With the rise of electric vehicles, decarbonization, and demand for advanced lightweight structures, manufacturers are turning to smarter, more efficient joining solutions. At the forefront is self pierce riveting—a technology that’s changing how cars, planes, and various industrial products are assembled for strength, sustainability, and speed.

What Is Self Pierce Riveting (SPR)?

Self pierce riveting (SPR) is a mechanical fastening method developed for joining multiple layers of metal, especially where welding falls short. SPR uses a specially designed rivet to pierce and mechanically interlock sheets, without the need to pre-drill holes or apply heat. This results in a solid, vibration-resistant connection with minimal impact on the appearance of the workpiece.

Key Benefits for Modern Manufacturing

SPR offers a series of unique advantages:

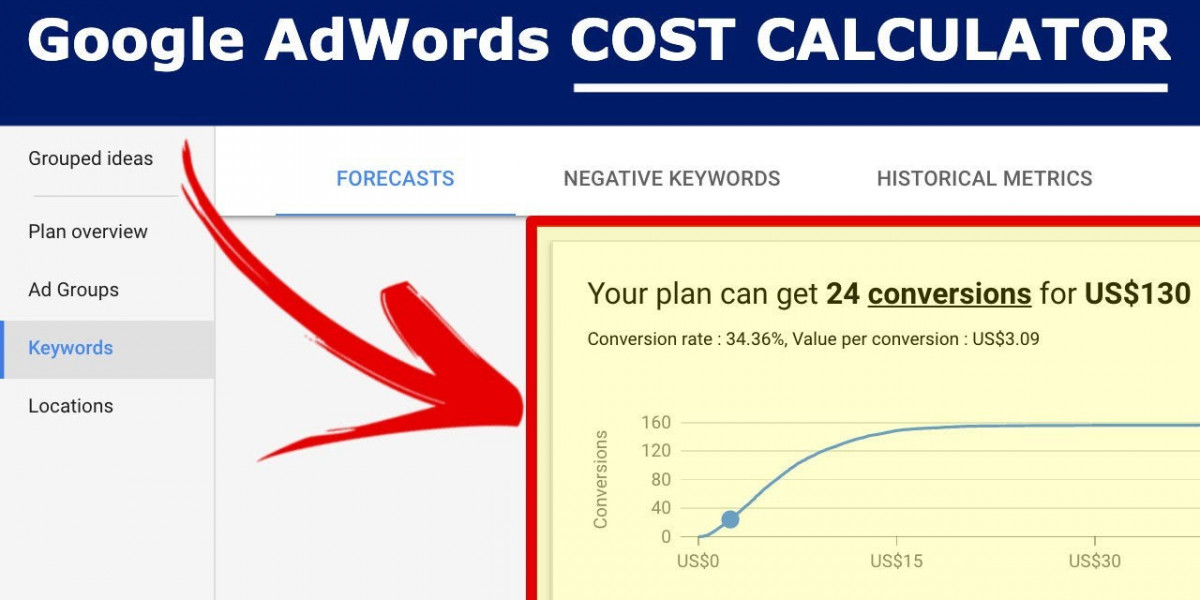

High-Speed Automation: Advanced SPR systems are engineered for fully automated production lines, boosting output for manufacturers of all sizes.

Cost-Efficiency: SPR machines offer low energy consumption, reduced maintenance, and minimal mold changes, cutting operating costs while maintaining productivity.

Eco-Friendly Production: Compliant with strict environmental guidelines, self pierce riveting reduces waste, fume, and overall energy use.

Precision for Complex Structures: Highly flexible and miniaturized SPR equipment can access hard-to-reach spots, making it ideal for intricate components and new material combinations used in modern vehicles.

Why Leading Industries Are Switching to SPR

With vehicle structures getting more complex and the widespread use of dissimilar and lightweight alloys, traditional joining techniques often fall short. SPR not only delivers high-strength, corrosion-resistant bonds but also supports online quality monitoring—providing real-time feedback to guarantee consistency and maintain the highest standards in production.

Investing in the Future with SPR Solutions

Forward-thinking manufacturers are already seeing the benefits in speed, quality, and efficiency by implementing self pierce riveting solutions. From flush installations to real-time quality control, the technology is pioneering a new era of sustainable manufacturing—ensuring every connection is robust, reliable, and ready for tomorrow’s challenges.