In the automotive industry, innovation continues to drive the development of advanced manufacturing equipment, and one essential piece of technology is the plastic tank welding machine. Designed specifically to handle the unique requirements of fuel tanks, coolant reservoirs, and other essential plastic components, these machines ensure reliable performance, precision, and durability. Modern custom-built versions of these machines offer cutting-edge features that make them indispensable in the automotive sector, improving both efficiency and product quality.

High Precision Welding Capabilities

One of the standout features of a modern custom automotive plastic tank welding machine is its ability to perform highly precise welding operations. Automotive tanks require seamless and leak-proof joints to ensure safety and compliance with industry standards. The advanced technology integrated into these machines enables consistent welds with minimal margin of error. The precision is often supported by programmable settings and sensors that monitor every aspect of the process, reducing the likelihood of defects and rework.

Customizable Design for Automotive Applications

A key advantage of modern welding machines is their ability to be customized to meet the specific needs of automotive manufacturers. Each type of tank, whether for fuel, air, or coolant, may have unique structural and material requirements. A custom plastic tank welding machine can be tailored with specialized molds, tooling, and welding heads to match these demands. This customization ensures that manufacturers achieve optimal results while maintaining flexibility across different production lines.

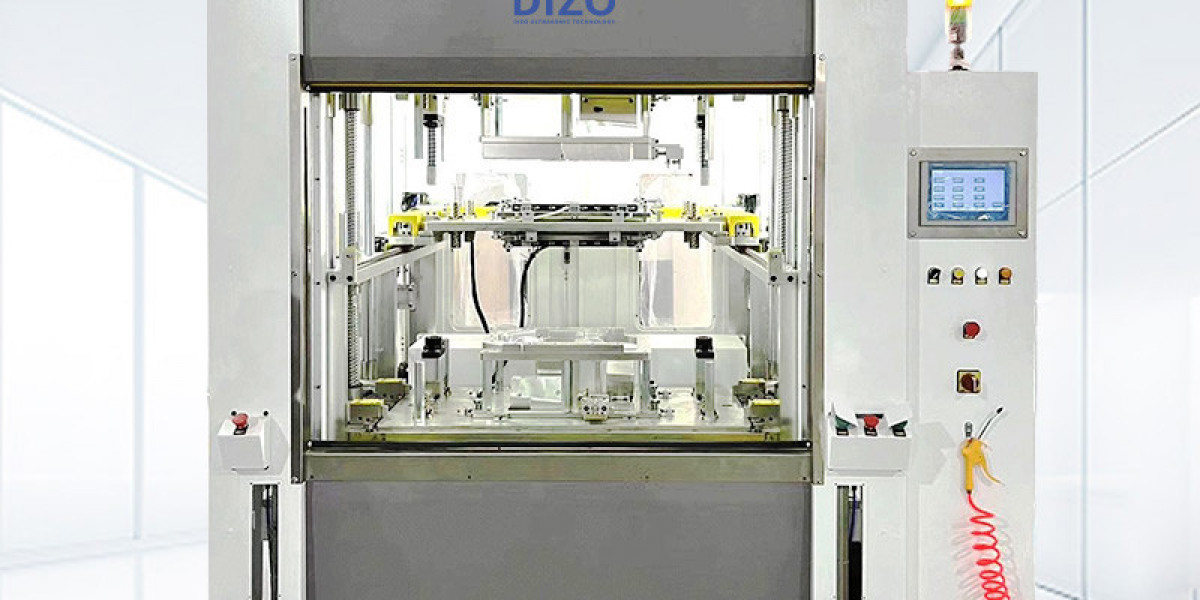

Integration of Automated Control Systems

Automation has transformed the welding industry, and automotive plastic tank machines are no exception. Modern units often come equipped with advanced control panels, touch-screen interfaces, and programmable logic controllers. These features allow operators to input precise parameters for welding speed, temperature, and pressure. Additionally, automated controls reduce human error, ensure repeatability, and make the overall production process more efficient. The combination of automation with real-time data monitoring makes these machines reliable for high-volume automotive manufacturing.

Energy Efficiency and Cost Savings

Energy efficiency is another hallmark of modern welding equipment. A custom plastic tank welding machine is designed to minimize energy consumption without compromising output quality. These machines often use optimized heating systems and intelligent energy management, reducing electricity costs for manufacturers. With sustainability becoming a growing priority in the automotive sector, energy-efficient machines align with eco-friendly production practices and help companies reduce their carbon footprint.

Durability and Robust Construction

Automotive production environments demand machinery that can withstand continuous, heavy-duty use. Modern welding machines are built with high-quality components and durable materials to ensure long service life. Their robust construction enables them to operate effectively under demanding conditions, maintaining consistent performance over time. This reliability minimizes downtime and maintenance costs, providing manufacturers with an efficient long-term investment.

Advanced Safety Features

Safety is a critical factor in any automotive manufacturing facility. Modern plastic tank welding machines are equipped with features such as protective enclosures, emergency shut-off systems, and heat-resistant barriers. Sensors are often integrated to detect irregularities in the welding process and automatically halt operations when necessary. These safety features not only protect operators but also help safeguard expensive equipment and materials.

Compatibility with Different Plastic Materials

Automotive tanks can be made from a variety of plastics, including polyethylene, polypropylene, and other high-performance polymers. A modern welding machine offers the flexibility to work with multiple materials, adapting welding techniques to achieve strong, durable bonds. This versatility is essential for manufacturers who produce different types of tanks for varying automotive applications. By accommodating a wide range of plastics, the machine ensures greater adaptability in production.

Enhanced Production Speed and Output

In the competitive automotive industry, speed is a crucial factor in maintaining profitability. Modern custom welding machines are designed to increase production speed while maintaining quality standards. Automated loading and unloading systems, rapid heating elements, and streamlined workflows all contribute to faster cycle times. With enhanced output, manufacturers can meet growing demands without compromising efficiency or accuracy.

Conclusion

The modern custom automotive plastic tank welding machine is an essential innovation for today’s automotive manufacturing industry. Its features, ranging from precision welding and customizable design to automated control systems and energy efficiency, highlight its importance in delivering reliable and durable plastic tanks. Enhanced safety measures, compatibility with various materials, and improved production speed further establish its role as a cornerstone of modern automotive manufacturing. As the industry continues to evolve, these machines will remain at the forefront of producing high-quality, leak-proof, and environmentally friendly plastic tanks that meet the growing demands of the global automotive market.