How Dry Ice Blasting Solves the Challenges of Industrial Equipment Cleaning

Keeping industrial equipment clean is essential for efficient operation, safety, and product quality. However, many traditional cleaning methods pose serious challenges such as extended downtime, surface damage, exposure to hazardous chemicals, and complicated cleanup processes. This is where dry ice blasting emerges as a powerful solution that addresses these problems in an innovative and eco-friendly way.

In this article, we’ll explore the difficulties faced in cleaning industrial equipment and how dry ice blasting effectively overcomes these hurdles.

Why Cleaning Industrial Equipment Is Challenging

Industrial equipment is exposed to dust, grease, oils, rust, baked-on residues, and other contaminants that degrade performance over time. Cleaning this equipment, however, is not straightforward:

Lengthy Downtime: Many traditional cleaning methods require machines to be stopped, cooled, or even disassembled, halting production and increasing costs.

Risk of Surface Damage: Abrasive cleaning techniques such as sandblasting or scrapers can damage delicate parts, reduce equipment lifespan, or compromise finishes.

Hazardous Chemicals: Chemical cleaners and solvents pose health risks to workers and often require special disposal to avoid environmental harm.

Moisture Issues: Water or solvent-based cleaning can cause corrosion, mold, or electrical damage in sensitive equipment.

Excessive Waste: Abrasive blasting leaves behind media residue that requires additional cleaning and disposal, increasing labor and environmental burdens.

Because of these challenges, companies are searching for a cleaning method that is fast, effective, safe, and environmentally friendly.

What Is Dry Ice Blasting?

Dry ice blasting is a cleaning process that propels tiny pellets of solid carbon dioxide at high speeds onto a surface. Upon impact, the pellets clean by a combination of mechanical action, extreme cold, and sublimation—the dry ice changes instantly from solid to gas, lifting away dirt and contaminants without leaving residue.

This technique uses no water, no abrasive materials, and no harsh chemicals, making it a uniquely dry and clean process.

How Dry Ice Blasting Addresses Industrial Cleaning Problems

1. Dramatically Reduces Downtime

Dry ice blasting can often be performed without taking machines apart or shutting down operations for long periods. Because dry ice sublimates instantly and leaves no moisture, equipment is ready to use immediately after cleaning. This significantly reduces downtime and keeps production on schedule.

2. Protects Equipment Surfaces

Unlike abrasive blasting methods, dry ice blasting is non-abrasive. It removes contaminants gently, without scratching or wearing away metal, plastic, painted surfaces, or delicate electronics. This means your equipment lasts longer and requires fewer repairs.

3. Eliminates Harmful Chemicals

Dry ice blasting uses only carbon dioxide pellets and compressed air, so there are no toxic solvents or chemical residues involved. This reduces health risks for workers and lessens environmental impact—an especially important benefit in food processing, pharmaceutical, and sensitive manufacturing industries.

4. Prevents Moisture-Related Damage

Unlike water or solvent-based cleaning, dry ice blasting leaves no moisture behind, eliminating risks of corrosion, mold growth, or electrical shorts. It’s safe for cleaning motors, circuit boards, and other moisture-sensitive equipment.

5. Simplifies Waste Disposal

Since the dry ice evaporates upon impact, no abrasive media waste is left behind. Cleanup is easier and faster, requiring only the disposal of removed dirt, grease, or coatings.

Industries That Benefit Most from Dry Ice Blasting

Dry ice blasting has found applications in many sectors:

Food and Beverage: Cleans ovens, conveyors, and equipment to maintain hygiene without chemicals.

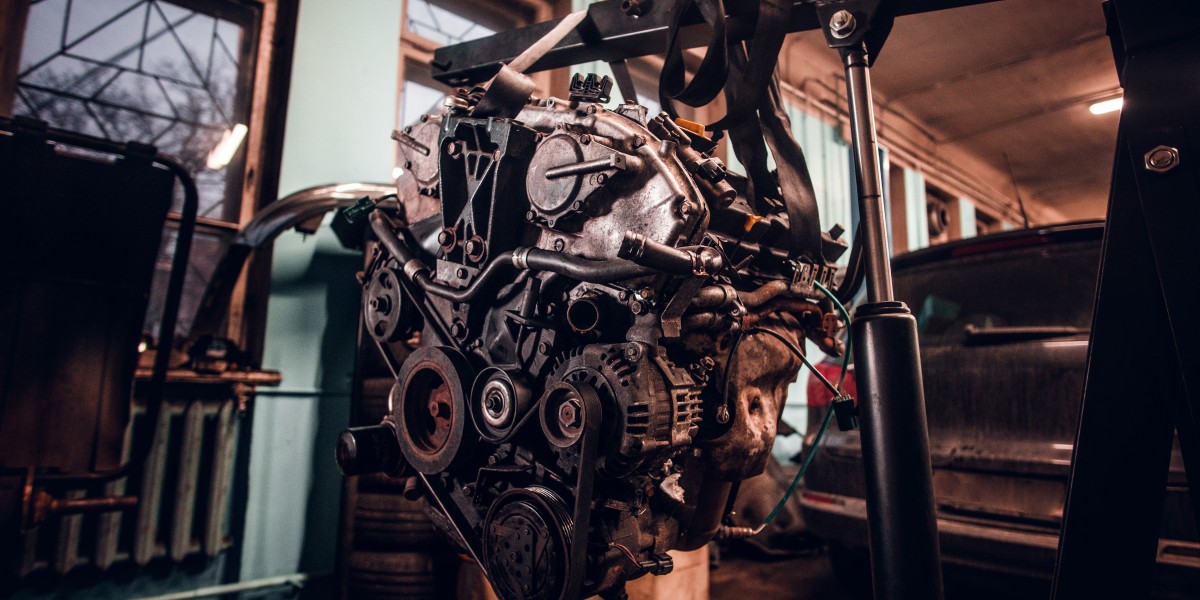

Automotive and Aerospace: Removes grease, paint, and carbon deposits without damaging engines or sensitive parts.

Manufacturing: Cleans molds, presses, and production lines efficiently, minimizing downtime.

Electronics and Electrical: Safely cleans motors, circuit boards, and panels without moisture damage.

Restoration and Remediation: Effectively removes soot, smoke, and mold after fire or water damage.

Its versatility and safety make dry ice blasting a valuable asset in diverse industries.

Why Choose Professional Dry Ice Blasting Services?

Dry ice blasting requires specialized equipment and trained operators for safe, effective cleaning. Working with a professional company like Top Dry Ice ensures proper technique, safety compliance, and optimal results tailored to your equipment and industry.

Their expertise reduces risk, saves time, and maximizes equipment lifespan.

Is Dry Ice Blasting Right for Your Facility?

If your facility struggles with long cleaning downtimes, chemical hazards, moisture risks, or abrasive damage, dry ice blasting may be the solution. It’s ideal for companies that want faster turnaround, safer operations, and environmentally responsible cleaning.

Conclusion

Dry ice blasting is changing how industries clean their equipment by solving many long-standing problems. Its ability to clean effectively without chemicals, moisture, or abrasives makes it an attractive choice for modern industrial maintenance.

For businesses seeking a reliable, efficient, and safe cleaning method, professional dry ice blasting services from companies like Top Dry Ice offer proven results with minimal disruption.

Embrace the future of industrial cleaning by exploring dry ice blasting today.