Introduction

The rivet gun market developments are increasingly shaped by material durability, heat-resistant innovations, and high-performance fastening solutions. Industrial demands for reliable, long-lasting, and high-temperature-resistant tools are driving manufacturers to focus on advanced alloys, composite materials, and reinforced structures. Insights into the rivet gun market reveal that these developments are critical for sectors such as aerospace, automotive, construction, and heavy machinery, where fastening precision and tool longevity are paramount.

The rivet gun market potential is expanding as manufacturers invest in materials and designs that withstand harsh operational conditions, including high torque, extreme temperatures, and repetitive usage. Tools that combine durability and performance are being rapidly adopted across both industrial and professional DIY applications.

Advanced Material Durability

Advanced material durability is a central driver of rivet gun market developments. Manufacturers are using high-strength steel, titanium alloys, and carbon-fiber composites to enhance tool lifespan and withstand rigorous fastening operations. These materials enable rivet guns to maintain performance without warping, cracking, or wearing down over time.

rivet gun market insights indicate that material durability is particularly essential in aerospace and automotive assembly, where precision and reliability cannot be compromised. Companies focusing on long-lasting, robust tools are achieving competitive advantages and expanding their market presence.

Heat-Resistant Innovations

Heat-resistant innovations are transforming rivet gun market developments. Tools exposed to high friction, continuous operation, or extreme environmental temperatures require materials that can endure heat without losing structural integrity or performance. Manufacturers are incorporating heat-treated alloys, thermal-resistant coatings, and reinforced mechanical systems to meet these requirements.

The rivet gun market benefits from heat-resistant designs as industries such as aerospace, automotive, and heavy machinery demand tools capable of performing under elevated temperatures. Heat-resistant rivet guns reduce operational downtime and ensure consistent fastening quality in demanding conditions.

High-Performance Fastening Solutions

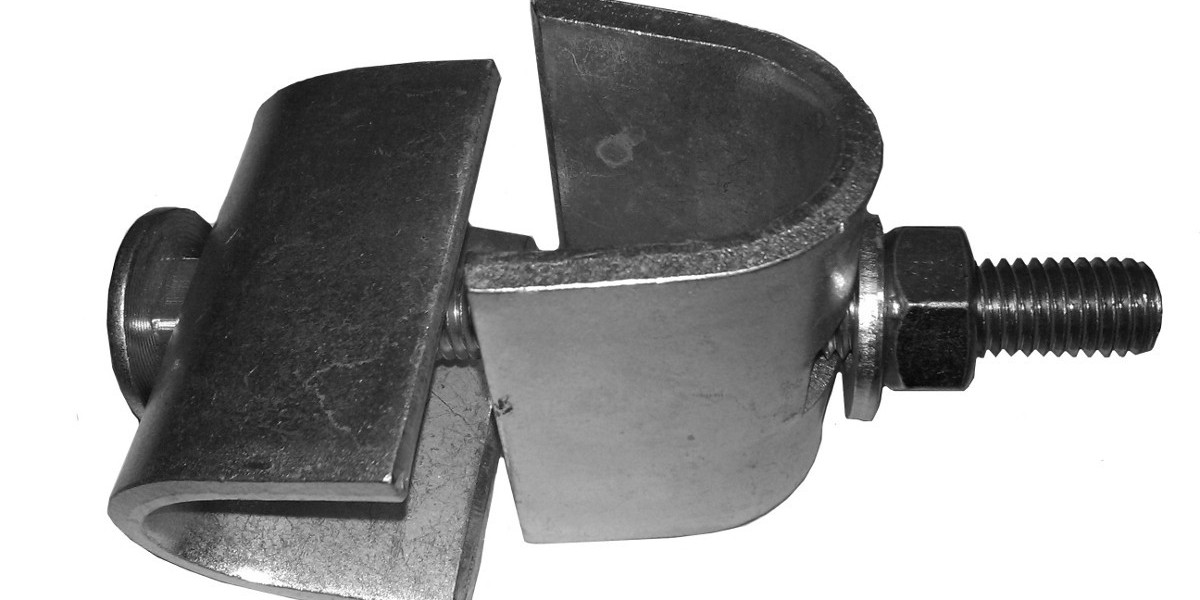

High-performance fastening solutions are reshaping rivet gun market developments. Tools designed for precise torque control, rapid fastening cycles, and compatibility with various rivet types enhance productivity and assembly quality. Advanced fastening mechanisms, including adjustable torque systems and reinforced jaws, are critical for industrial applications.

rivet gun market insights suggest that high-performance rivet guns are increasingly adopted in construction, aerospace, and electronics sectors. By providing reliable, accurate, and high-speed fastening capabilities, manufacturers can differentiate products and secure broader industrial adoption.

Lightweight and Reinforced Tool Designs

While durability and heat resistance are essential, lightweight and reinforced tool designs are gaining traction in the rivet gun market. Balancing strength with weight optimization reduces operator fatigue and improves handling during prolonged operations. Reinforced components enhance structural integrity without compromising maneuverability.

The rivet gun market potential is further enhanced as ergonomic, lightweight, and reinforced designs increase usability and efficiency across industrial sectors. Aerospace and automotive manufacturers, in particular, benefit from tools that combine robustness with operational comfort.

Industrial Adoption and Sector-Specific Trends

Industrial adoption of durable, heat-resistant, and high-performance rivet guns is growing across multiple sectors. Aerospace manufacturers require precision fastening tools capable of withstanding high temperatures and repeated use. Automotive production lines demand high-speed, durable tools compatible with advanced assembly processes.

Construction, infrastructure, and industrial machinery sectors increasingly rely on reinforced, heat-resistant tools to maintain efficiency, safety, and consistency during complex operations. rivet gun market developments indicate that sector-specific requirements are critical drivers of innovation and adoption.

Regional Market Dynamics

Regional trends play a significant role in rivet gun market developments. North America and Europe are early adopters of durable, heat-resistant, and high-performance tools due to stringent industrial standards and advanced manufacturing infrastructure. Manufacturers in these regions emphasize precision, longevity, and reliability.

Asia-Pacific is emerging as a key growth region for high-performance rivet guns. Rapid industrialization, growing infrastructure projects, and expansion of manufacturing hubs are fueling demand for durable and heat-resistant tools. Latin America and the Middle East are gradually incorporating advanced fastening solutions, offering opportunities for global manufacturers.

Innovation and Competitive Differentiation

Innovation in material durability, heat resistance, and high-performance fastening differentiates manufacturers in the rivet gun market. Companies developing tools with reinforced structures, advanced alloys, and precision fastening mechanisms attract industrial clients seeking reliability, efficiency, and longevity.

The rivet gun market potential is further strengthened when durability, heat resistance, and high-speed fastening capabilities are combined with ergonomic design and sector-specific adaptability. Manufacturers offering advanced tools that meet stringent operational requirements secure stronger market positioning.

Challenges and Strategic Approaches

Despite the clear advantages, challenges exist in implementing durable and heat-resistant technologies in the rivet gun market. High material costs, complex production processes, and balancing weight with strength are notable obstacles.

Strategic approaches include investing in R&D, optimizing material usage, providing performance guarantees, and tailoring tools to sector-specific demands. By addressing these challenges, manufacturers can maximize rivet gun market adoption and ensure long-term customer satisfaction.

Future Growth Outlook

The rivet gun market developments indicate strong growth potential driven by material durability, heat-resistant innovations, and high-performance fastening solutions. Industrial demand for robust, reliable, and efficient tools is expected to rise across aerospace, automotive, construction, and heavy machinery sectors.

Companies investing in advanced materials, reinforced designs, and high-performance mechanisms are likely to capture substantial market share. rivet gun market insights suggest that durability, heat resistance, and precision fastening will define the next phase of global growth and adoption.

Conclusion

The rivet gun market developments are increasingly influenced by material durability, heat-resistant innovations, and high-performance fastening solutions. Tools designed to withstand harsh conditions, repeated use, and elevated temperatures are gaining adoption across multiple industrial sectors.

Manufacturers prioritizing reinforced materials, thermal resilience, and precision fastening capabilities are positioned to lead the rivet gun market. By aligning product innovation with sector-specific requirements, companies can strengthen market presence, drive adoption, and ensure sustainable growth in the evolving global rivet gun market.