The 3D printing materials market is experiencing unprecedented growth, driven by advancements in additive manufacturing technologies and rising adoption across multiple industries. This market intelligence report highlights the critical developments, trends, and opportunities shaping the landscape, offering valuable insights for businesses, manufacturers, and investors seeking to capitalize on the expanding 3D printing ecosystem.

Market Overview

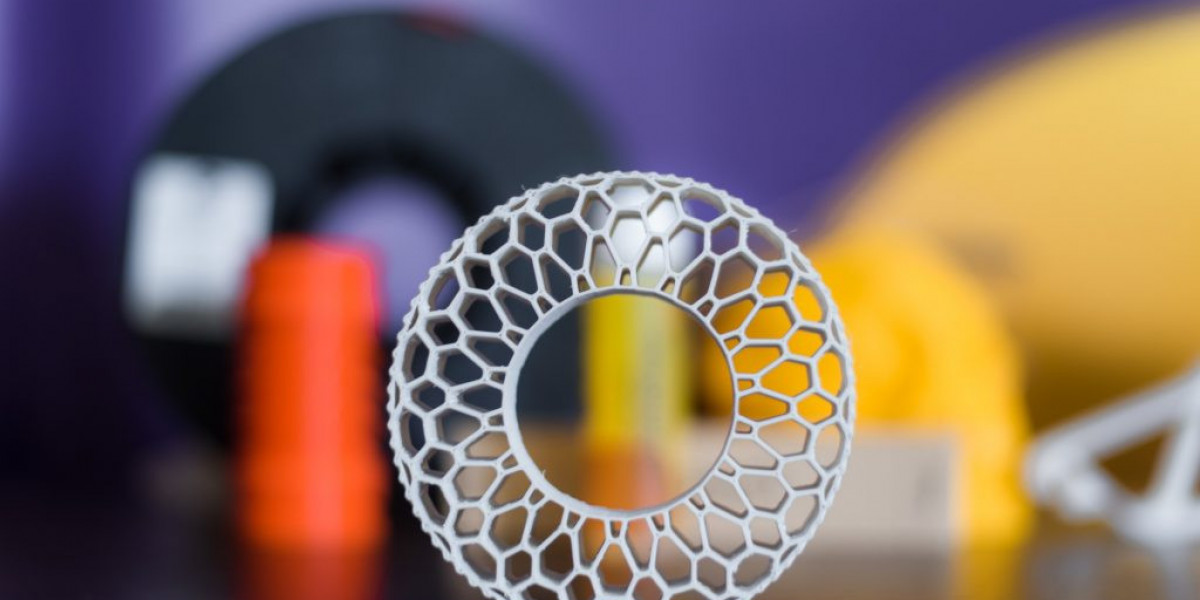

3D printing, also known as additive manufacturing, has revolutionized the way products are designed and manufactured. Unlike traditional subtractive methods, 3D printing builds objects layer by layer, reducing waste, enhancing design flexibility, and enabling rapid prototyping. The materials used in this process are crucial, influencing product quality, durability, and performance. As industries seek efficiency, customization, and sustainability, the demand for advanced 3D printing materials has surged globally.

Key Materials in Demand

The 3D printing materials market encompasses a diverse range of materials tailored to specific applications:

Polymers: ABS, PLA, and PETG remain the most widely used polymers due to their versatility, ease of printing, and cost-effectiveness. Advanced engineering polymers like PEEK and Nylon are increasingly adopted for industrial applications requiring high strength and heat resistance.

Metals: Metal powders, including stainless steel, titanium, and aluminum, are critical for aerospace, automotive, and healthcare industries, enabling lightweight, strong, and highly precise components.

Ceramics: Used in medical implants and electronics, ceramic materials provide biocompatibility and high-temperature resistance.

Composites: Fiber-reinforced composites combine polymers with carbon or glass fibers, offering superior mechanical properties for demanding industrial applications.

Industry Trends and Innovations

Several trends are driving innovation and reshaping the 3D printing materials market:

Sustainable Materials: Biodegradable polymers and recyclable materials are gaining popularity as industries prioritize sustainability and regulatory compliance.

Multi-Material Printing: Advances in printers capable of handling multiple materials simultaneously allow for more complex and functional designs.

Nano-Enhanced Materials: Integration of nanoparticles into polymers improves strength, thermal resistance, and conductivity, expanding material functionality.

Customization and On-Demand Manufacturing: Tailored materials for specific applications enable rapid prototyping and small-batch production, reducing lead times and costs.

Market Drivers

The growth of the 3D printing materials market is fueled by several factors:

Industrial Adoption: Sectors such as aerospace, healthcare, automotive, and consumer electronics increasingly rely on additive manufacturing for lightweight, high-performance components.

Technological Advancements: Continuous improvements in printing technologies and material formulations enhance reliability, precision, and scalability.

Cost Efficiency: Reduced waste, lower production costs for small batches, and minimized inventory needs make 3D printing an attractive alternative to traditional manufacturing.

Innovation in Product Design: The ability to create complex geometries not achievable with conventional methods drives demand for specialized materials.

Regional Insights

North America: A leading adopter due to early technology integration, robust industrial base, and strong R&D investments.

Europe: Focused on automotive, aerospace, and medical applications, with government support for additive manufacturing initiatives.

Asia-Pacific: Rapid industrialization, growing electronics and automotive sectors, and increasing manufacturing automation drive market expansion.

Rest of the World: Emerging markets are gradually adopting 3D printing technologies, particularly in healthcare and construction applications.

Competitive Landscape

The 3D printing materials market is highly competitive, with key players focusing on product innovation, strategic partnerships, and mergers & acquisitions to expand their portfolios. Prominent companies include BASF SE, 3D Systems, Arkema, Evonik Industries, and Stratasys, among others. Continuous investment in R&D ensures the development of high-performance materials catering to specialized industrial requirements.

Future Outlook

The future of the 3D printing materials market is promising, with expected growth driven by:

Expanding industrial applications and end-use sectors.

Development of cost-effective, high-performance, and sustainable materials.

Integration with AI, IoT, and digital manufacturing platforms for smarter production solutions.

Rising adoption in healthcare, construction, and aerospace sectors for complex, customized parts.

Conclusion

Understanding the 3D printing materials market intelligence is essential for stakeholders aiming to navigate the evolving landscape of additive manufacturing. With continuous technological innovations, expanding material options, and growing adoption across industries, businesses have a significant opportunity to capitalize on the transformative potential of 3D printing. Staying informed about market trends, material advancements, and regional dynamics is crucial to maintain a competitive edge and drive future growth in this rapidly evolving sector.