In today’s rapidly evolving industrial landscape, precision, speed, and reliability are no longer optional—they’re essential. One technology that continues to redefine these standards is optic fiber welding. This advanced process is enabling manufacturers to achieve higher efficiency, seamless results, and long-term durability across multiple industries. Among the leading innovators driving this change is LaserChina, a trusted name in high-performance laser systems and precision welding equipment.

Understanding the Power of Optic Fiber Welding

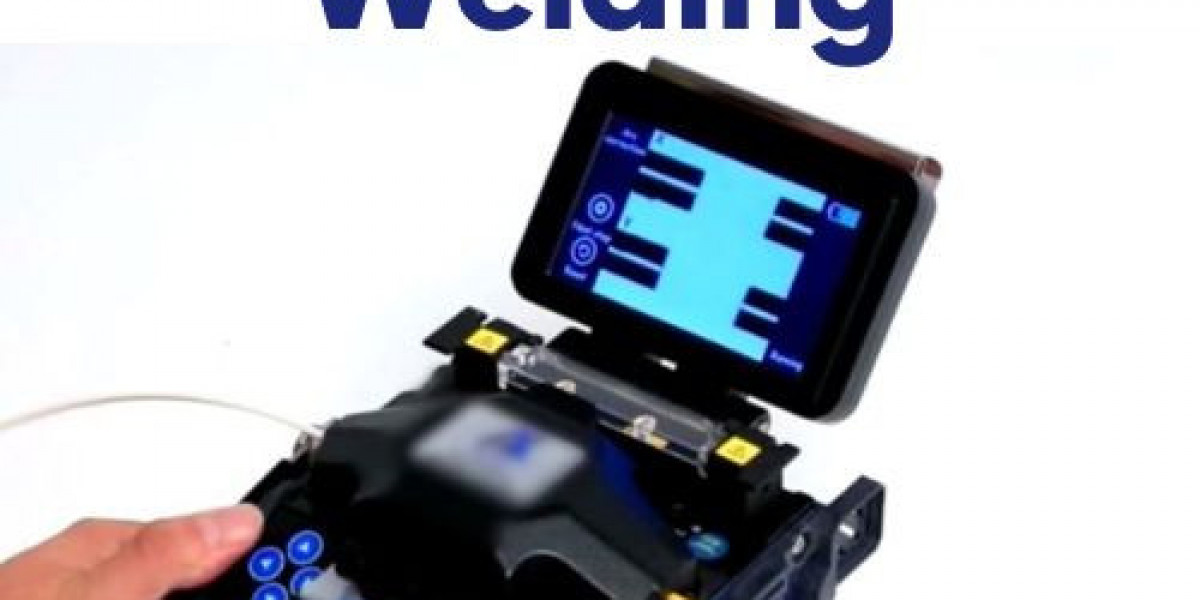

Optic fiber welding, often referred to as fiber laser welding, is a process that uses a highly focused laser beam to join metal components with incredible precision. Unlike traditional welding techniques that rely on physical contact or filler materials, fiber laser systems deliver concentrated energy through optical fibers, resulting in faster welding speeds, deeper penetration, and minimal distortion.

This process is ideal for industries that demand clean, accurate welds—such as aerospace, automotive, medical device manufacturing, and electronics. The result is a more stable structure, improved production efficiency, and reduced operational costs.

Why Manufacturers Are Switching to Fiber Laser Systems

Manufacturers are increasingly choosing optic fiber welding systems over conventional methods for several key reasons. First, they offer superior beam quality, which ensures consistent weld seams even on complex materials like stainless steel, titanium, or aluminum. Second, fiber laser systems are energy-efficient and require less maintenance compared to older CO₂ laser machines or arc welding setups.

Another major advantage is automation. Modern fiber laser welders, like those developed by LaserChina, can be easily integrated into robotic systems, enabling continuous, high-speed production. This reduces human error while maintaining unmatched precision—a must for industries that can’t afford even the slightest deviation in weld quality.

Applications Across Diverse Industries

The versatility of optic fiber welding makes it suitable for a wide range of applications. In the automotive industry, it’s used for producing high-strength components like gears, sensors, and battery cases for electric vehicles. Medical device manufacturers rely on it to assemble surgical tools and implantable devices, where precision and sterility are critical.

In the electronics sector, fiber laser welding ensures micro-joining of delicate parts such as connectors, sensors, and microcircuits without damaging surrounding materials. Even in aerospace and defense, where reliability under extreme conditions is vital, optic fiber welding has become the preferred method for producing lightweight yet strong components.

The LaserChina Advantage

When it comes to choosing the right laser solution provider, experience and innovation matter. LaserChina has built a strong reputation as a pioneer in the field of laser technology, offering state-of-the-art systems designed to meet the most demanding production standards. Their comprehensive range of laser welding machines, laser marking systems, and cutting solutions reflects a deep understanding of industry needs.

Each LaserChina system is engineered for maximum efficiency, delivering high stability, low maintenance, and precise control. Whether for small-scale workshops or large manufacturing facilities, their products combine reliability with user-friendly operation. Furthermore, LaserChina’s commitment to research and development ensures that customers benefit from continuous innovation and access to the latest advancements in fiber laser technology.

Key Benefits of Choosing LaserChina’s Fiber Welding Systems

1. Superior Beam Quality: LaserChina’s equipment ensures consistent, high-intensity laser output, resulting in flawless weld seams with minimal spatter.

2. High Efficiency: Their systems can operate continuously, dramatically increasing throughput while lowering operational costs.

3. Flexible Integration: Whether used manually or within automated production lines, LaserChina’s machines adapt seamlessly to different setups.

4. Long Lifespan and Low Maintenance: Designed with durability in mind, these systems require minimal service, ensuring long-term return on investment.

5. Expert Support: Beyond the product itself, LaserChina offers exceptional technical support, training, and customization options tailored to client requirements.

Innovation at the Core of Modern Manufacturing

As global manufacturing continues to evolve, the demand for precision welding technologies like optic fiber welding is only growing stronger. From compact handheld units to high-powered industrial models, the flexibility of fiber laser solutions makes them indispensable tools for modern production environments.

LaserChina remains at the forefront of this transformation, providing advanced laser systems that empower businesses to scale faster, enhance product quality, and stay competitive in an increasingly automated world.

Final Thoughts

The future of manufacturing lies in technologies that deliver both precision and performance—and optic fiber welding stands out as one of the most transformative solutions available today. With its ability to produce cleaner welds, reduce waste, and streamline production, it’s no surprise that companies across industries are making the switch.