Introduction to Slat Conveyor: Powering Industrial Efficiency

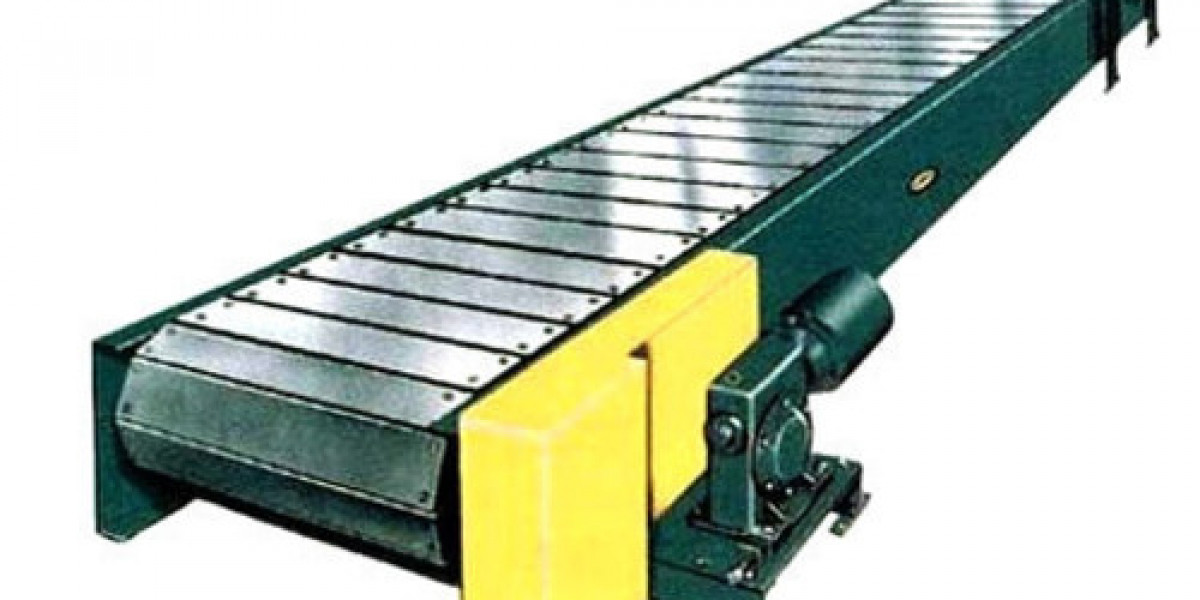

In today's competitive industrial landscape, efficient material handling can make or break your operational productivity. Among the various solutions available, the slat conveyor stands out as a robust, versatile workhorse capable of transforming your production and distribution processes. These systems utilize interconnected slat typically made from durable materials like steel, plastic, or alloy to transport items that would challenge conventional conveyor systems.

For businesses in Northern India, particularly in Delhi and Saharanpur, UP, accessing reliable slat conveyor manufacturers has become increasingly important for maintaining competitive advantage in sectors ranging from automotive and manufacturing to food processing and pharmaceuticals. These systems excel where ordinary conveyor systems fail—handling heavy, bulky, or irregularly shaped items with precision and reliability.

This comprehensive guide explores everything you need to know about slat conveyor technology, its applications, benefits, and how to select the right slat conveyor manufacturers for your specific operational requirements.

What Exactly is a Slat Conveyor?

A slat conveyor is a heavy-duty conveyor system designed with interconnected slat attached to a chain mechanism. Unlike traditional belt-based systems, these slat create a continuous rigid surface that provides exceptional stability for transported items. This fundamental design difference makes this technology ideal for handling products that are too large, heavy, hot, or irregularly shaped for conventional conveyor systems.

The robust construction of this equipment enables it to perform in demanding environments where other conveyor would deteriorate quickly. From extreme temperature conditions to harsh industrial settings, these industrial workhorses maintain operational integrity while transporting everything from delicate food products to massive engine blocks.

Beyond these standard specifications, leading slat conveyor manufacturers offer custom engineering to meet specific application requirements, including specialized dimensions, unique material compositions, and tailored control systems.

Types of Slat Conveyor and Their Applications

Slat conveyor technology comes in various configurations, each designed to address specific operational needs and space constraints:

Straight Slat Conveyor: The most common configuration, straight slat conveyor , transport items in a direct linear path. Ideal for assembly lines, packaging operations, and straightforward point-to-point transportation needs, these units provide reliable performance with minimal complexity.

Curved Slat Conveyor: Engineered to navigate factory space constraints, curved slat conveyor redirect goods along predetermined angles (typically 30°, 45°, or 90°). This equipment eliminates the need for multiple straight conveyor and transfer stations, reducing both equipment costs and floor space requirements.

Elevating Slat Conveyor: Designed for multi-level operations, elevating slat conveyor efficiently transport materials between different elevations. Featuring anti-slip partitions, these industrial workhorses safely move products between floors or between different processing heights within the same facility.

Heavy-Duty Slat Conveyor: Built with reinforced materials and robust chain mechanisms, heavy-duty slat conveyor handle extreme loads that would overwhelm standard systems. Engineered for transporting engine blocks, machinery components, and other substantial items, these units feature sturdy frames and high-capacity drives.

Plastic Slat Conveyor: Utilizing high-strength polymers like POM or PVC, plastic slat conveyor offer excellent corrosion resistance for industries with strict hygiene requirements. Lightweight yet durable, they are particularly valued in food processing, pharmaceutical, and beverage applications where chemical resistance and easy cleaning are priorities.

Material Options for Slat Conveyor

The performance characteristics of this equipment largely depend on the materials used in its construction:

Steel Slat: Superior durability defines steel slat conveyor , making them ideal for harsh conditions and heavy-impact applications. Steel slat maintain integrity under extreme temperatures and continuous heavy loading, outperforming other materials in rugged industrial environments.

Plastic Slat: Corrosion-resistant properties make plastic slat conveyor the preferred choice for wet environments, washdown areas, and industries with strict hygiene standards. The lightweight nature of this equipment also reduces power requirements and simplifies maintenance procedures.

Hardwood Slat: Exceptional impact absorption makes hardwood slat conveyor ideal for protecting finished products from scratches or denting. The natural cushioning effect of wood provides a protective transport surface for painted items, delicate components, or products where surface quality is critical.

Formed or Structural Channel Slat: Enhanced rigidity characterizes formed or structural channel slat conveyor, which provide additional reinforcement for extreme load conditions. These specialized designs can support both the transported items and onboard tooling or operator work platforms.

Key Benefits of Implementing Slat Conveyor

Investing in a well-designed slat conveyor delivers substantial operational advantages:

Exceptional Load Capacity: The rigid slat design enables transportation of items that would damage or overwhelm conventional conveyor systems, with some models handling loads exceeding 10,000 pounds.

Enhanced Durability: Engineered for longevity, quality equipment from reputable slat conveyor manufacturers withstands demanding operating conditions that would quickly degrade less robust alternatives, ensuring years of reliable service with proper maintenance.

Continuous Operation Capability: Unlike manual handling or some automated alternatives, this technology supports non-stop production cycles, dramatically reducing downtime and increasing overall throughput.

Space Optimization: With configurations including straight-line, curved, and elevating designs, this equipment can be tailored to maximize efficiency in virtually any factory layout, no matter how constrained.

Reduced Maintenance Requirements: The straightforward mechanical design translates to simpler maintenance procedures, easier component replacement, and lower lifetime maintenance costs compared to more complex alternatives.

Precision Handling: By providing a stable, rigid transport surface, this technology maintains precise product positioning throughout the transportation process, enabling seamless integration with automated assembly, packaging, and robotic systems.

Industry-Specific Applications

The versatility of this technology makes it suitable for diverse industrial sectors:

Automotive and Heavy Manufacturing: In the automotive sector, this equipment transports engines, transmission assemblies, and complete vehicle frames through assembly stations. Their robust construction supports these substantial components while maintaining precise positioning for both robotic and manual assembly operations.

Food and Beverage Processing: The food industry benefits from hygienic units constructed with stainless steel or FDA-approved plastics that withstand rigorous cleaning protocols. This equipment transports raw ingredients, partially processed goods, and packaged products through various production stages while meeting strict food safety standards.

Pharmaceutical Manufacturing: Precision handling defines the pharmaceutical application of this technology, where it transports vials, blister packs, and packaging materials through controlled environments. The stability provided prevents product damage while maintaining sterile conditions.

Warehousing and Logistics: Modern distribution facilities utilize this equipment for efficient sortation, accumulation, and transportation of packaged goods. Its ability to handle varied package sizes and weights makes it ideal for mixed-SKU environments common in e-commerce and third-party logistics.

Appliance Manufacturing: The assembly of large appliances like refrigerators, washing machines, and ovens requires heavy-duty support that this technology provides. Some designs even incorporate workstations directly into the conveyor line, allowing operators to perform assembly tasks while products move steadily through the production process.

Selecting the Right Slat Conveyor Manufacturers: Key Considerations

Choosing an appropriate slat conveyor manufacturers requires careful evaluation of several critical factors:

Technical Expertise and Experience: Look for slat conveyor manufacturers with proven experience in designing and implementing this equipment for your specific industry. Review case studies and request references to verify their capability to handle applications similar to yours.

Customization Capabilities: The best slat conveyor manufacturers offer extensive customization options, including tailored dimensions, specialized materials, and unique configurations to match your operational workflow and physical space constraints.

Quality of Components and Construction: Investigate the materials and components used in their equipment. Reputable slat conveyor manufacturers utilize high-quality chains, drives, and structural elements to ensure long-term reliability and performance.

After-Sales Support and Service: Confirm the availability of comprehensive support services, including installation supervision, operator training, preventive maintenance programs, and prompt spare parts availability.

Cost Versus Value Analysis: While initial cost matters, prioritize total value, including energy efficiency, maintenance requirements, operational lifespan, and potential productivity gains when evaluating proposals from slat conveyor manufacturers.

Maintenance Guidelines for Optimal Slat Conveyor Performance

Proper maintenance ensures the longevity and reliability of your investment:

Regular Inspection Routines: Establish scheduled inspections of slat, chains, bearings, and drive mechanisms to identify wear before it causes system failures.

Appropriate Lubrication Practices: Follow recommendations from your slat conveyor manufacturers for lubricant types and application frequencies to minimize friction and prevent premature component wear.

Load Capacity Adherence: Strictly observe published load limits to prevent structural damage, chain strain, and premature wear that result from overloading.

Hygiene and Cleaning Protocols: Implement regular cleaning procedures appropriate for your industry, particularly for food, pharmaceutical, or other applications where contamination control is critical.

Proper Chain Tension Maintenance: Monitor and adjust chain tension according to the specifications from your slat conveyor manufacturers, as either excessive tightness or looseness can lead to operational issues and accelerated wear.

Frequently Asked Questions About Slat Conveyor

What is the typical lifespan of a well-maintained slat conveyor?

With proper maintenance and adherence to operating guidelines, a quality unit from a leading slat conveyor manufacturers can provide 10-15 years of reliable service. Regular inspection, appropriate lubrication, and timely component replacement significantly extend operational lifespan.

Can slat conveyor be integrated with other types of conveyor?

Yes, this technology readily integrates with various conveyor types, including roller, belt, and overhead systems. This flexibility allows designers to create optimized material handling solutions that leverage the strengths of different technologies for specific applications.

How do I determine the appropriate load capacity for my application?

Calculate the maximum weight your system will transport, including containers or pallets, then add a safety margin of 15-20%. Reputable slat conveyor manufacturers can help with this calculation and recommend appropriate specifications for your specific needs.

What industries most commonly use slat conveyor technology?

Major industries utilizing this equipment include automotive manufacturing, food processing, pharmaceuticals, electronics, warehousing, logistics, and heavy equipment manufacturing. Any industry requiring reliable transportation of heavy, bulky, or irregular items can benefit from this technology.

Are plastic slat conveyor as durable as steel versions?

While steel systems generally offer higher absolute strength, modern engineering-grade plastics provide excellent durability with superior corrosion resistance. The choice depends on your specific application requirements, environmental conditions, and load characteristics.

Can slat conveyor handle incline and decline applications?

Yes, specialized designs with cleats or traction surfaces effectively transport materials on inclines up to 45 degrees in some configurations. The rigid slat construction provides superior stability on inclined paths compared to flexible belt systems.

Conclusion: Making the Right Investment in Material Handling

This equipment represents a strategic investment in operational efficiency, product handling capability, and long-term productivity. For businesses in Delhi, Saharanpur, and throughout Northern India, selecting the appropriate slat conveyor manufacturers in india requires careful consideration of technical capabilities, industry experience, and service support.

By understanding the various types, materials, and configurations available, you can make an informed decision that aligns with your specific operational requirements and business objectives. The right equipment will not only solve immediate material handling challenges but will also provide a foundation for future growth and operational excellence.

When evaluating potential slat conveyor manufacturers, prioritize those with demonstrated expertise in your industry, robust engineering capabilities, and comprehensive after-sales support. This due diligence ensures your investment delivers maximum value through years of reliable, efficient operation.

Source: https://kahkaham.net/read-blog/139225