Piping estimators play a crucial role in the construction and industrial sectors. Whether you're estimating for a residential plumbing job or a large-scale industrial piping system, accurate estimating can make or break a project. For beginners, the world of piping estimating services can seem complex, but with the right knowledge and tools, you can quickly become confident in providing high-quality, reliable estimates.

In this blog post, we’ll break down what makes piping estimating services "the best," provide a step-by-step guide to mastering the process, and offer practical tips to ensure your estimates are as accurate and efficient as possible. Let’s dive in!

Introduction: The Role of Piping Estimating Services

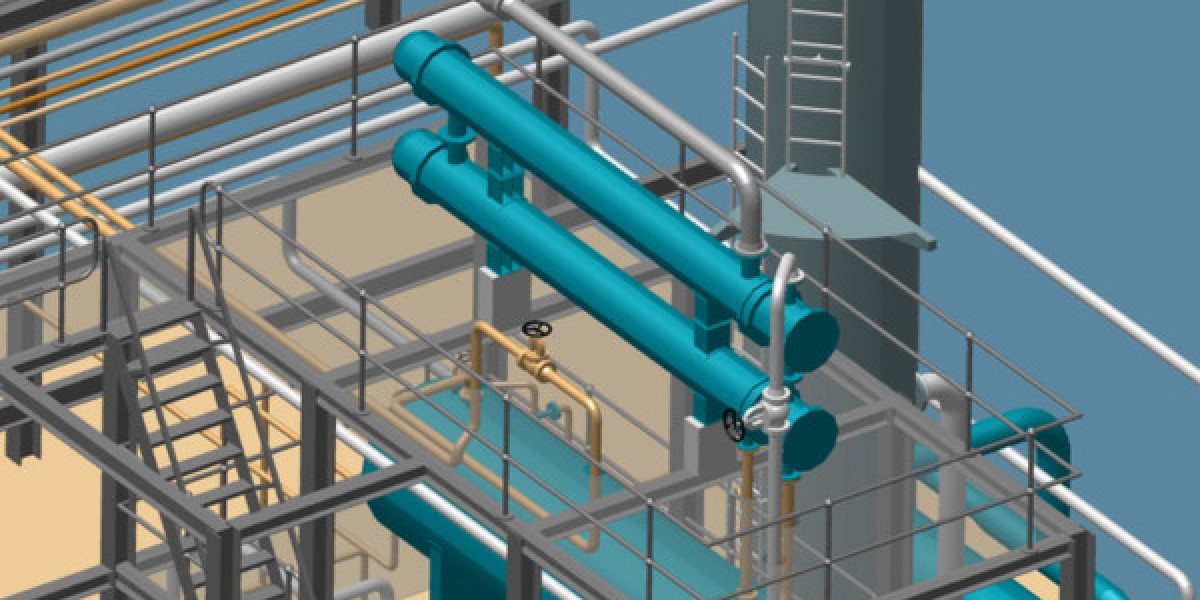

Piping estimating is a specialized skill that involves calculating the costs associated with piping materials, labor, and other factors that contribute to the installation or replacement of pipes in residential, commercial, or industrial settings. Whether you’re estimating for plumbing, heating, ventilation, or cooling systems, a piping estimate ensures that the project stays within budget, meets deadlines, and is completed without any major financial surprises.

For beginners, piping estimating might feel intimidating, but it doesn’t have to be! With the right guidance and techniques, you can confidently estimate the scope, costs, and time required for any piping project. Let’s walk through how to get the best results for your piping estimating services, step by step.

Step 1: Understand the Project Scope and Gather Information

The first step in providing top-notch piping estimating services is to clearly understand the project’s scope. You can’t estimate costs accurately if you don’t know exactly what needs to be done.

Start by gathering as much information as possible:

- Project Plans and Blueprints: These will help you understand the layout of the piping system, including pipe sizes, types, and installation locations. You’ll also get details about other components, such as valves, fittings, and joints.

- Material Specifications: If the project specifies particular types of pipes (e.g., copper, PVC, steel), these will influence the cost, so make sure you note all material requirements.

- Access Points and Pipe Routing: Identify areas where pipes need to be installed and the complexity of the routing. Hard-to-reach or underground pipes often require more labor and specialized tools, which will affect the estimate.

- Additional Requirements: Is there any welding, special fittings, or pressure testing required? This kind of work needs to be factored into the overall estimate.

Tip: If you're unsure about any aspect of the project, don’t hesitate to ask the project manager or contractor for clarification. Having clear information upfront will save you time and reduce the risk of errors later on.

Step 2: Measure and Calculate Material Requirements

Once you have the project plans in hand, it's time to measure the length and type of piping needed. Calculating the correct quantity of materials is one of the most important steps in piping estimating services, and it’s critical for creating an accurate estimate.

Here’s how to do it:

- Measure the Length of Pipe: Start by measuring the total length of each type of pipe. This is typically done by measuring from the centerline of one fitting to the centerline of the next fitting. Make sure to account for bends, tees, and elbows that may add to the total length.

- Choose the Right Pipe Size: Different jobs require different pipe sizes. Whether it’s for residential plumbing, heating systems, or industrial piping, each size of pipe (e.g., 1-inch, 2-inch, etc.) will have its own cost. Consult the plans to ensure you’re using the correct size for each section.

- Account for Fittings and Accessories: Piping projects often require elbows, tees, couplings, valves, and flanges. You should calculate how many fittings are needed and how this impacts the overall cost. Don’t forget to include additional materials like pipe insulation or hangers if necessary.

Tip: Keep a detailed record of the quantities you’ve measured. Having an organized system will make it easier to create an accurate list of materials and avoid mistakes.

Step 3: Estimate Labor Costs

Labor costs are a large portion of any piping project. To estimate labor accurately, you need to determine the total time required for installation, based on the complexity of the job and the experience level of the workers.

Here’s how to estimate labor:

- Calculate Labor Hours: Break down the project into individual tasks (e.g., cutting, fitting, welding, pressure testing). Estimate how many hours each task will take. You can use industry standards or your own past experience to guide you.

- Determine Labor Rate: Labor rates vary depending on the type of work and the region. You can research local rates for pipe fitters, welders, and plumbers to get a sense of what to charge. Make sure to factor in any overtime or special conditions that could affect the rate.

- Consider Job Complexity: Some jobs are more complex than others. For example, installing piping in a cramped space or on a high-rise building will take more time than a straightforward ground-level installation. Adjust your labor estimate based on the difficulty of the job.

Tip: Don’t forget to account for the time it takes to transport workers, handle materials, and deal with any unexpected delays.

Step 4: Factor in Overhead and Profit Margins

To ensure that your piping estimating services are profitable, you need to include overhead costs and a reasonable profit margin in your estimate.

- Overhead Costs: These include things like office expenses, insurance, equipment maintenance, and administrative costs. Overhead is typically a percentage of the total project cost and is added to the estimate.

- Profit Margin: A typical profit margin for piping estimating services ranges from 10% to 20%, depending on the complexity of the project. You’ll need to decide on a margin that keeps you competitive while also ensuring you make a profit.

Tip: When deciding on your profit margin, consider factors like market competition, the size of the project, and the level of risk involved. Larger projects may warrant a higher profit margin.

Step 5: Review and Finalize Your Estimate

Once you’ve calculated materials, labor, and overhead, it’s time to finalize your estimate. Double-check your numbers to ensure they’re accurate and that you haven’t missed anything important. Create a clear, itemized breakdown that shows the client exactly how the estimate is structured.

Provide a comprehensive estimate that includes:

- Materials cost (pipes, fittings, etc.)

- Labor cost (man-hours, hourly rate)

- Overhead and profit

- Additional costs (e.g., testing, specialized work)

Tip: Transparency is key! Clients appreciate when they understand how their estimate is broken down. Offering a detailed estimate helps build trust and reduces misunderstandings.

Practical Tips for Beginner Estimators

- Use Estimating Software: Estimating software can help streamline your process and reduce errors. Software like Procore, Buildertrend, or Bluebeam can help you quickly calculate material costs, labor hours, and more.

- Work with Templates: Starting with a pre-made template can help you stay organized and ensure you include all necessary elements in your estimates.

- Stay Up to Date on Industry Standards: The piping industry is constantly evolving, with new materials and techniques. Make sure you’re familiar with the latest standards to stay competitive and accurate.

- Collaborate with Other Professionals: Don’t hesitate to reach out to other professionals (e.g., contractors or experienced estimators) for advice or to review your estimates.

Conclusion:

Becoming skilled in piping estimating services takes practice and attention to detail. By following the steps outlined above and continuously improving your knowledge, you'll be on your way to providing high-quality, reliable estimates for any piping project.