These machines provide efficient solutions for producing high-quality, consistent components across a wide range of industries, including automotive, aerospace, and electronics. Whether you're producing parts for high-performance applications or intricate designs, roller die machines offer unmatched efficiency, accuracy, and versatility. In this blog, we’ll explore the inner workings of roller die machines, their key benefits, and why they are indispensable for modern manufacturing processes.

What is a Roller Die Machine?

A roller die machine is a type of machine used in the forming and shaping of materials, typically metals, into specific profiles or parts. The process involves the use of rollers that gradually shape the material as it passes through the machine. Unlike traditional die-casting methods, roller die machines operate through a continuous process, applying pressure to the material to form intricate shapes without the need for additional tooling for each piece.

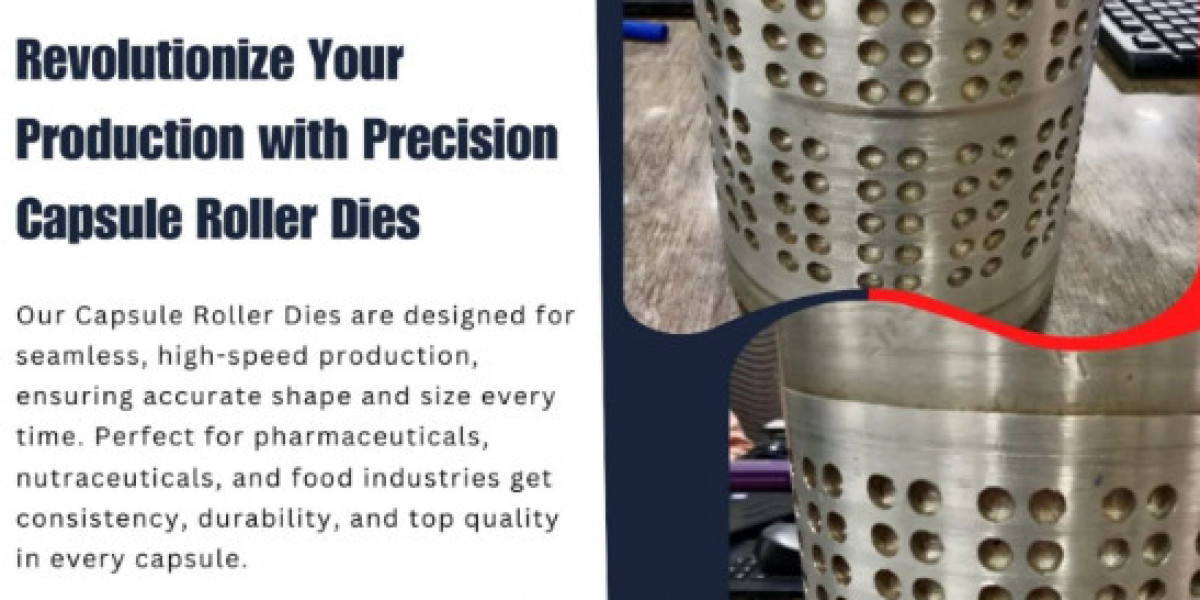

The roller die machine uses two or more rollers, often made of hardened steel or other durable materials, to apply constant pressure to the workpiece. The material, typically metal or plastic, is fed into the machine, where it undergoes a series of progressive deformations to create the desired shape.

How Does a Roller Die Machine Work?

The process of using a roller die machine for manufacturing is relatively straightforward, but it requires precise control and high-quality rollers to ensure smooth operations. Here’s how the process works:

Material Feeding: The material is fed into the roller die machine, typically in the form of a flat strip or sheet. It can be made of various materials, including steel, aluminum, copper, and plastics, depending on the application.

Roller Alignment: The rollers in the machine are aligned in a way that the material is subjected to precise, controlled pressure. Each roller progressively shapes the material by applying pressure at specific points to form the required profile.

Shaping the Material: The material is passed through a set of rollers, each applying pressure to gradually form it into the desired profile or shape. The rollers rotate at precise speeds to ensure that the material is shaped evenly and accurately.

Finishing the Part: Once the material has passed through the rollers, it is cut or separated into individual parts, which may undergo additional processes like heat treatment, surface finishing, or further shaping depending on the required specifications.

Types of Roller Die Machines

Roller die machines come in various configurations depending on the complexity and size of the parts being produced. Some of the most common types include:

Single-Stage Roller Die Machines: These are used for simple, straightforward applications where the material needs to be shaped into a basic profile or design. Single-stage roller die machines are often used for mass production of components that require minimal shaping.

Multi-Stage Roller Die Machines: For more complex parts, multi-stage roller die machines are employed. These machines apply multiple stages of deformation to create intricate shapes, often used in industries like aerospace or automotive, where precision is critical.

Precision Roller Die Machines: These machines are designed for high-precision applications where tight tolerances and detailed profiles are required. They are commonly used in industries such as electronics, where small and complex parts need to be formed with high accuracy.

Key Advantages of Roller Die Machines

1. High Efficiency and Speed

One of the standout benefits of roller die machines is their speed and efficiency. Unlike traditional forming methods, which may require multiple tooling changes and stops, roller die machines continuously shape material as it passes through the rollers. This reduces downtime and speeds up production, making it ideal for mass production of parts.

2. Precision and Accuracy

Roller die machines excel in producing parts with high levels of precision. The rollers are engineered to provide consistent pressure, ensuring that the material is shaped evenly throughout the entire process. This high degree of accuracy is essential in industries that require exact specifications, such as aerospace, automotive, and medical device manufacturing.

3. Cost-Effectiveness

Due to the continuous nature of the roller die machine process, there is a significant reduction in material waste and tool wear. The reduced need for frequent tooling changes or additional equipment results in cost savings over time, making roller die machines a cost-effective solution for high-volume manufacturing.

4. Versatility in Material Usage

Roller die machines can be used with a wide variety of materials, including metals like aluminum, copper, steel, and brass, as well as plastics and composites. This versatility makes roller die machines suitable for a diverse range of industries and applications, from manufacturing automotive parts to creating intricate components for electronics.

5. Consistency in Production

Another benefit of roller die machines is the ability to produce large quantities of parts with consistent quality. Since the process is automated, each part produced is nearly identical to the last, ensuring high levels of uniformity and reducing the likelihood of defects. This consistency is particularly important in industries where reliability and performance are critical.

Applications of Roller Die Machines

Roller die machines are used in a variety of industries to produce parts that require intricate designs and high precision. Some common applications include:

Automotive Industry: Roller die machines are often used to produce automotive components such as brackets, clips, and trim pieces. These parts require precise shaping and are typically produced in large volumes.

Aerospace: The aerospace industry benefits from roller die machines due to their ability to create high-precision parts such as structural components, wing profiles, and engine parts. The accuracy and reliability of roller die machines are essential in ensuring the safety and performance of aerospace components.

Electronics: Many electronic components, including connectors, housings, and heat sinks, are produced using roller die machines. The ability to produce small, detailed parts with high precision makes these machines invaluable in the electronics industry.

Medical Devices: Roller die machines are used to produce medical components such as surgical instruments, implants, and diagnostic tools. The high level of accuracy and precision required in medical device manufacturing makes roller die machines a critical tool in the industry.

Construction and HVAC: Parts such as pipes, ducts, and other structural components used in construction and HVAC systems are often produced using roller die machines. The ability to form large sections of material quickly and accurately makes roller die machines ideal for these applications.

Maintenance and Care of Roller Die Machines

To ensure optimal performance and longevity of your roller die machine, regular maintenance and care are necessary. Key maintenance tasks include:

Lubrication: Ensure the rollers and other moving parts are regularly lubricated to prevent friction and wear.

Roller Alignment: Periodically check that the rollers are properly aligned to avoid deformation of the material and maintain uniform pressure.

Cleaning: Keep the machine clean to prevent material buildup, which could affect the precision of the machining process.

Conclusion

Roller die machines have revolutionized the manufacturing industry by providing an efficient, precise, and cost-effective method for producing high-quality parts. Whether used in the automotive, aerospace, electronics, or medical device industries, roller die machines offer a reliable solution for mass production of intricate components.

With their ability to work with a wide variety of materials, provide exceptional accuracy, and improve production efficiency, roller die machines continue to be a valuable tool in modern manufacturing. By incorporating these machines into your production process, you can achieve faster lead times, higher precision, and reduced costs – making them an essential part of your manufacturing toolkit.

For more information on roller die machines and how they can enhance your manufacturing process, explore trusted suppliers who offer cutting-edge roller die technology to meet your production needs.