Carbon fiber wrapping has become a popular solution for reinforcing and repairing concrete structures. This advanced technique uses high-strength carbon fiber sheets or fabrics applied to existing structural elements, enhancing their load-bearing capacity. Civil engineers and contractors prefer this method due to its durability, lightweight nature, and ability to address structural weaknesses without extensive demolition or reconstruction. It is widely used in residential, commercial, and industrial buildings.

What is Carbon Fiber Wrapping?

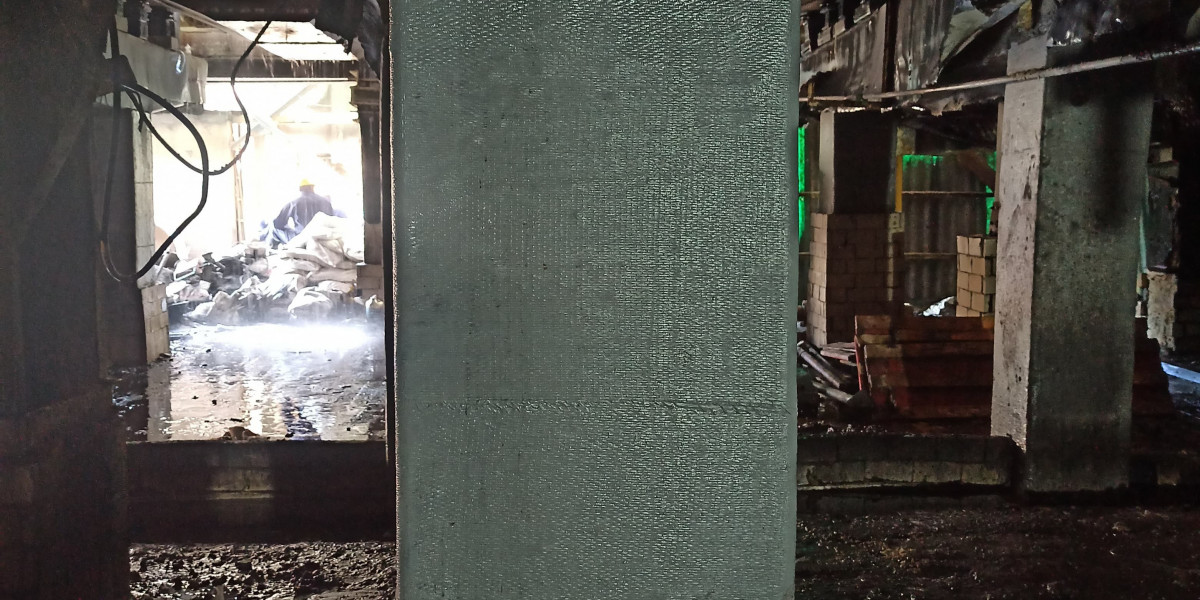

Carbon fiber wrapping involves applying carbon fiber sheets to structural elements such as beams, columns, and slabs. The carbon sheets are bonded using specialized epoxy resins, creating a strong composite that improves the structure's strength. This method is particularly useful for retrofitting older buildings, repairing damaged concrete, or preventing potential structural failures. It ensures long-term stability while maintaining a minimal impact on the existing design.

Advantages of Carbon Fiber Wrapping

One of the main advantages of carbon fiber wrapping is its high tensile strength, which can significantly improve a structure's capacity to withstand heavy loads. Unlike traditional reinforcement methods, it is lightweight and easy to install, reducing labor and project time. Carbon fiber wrapping also resists corrosion and environmental damage, making it ideal for areas exposed to moisture, chemicals, or seismic activity, ensuring a longer lifespan for reinforced structures.

Applications of Carbon Fiber Wrapping

Carbon fiber wrapping is used in multiple structural applications. Engineers commonly apply it to strengthen concrete beams, columns, slabs, and walls. It is also effective in repairing earthquake-damaged buildings or upgrading structures to meet modern load requirements. Bridges, parking structures, and industrial facilities benefit from carbon fiber reinforcement. The method adapts to different shapes and surfaces, providing a flexible solution for both small-scale residential projects and large infrastructure developments.

Carbon Fiber Wrapping vs Traditional Reinforcement

Traditional reinforcement methods often involve steel plates or concrete jacketing, which can be heavy, time-consuming, and expensive. Carbon fiber wrapping offers a superior alternative with its lightweight, flexible sheets that require minimal surface preparation. Unlike steel, carbon fiber does not corrode, reducing long-term maintenance costs. Additionally, its quick application ensures faster project completion without compromising structural safety or aesthetics, making it a cost-effective solution for modern construction projects.

The Installation Process

The carbon fiber wrapping process starts with cleaning and preparing the surface of the concrete element. Any cracks or damaged areas are repaired using epoxy or mortar. Next, the carbon fiber sheets are cut to size and coated with epoxy resin before being applied. Skilled technicians ensure proper adhesion and alignment to maximize strength. The process is efficient, leaving the structure ready for immediate use, which is particularly beneficial in time-sensitive construction or repair projects.

Common Mistakes to Avoid

While carbon fiber wrapping is highly effective, incorrect installation can reduce its benefits. Common mistakes include improper surface preparation, uneven application of epoxy, or incorrect fiber orientation. It is crucial to hire experienced contractors who understand material properties and follow manufacturer guidelines. Regular inspections and quality checks during installation ensure the reinforced structure performs as intended, providing long-term durability and safety.

Carbon Fiber Wrapping for Earthquake Resistance

In earthquake-prone areas, carbon fiber wrapping plays a critical role in improving structural safety. It enhances the ductility and load-bearing capacity of concrete elements, allowing buildings to better absorb seismic forces. By reinforcing columns, beams, and walls, carbon fiber helps prevent catastrophic failures during earthquakes. Retrofitting older structures with this method is a cost-effective way to comply with updated building codes and protect both property and lives.

Maintenance and Longevity

One of the key benefits of carbon fiber wrapping is its minimal maintenance requirements. Unlike steel reinforcement, carbon fiber is resistant to corrosion, chemicals, and moisture. Periodic inspections are recommended to check for any surface damage, but the overall lifespan of a wrapped structure can exceed decades. This durability ensures a long-term solution for structural safety, reducing the need for frequent repairs and offering peace of mind to property owners.

Choosing the Right Contractor

Selecting the right contractor is crucial for the success of carbon fiber wrapping projects. Look for companies with proven experience, certified technicians, and a strong portfolio of completed projects. A reliable contractor will assess the structure, recommend appropriate reinforcement strategies, and ensure precise installation. Quality workmanship guarantees that the reinforced structures achieve the desired strength, durability, and safety standards.

Carbon fiber wrapping is a modern, efficient solution for strengthening and repairing concrete structures. Its lightweight, durable, and versatile nature makes it suitable for residential, commercial, and industrial applications. By enhancing load-bearing capacity, providing earthquake resistance, and offering long-term durability, this method addresses both structural and economic concerns. Hiring experienced contractors ensures proper installation, maximizing the benefits of carbon fiber wrapping for lasting safety and reliability.