In diligence similar as aerospace, medical bias, automotive, and high- performance artificial operations, the demand for factors that meet extremely tight specifications is ever- growing. CNC precision turning has come a critical process for producing high- forbearance corridor with unmatched delicacy and thickness. still, achieving the asked quality requires further than just advanced ministry it requires a professed and dependable manufacturing mate. opting the right CNC perfection turning mate can make the difference between smooth design prosecution and expensive crimes or detainments.

This companion will explore the crucial factors masterminds and buyers should consider when choosing a CNC perfection turning mate, helping insure that your high- forbearance corridor are delivered with perfection, trustability, and effectiveness.

Understanding CNC Precision Turning

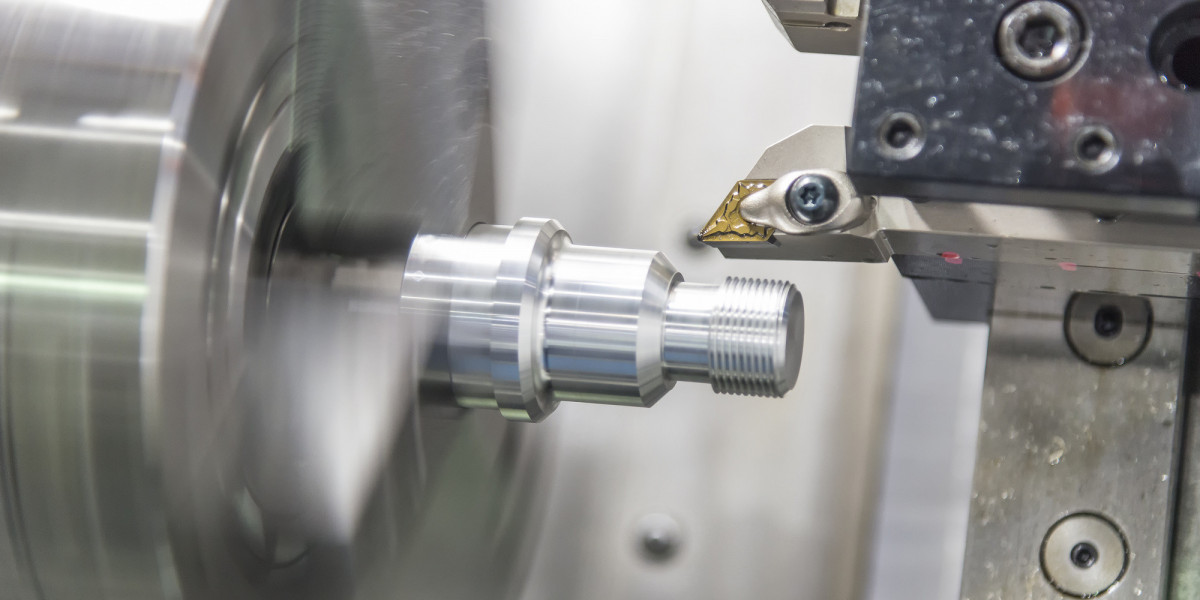

CNC perfection turning is a manufacturing process in which a workpiece rotates while cutting tools remove material according to programmed instructions. Unlike homemade turning, CNC turning uses computer- controlled machines to achieve largely accurate confines and complex shapes. High- forbearance corridor, frequently with forbearance measured in microns, calculate on this technology to meet strict performance norms.

operations of CNC perfection turning include:

- Aerospace fasteners and structural factors

- Medical implants and surgical instruments

- Automotive machine corridor and perfection shafts

- Artificial ministry factors

- Electronics connectors and jackets

By automating the turning process, manufacturers can insure unremarkable results, maintain harmonious quality, and produce corridor that meet exact design specifications.

1. Estimate Technical Capabilities

Not all CNC perfection turning mates have the same specialized capabilities. When assessing implicit mates, consider:

- Multi-axis CNC lathes: Multi-axis machines enable the product of complex shapes in a single setup, reducing crimes and perfecting thickness.

- robotization: Automated tool changers and part running ameliorate speed, reduce mortal error, and increase product effectiveness.

- Secondary machining capabilities: Some corridor bear drilling, milling, threading, or other operations. mates with in- house secondary machining save time and reduce handling crimes.

- Material versatility: insure the manufacturer can handle the accoutrements needed for your design, whether essence like titanium, aluminum, pristine sword, or advanced plastics.

A mate with robust specialized capabilities can deliver high- forbearance corridor constantly, reducing rework and product detainments.

2. Check Quality Control Processes

High- forbearance corridor demand strict quality control. Ask implicit CNC perfection turning mates about their quality assurance procedures:

- Coordinate Measuring Machines( CMMs): For precise dimensional verification.

- Ray and optic examination systems: descry face defects and corroborate figure.

- Material testing: Confirms mechanical parcels, chemical composition, and strength.

- Statistical Process Control( SPC): Observers product trends and catches diversions beforehand.

A mate that combines automated examination tools with mortal oversight ensures every element meets exact specifications before it leaves the installation.

3. Confirm instruments and Assiduity Compliance

instruments demonstrate a manufacturer's commitment to quality and nonsupervisory compliance. For high- forbearance corridor, look for:

- ISO 9001: General quality operation norms.

- AS9100: Aerospace-specific quality conditions.

- IATF 16949: Automotive assiduity quality norms.

- ISO 13485: Medical device manufacturing standard.

These instruments insure your CNC perfection turning mate follows standardized processes, attestation practices, and nonstop enhancement protocols.

4. Assess Experience and Assiduity moxie

Experience matters when producing high- forbearance corridor. A mate familiar with your assiduity will more understand material parcels, machining challenges, and nonsupervisory conditions. estimate:

- Times of experience in CNC perfection turning and high- forbearance product

- Track record with analogous systems or corridor

- customer references or case studies

- Knowledge of assiduity-specific challenges

An educated mate can anticipate implicit issues, recommend design advancements, and help you achieve your design pretensions efficiently.

5. Examine Communication and Collaboration

Effective collaboration is essential for high- perfection systems. Your CNC perfection turning mate should offer:

- Design support: Feedback on manufacturability, cost- effectiveness, and forbearance.

- Transparent communication: Updates on product progress, implicit issues, and delivery timelines.

- Problem- working: amenability to work collaboratively on grueling corridor or custom conditions.

A mate who communicates easily and proactively can help detainments, reduce crimes, and ameliorate overall design issues.

6. Consider Lead Times and Scalability

High- forbearance corridor frequently bear both prototypes and product runs. Ask your mate about:

- Typical lead times for prototypes and product orders

- Capability to gauge product from small batches to high- volume runs

- force operation or just- by- time delivery options

A mate who can gauge with your requirements ensures that your force chain remains flexible and responsive.

7. Review outfit conservation and Technology Investment

CNC perfection turning relies on advanced ministry that must be duly maintained. A dependable mate invests in:

- Regular estimation and conservation of CNC machines

- ultramodern multi-axis lathes and robotization outfit

- Software updates for CAD/ CAM and machine controls

This commitment to technology and keep ensures harmonious delicacy, reduces time-out, and extends the life of the outfit used to produce your high- forbearance corridor.

8. Estimate Pricing with Value in Mind

While cost is a factor, it should n't overweigh quality and trustability. High- forbearance corridor bear perfection, moxie, and rigorous quality assurance, which come with applicable costs. Look for a CNC perfection turning mate who:

- Offers transparent pricing without retired freights

- Provides cost-effective results without compromising quality

- Supports design optimization to reduce material waste and machining time

fastening on value rather than the smallest price ensures long- term savings and reliable performance.

Allied Technologies International Inc Experts in CNC Precision Turned corridor

For masterminds and manufacturers seeking high- quality CNC precision turned parts, Allied Technologies International Inc is a trusted mate. Specializing in titanium and other advanced accoutrements , Allied Technologies International Inc combines state-of-the-art CNC ministry with rigorous quality control to deliver factors that meet the tightest forbearance and assiduity norms. Their moxie spans aerospace, medical, automotive, and artificial operations, icing every part performs reliably under demanding conditions. Partnering with Allied Technologies International Inc guarantees perfection, thickness, and long- term performance for indeed the most complex systems.

Conclusion

opting the right CNC perfection turning mate for high- forbearance corridor is pivotal for design success. masterminds and buyers should precisely estimate specialized capabilities, quality control processes, instruments, assiduity experience, communication, scalability, outfit conservation, and value. A professed mate not only produces corridor to exacting specifications but also adds value through collaboration, invention, and harmonious performance.

Investing the time to choose the right CNC perfection turning mate ensures that high- forbearance factors are delivered with perfection, trustability, and effectiveness, helping your business match strict norms while minimizing pitfalls and costs.