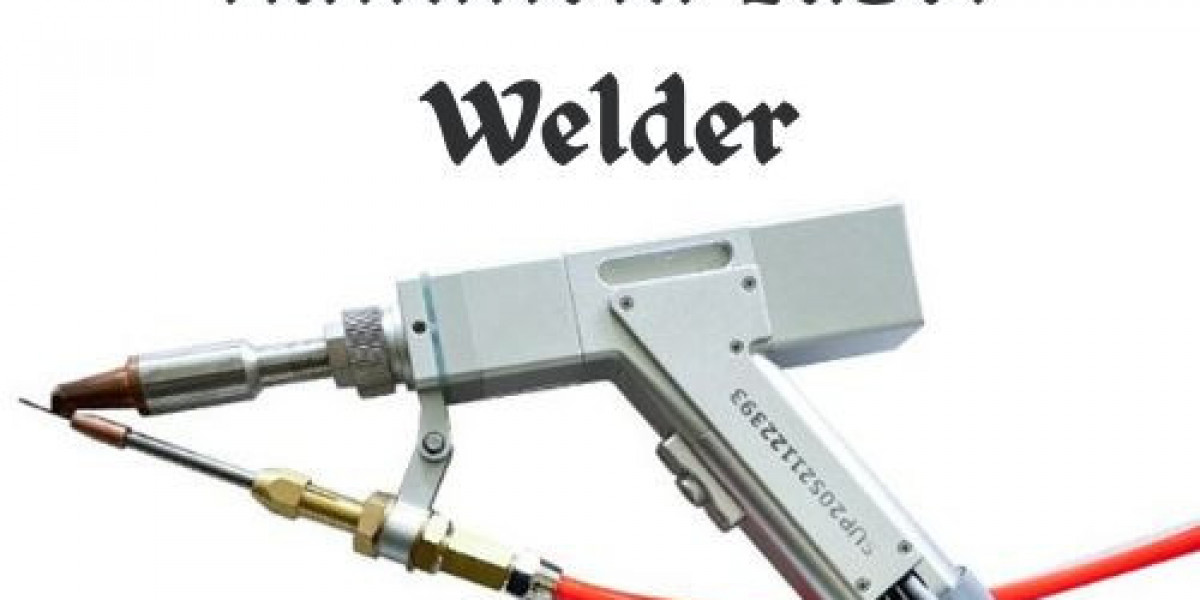

A handheld laser welder combines portability with power. This tool allows operators to execute precise, clean welds without being tied down to stationary machinery. It offers flexibility in working with complex shapes, large structures, and areas where conventional welding tools might be difficult to maneuver. Beyond the simplicity of its portability, the handheld laser welder brings consistency and speed, which are highly valued in industries where time and quality are crucial.

How the Handheld Laser Welder Works

The handheld laser welder operates by directing a focused laser beam onto the materials being joined. This laser generates heat, melting the surfaces of the metals and fusing them together. The precision of the beam means minimal material distortion and reduced heat-affected zones. This is especially beneficial when working with thin sheets of metal, delicate components, or high-value parts where mistakes can be costly.

Unlike other methods, the handheld laser welder requires minimal filler material, and in many cases, none at all. The result is a smoother weld surface that often needs little or no post-processing. The welding process is not only cleaner but also faster, making it a preferred solution for production environments where efficiency matters.

Applications of the Handheld Laser Welder

The versatility of the handheld laser welder makes it a practical tool across a wide range of industries. From small workshops to large-scale manufacturing, it addresses various challenges and requirements.

1. Automotive Industry

The automotive sector demands welding solutions that balance strength with precision. The handheld laser welder is used in body repair, exhaust system assembly, and component fabrication. Its portability allows technicians to repair difficult-to-reach areas on vehicles without dismantling major parts.

2. Aerospace and Aviation

In aerospace, every component must meet strict standards of safety and performance. The handheld laser welder helps in repairing engine parts, aluminum structures, and other lightweight yet strong alloys used in aircraft manufacturing. Its ability to create clean welds ensures that the material integrity is preserved.

3. Electronics and Electrical Manufacturing

Miniaturization in electronics requires welding methods that don’t damage sensitive components. A handheld laser welder provides the accuracy needed for fine wires, small connectors, and intricate parts, ensuring strong joints without excess heat.

4. Medical Equipment

The medical sector often requires tools and equipment made from stainless steel and titanium. The handheld laser welder is applied in manufacturing surgical instruments, implants, and other precision devices, where reliability and cleanliness of welds are critical.

5. Metal Fabrication and Repair Workshops

Small and medium enterprises benefit greatly from the handheld laser welder. From custom metal fabrication to repair services, it offers flexibility for working on jobs of varying sizes and complexities without requiring bulky setups.

Why Industries Are Turning to the Handheld Laser Welder

Industrial demand for precision, efficiency, and flexibility has grown significantly. Traditional welding systems often require extensive operator skill and involve larger setups, which can slow down processes. The handheld laser welder addresses these challenges.

Operators appreciate its ergonomic design, which makes it easier to handle during extended periods of use. Businesses see the value in its ability to reduce time spent on secondary processes such as grinding, polishing, or reworking joints. The smooth weld seams and reduced splatter save both time and resources, aligning with modern production goals.

Training and Skill Requirements

While traditional welding methods may take years to master, the handheld laser welder is comparatively straightforward to operate. Basic training can prepare technicians to use the tool effectively. This means that companies can adopt the technology quickly and put it into operation without long delays.

The simplicity of operation also reduces the risk of errors, allowing new users to produce high-quality results without compromising safety. This accessibility makes it a suitable solution for workshops looking to modernize their welding practices.

Materials Compatible with the Handheld Laser Welder

Another strength of the handheld laser welder is its compatibility with a wide range of metals. It can efficiently weld stainless steel, carbon steel, aluminum, copper, and titanium. This versatility allows industries to consolidate their welding needs under a single tool, avoiding the need for multiple specialized machines.

Its effectiveness on reflective metals, which are traditionally difficult to weld with other methods, further highlights its usefulness in industries that rely on these materials.

Growth of Handheld Laser Welder in Global Markets

The global market is seeing a rising demand for handheld laser welders. Manufacturing industries worldwide are upgrading from traditional methods to laser-based welding because it helps them stay competitive.

Countries with strong manufacturing bases—such as China, Germany, the United States, and Japan—are leading in the adoption of this technology. At the same time, smaller workshops and businesses in developing markets are starting to recognize its value. This global trend indicates that handheld laser welders are not just a temporary innovation but a long-term shift in welding practices.

Future Potential of the Handheld Laser Welder

The potential of the handheld laser welder extends beyond its current applications. As industries continue to seek efficiency and sustainability, the demand for tools that save energy and reduce waste will grow. The handheld laser welder, with its ability to deliver precise, clean welds with minimal resources, aligns with these future goals.

Additionally, as technology improves, newer models are expected to become even more compact, efficient, and accessible. The development of advanced cooling systems, improved safety features, and increased automation integration will enhance its usability across sectors.

Final Thoughts

The handheld laser welder is more than just a portable welding tool; it is a game-changer in industrial practices. Its ability to combine precision, speed, and versatility makes it a valuable solution for industries ranging from automotive to aerospace, electronics to medical equipment, and beyond. With global adoption on the rise, it represents the future of welding—where efficiency meets accuracy in a flexible, user-friendly package.