuous monitoring ensures that companies aren’t just reporting progress once a year but adjusting constantly.

Barriers Along the Way

Of course, measuring and improving sustainability isn’t always straightforward. Data often comes from multiple departments or global facilities, making it tough to maintain consistency. Companies also worry about balancing environmental goals with financial performance.

Another challenge is transparency. There’s a fine line between meaningful reporting and “greenwashing.” This is why widely accepted standards—such as GRI or ISO guidelines—are essential to ensure that numbers are not only accurate but also comparable across industries.

What the Future Holds

The journey toward greener production is still evolving. With technologies like digital twins, artificial intelligence, and advanced analytics, tracking impact will become more detailed and precise. Factories might soon have live dashboards that show exactly how much carbon, water, or waste is linked to each product rolling off the line.

This trend is shaping education as well. Engineering programs are adapting, teaching students to integrate sustainability into every aspect of design and production. Many of the best private engineering colleges in India have already woven courses on eco-friendly manufacturing and sustainable practices into their curriculum, preparing graduates to lead this transformation.

Looking at the Bigger Picture

At its heart, sustainability metrics are not about ticking boxes or satisfying regulators. They represent a deeper shift in how industries define value. It’s no longer enough to be productive; companies must also be protective—of air, water, land, and people.

Industrial engineers are uniquely positioned to make this happen. Their blend of systems thinking and problem-solving allows them to measure what matters, act on insights, and guide industries toward long-term resilience. When sustainability becomes part of day-to-day operations rather than an afterthought, businesses don’t just survive—they earn trust, stay competitive, and leave a lasting positive mark.

The message is clear: measuring impact is the first step, but turning those insights into meaningful change is where true progress lies.