In the realm of advanced manufacturing, Rotary Axis Machining has emerged as a game-changing technology, offering unparalleled precision and versatility in creating complex geometries and parts. Whether you are in the automotive, aerospace, or medical industry, rotary axis machining ensures that every component, from intricate gears to circular parts, is crafted with exceptional accuracy and repeatability.

What is Rotary Axis Machining?

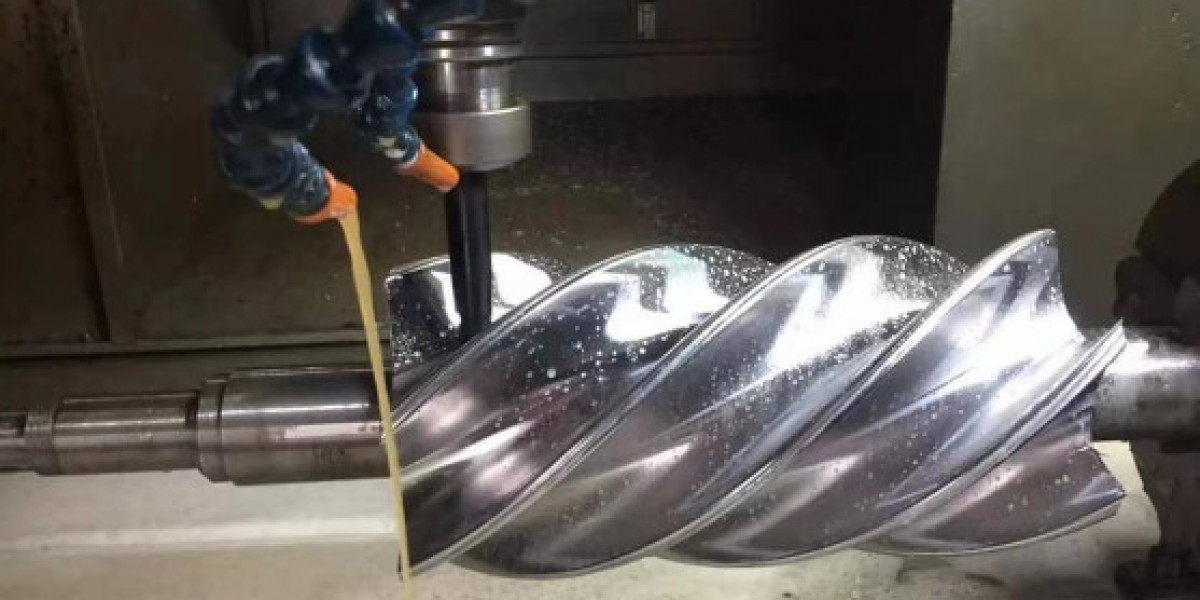

Rotary axis machining refers to a process where an additional rotational axis is added to a CNC machine, allowing it to rotate the workpiece in sync with the movement of the cutting tool. This results in the ability to machine parts that require multi-dimensional cutting, enabling the creation of complex and detailed features on cylindrical, spherical, and other non-flat surfaces.

At its core, rotary axis machining utilizes rotary cutters and a CNC rotary axis to move the workpiece in multiple directions, adding new layers of flexibility and capabilities to CNC machining operations. The ability to rotate the workpiece while the cutting tool simultaneously performs operations such as drilling, milling, or engraving ensures that a wider range of components can be manufactured with high precision.

Key Components in Rotary Axis Machining

To better understand the efficiency of rotary axis machining, let's look at the primary components involved:

Rotary Axis (A, B, and C Axes): The additional rotational axes are often referred to as A, B, and C. These allow the workpiece to rotate around different axes in synchronization with the cutting tool's movements. A typical CNC machine will have three main axes (X, Y, Z), but the addition of one or more rotary axes extends the machining capabilities significantly.

CNC Machine with Rotary Table: The workpiece is mounted on a rotary table, which rotates the part while the CNC machine handles other cutting operations. The rotary table ensures that the part is held securely while enabling the cutting tool to access different surfaces of the component.

Cutting Tools: These are the primary elements for shaping the material. Specialized cutting tools, such as rotary cutters or drills, are often used in rotary axis machining for intricate cutting, shaping, and finishing.

CNC Controller: The heart of any CNC machine is the controller, which translates the programmed instructions (G-code) into mechanical movements. In rotary axis machining, this controller manages the additional rotational movements, coordinating them with the machine’s linear movements to create highly accurate parts.

The Advantages of Rotary Axis Machining

1. Enhanced Precision and Detail

Rotary axis machining is renowned for its ability to produce extremely detailed and intricate parts that are simply not possible with traditional milling or turning methods. With the help of multiple axes, rotary axis machining allows manufacturers to create complex shapes like gears, cams, and other circular components with precision and repeatability.

2. Increased Efficiency

With rotary axis machining, there is no need for multiple setups. Unlike conventional methods where a workpiece must be manually repositioned to machine different faces, the added rotational axis means that parts can be machined in a continuous process. This reduces downtime and enhances overall manufacturing efficiency.

3. Versatility Across Industries

From automotive to aerospace, and even medical device manufacturing, rotary axis machining offers versatile applications. In industries that demand high-precision parts, such as aerospace, rotary axis machining ensures that components meet stringent tolerances and material specifications. Likewise, automotive manufacturers use rotary axis machining to create gears and cams, while the medical industry benefits from its ability to produce components like implants with complex geometries.

4. Ability to Machine Complex Parts in One Setup

One of the standout benefits of rotary axis machining is its ability to handle complex parts that require multi-dimensional cuts, all in a single setup. Parts like turbine blades, aerospace components, or medical devices often have intricate surfaces that need multiple angles of cutting. Rotary axis machining minimizes setup times and errors, as the part remains fixed in the same position throughout the process.

5. Consistent Quality

The CNC-controlled nature of rotary axis machining means that each part produced is identical, ensuring consistent quality and reduced variability. This is crucial in industries that demand high-quality standards, such as aerospace and medical device manufacturing.

Applications of Rotary Axis Machining

Here are some of the most common applications of rotary axis machining:

Automotive Industry: Parts like gears, cams, and shafts that require precision turning and milling are frequently manufactured using rotary axis machining. This process allows for accurate detailing on circular components.

Aerospace Manufacturing: Rotary axis machining plays a key role in creating complex parts like turbine blades, structural components, and engine parts. These parts require high levels of accuracy and often have irregular or curved surfaces that are well-suited to rotary machining techniques.

Medical Devices: From implants to surgical tools, the medical field benefits greatly from the precision and flexibility of rotary axis machining. The ability to machine complex geometries and fine details ensures that medical components are functional, safe, and of high quality.

Tool and Die Making: In tool and die manufacturing, rotary axis machining is often used to create intricate shapes on molds, cutting tools, and dies that require precise details and finish quality.

Energy Sector: Rotary axis machining is ideal for creating components used in energy production, such as parts for turbines or reactors, which demand high tolerances and durability.

Rotary Axis Machining in CNC Systems

The integration of rotary axis technology into CNC systems offers manufacturers advanced capabilities for producing complex parts with greater efficiency. Many modern CNC machines feature multiple rotary axes, allowing the machining of parts with varying degrees of complexity. These machines are used extensively in aerospace, automotive, and defense industries where precision, efficiency, and quality are critical.

In addition to the basic three axes (X, Y, and Z), the inclusion of A, B, and C axes enhances the machine's ability to tackle more challenging tasks. For instance, a 5-axis CNC machine with rotary axis capabilities is particularly adept at machining parts with complex geometries such as turbine blades or intricate molds.

Conclusion

Rotary axis machining is undeniably one of the most important developments in modern CNC technology, offering manufacturers the ability to produce intricate, high-precision parts more efficiently and at a faster rate than ever before. Whether it’s creating detailed automotive components, intricate aerospace parts, or medical implants, rotary axis machining is the key to unlocking precision and versatility in manufacturing.

With its ability to reduce production times, enhance flexibility, and provide consistently high-quality results, rotary axis machining is transforming industries by pushing the boundaries of what can be achieved with CNC technology.

Embrace the future of manufacturing with rotary axis machining—the ultimate solution for precision, speed, and efficiency across a wide range of industries.