Introduction

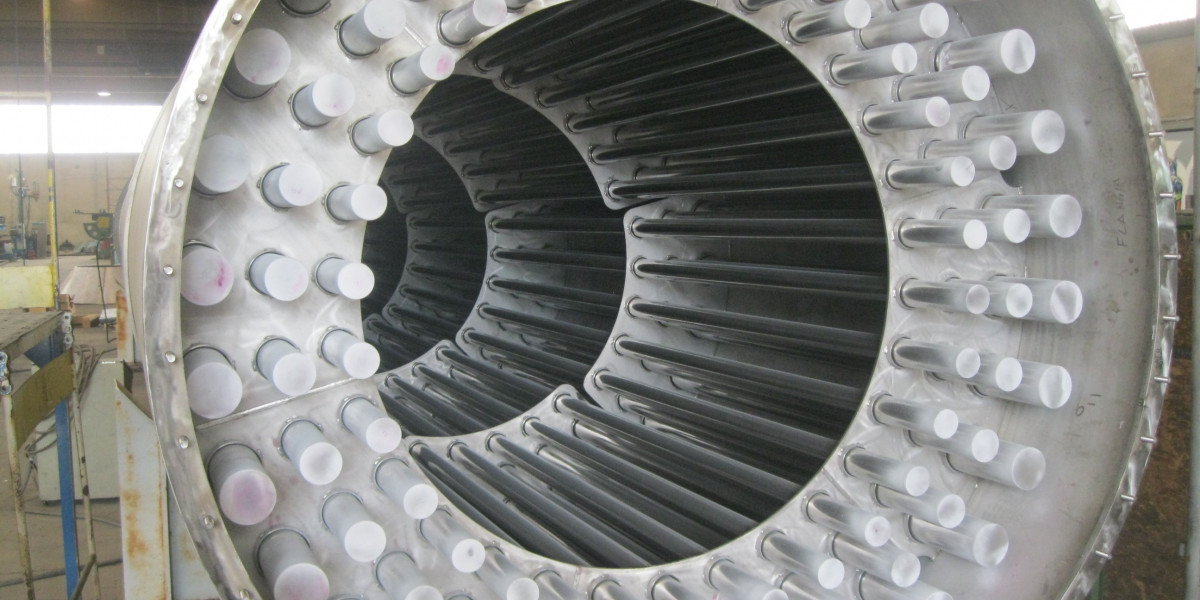

The rotary dryers market demand is witnessing unprecedented growth as global industries increasingly emphasize operational efficiency, sustainable production, and technological modernization. rotary dryers, known for their durability and versatility, are integral to a wide range of industrial applications including cement production, food processing, mining, fertilizers, and chemicals. Their ability to handle diverse material types and maintain uniform drying under variable conditions has made them a cornerstone of modern industrial drying operations.

The evolution of the rotary dryers market reflects the industrial world’s transition toward sustainable, intelligent, and energy-efficient systems. As manufacturers aim to meet global emission standards and reduce production costs, the demand for next-generation rotary dryers continues to rise. This article explores how innovation, sustainability, and automation are transforming the rotary dryers market and shaping the future of industrial heat processing.

Industrial Application Expansion and Versatility

The rotary dryers market demand is expanding across several industries due to the growing need for consistent, large-scale drying solutions. In the mining and mineral sector, rotary dryers are used for processing ores, limestone, and sand, ensuring materials achieve optimal moisture content before further treatment. Similarly, in the agricultural sector, they are critical in drying grains, biomass, and fertilizers to improve storage stability and quality.

The food and beverage industries are adopting rotary dryers for their ability to deliver uniform drying while preserving nutritional content and flavor integrity. In the chemical and pharmaceutical sectors, rotary dryers provide precise temperature control, ensuring product consistency and stability. The versatility of rotary dryers—capable of handling fine powders, granules, or large aggregates—continues to drive their adoption globally, reinforcing their indispensable role in industrial processing.

Technological Innovations and Digital Advancements

Technology remains the central force driving the rotary dryers market demand. The integration of automation and smart control systems has transformed rotary dryers from basic mechanical equipment into intelligent process tools. Modern dryers are equipped with IoT-enabled sensors, variable frequency drives, and real-time moisture analyzers that allow continuous process monitoring and optimization.

Artificial intelligence and machine learning are redefining operational efficiency by enabling predictive analytics for maintenance and performance management. These systems can anticipate component wear, optimize air flow and drum speed, and minimize downtime. Additionally, digital twin technology allows manufacturers to create virtual models of rotary dryers, simulating various operational scenarios to enhance design accuracy and production planning. This digital revolution is fueling the efficiency, reliability, and sustainability of the rotary dryers market.

Sustainability and Energy Efficiency as Core Growth Drivers

Sustainability has become a defining principle shaping rotary dryers market demand. As industries face stricter regulations on carbon emissions and energy consumption, manufacturers are redesigning rotary dryers to operate with maximum energy efficiency. New models incorporate waste heat recovery systems, regenerative burners, and advanced insulation technologies that reduce fuel requirements while maintaining high thermal output.

Hybrid rotary dryers, which combine traditional and renewable energy sources, are gaining traction as part of the global decarbonization movement. These dryers utilize solar, biomass, or electric heating options to minimize reliance on fossil fuels. Additionally, advancements in burner design and airflow optimization contribute to significant reductions in greenhouse gas emissions. By supporting sustainable industrial practices, the rotary dryers market continues to align with the global mission for cleaner, greener manufacturing processes.

Regional Market Expansion and Demand Patterns

The rotary dryers market is experiencing dynamic growth across multiple regions, each driven by unique industrial trends. North America and Europe are leading in technological sophistication, with industries investing in energy-efficient dryers that comply with environmental standards. These regions are focusing on retrofitting older systems with advanced monitoring and control technologies to extend operational lifespan and improve sustainability performance.

Asia-Pacific represents the fastest-growing region in the rotary dryers market due to rapid industrialization and infrastructure development. Countries such as China, India, Indonesia, and Vietnam are major consumers, driven by booming mining, cement, and agricultural industries. Meanwhile, Latin America and Africa are emerging as new growth frontiers, with increased investments in renewable energy and raw material processing industries creating opportunities for advanced rotary drying systems.

Integration of Smart Manufacturing and Automation

The convergence of Industry 4.0 technologies with industrial drying systems is revolutionizing the rotary dryers market. Smart manufacturing principles are now being integrated into drying operations, enabling seamless communication between rotary dryers and central control systems. Through IoT connectivity, rotary dryers can transmit operational data such as temperature, humidity, and energy usage in real time, allowing operators to make data-driven decisions.

Automation also enhances safety, reduces manual intervention, and increases process consistency. Manufacturers are leveraging cloud-based platforms to remotely monitor equipment performance across multiple facilities. This connectivity ensures that rotary dryers operate at peak efficiency, minimizing production downtime and extending equipment life. As automation and data analytics become standard in industrial ecosystems, the rotary dryers market is set to benefit from this technological evolution.

Challenges and Strategic Responses

Despite significant growth, the rotary dryers market faces certain challenges. High initial capital investment, maintenance complexity, and fluctuating energy prices can deter smaller businesses from adopting advanced drying solutions. Additionally, the need for skilled personnel to manage digitalized equipment remains a challenge in developing regions.

To address these issues, manufacturers are developing modular and scalable rotary dryers that can be customized according to production needs and budget constraints. Remote support, predictive maintenance tools, and user-friendly interfaces are simplifying operations and reducing training requirements. Financing solutions such as leasing and pay-per-use models are also making modern rotary dryers more accessible to emerging markets.

Emerging Opportunities in Renewable Integration

The integration of renewable energy into rotary dryers presents a significant opportunity for long-term market growth. Solar-assisted and biomass-fueled dryers are increasingly being adopted in agriculture, food, and biomass industries. These systems not only reduce energy costs but also contribute to emission reduction goals. Governments and corporations are supporting such technologies through subsidies and sustainability programs, boosting market adoption.

Electric rotary dryers, powered by renewable electricity, are also gaining popularity, particularly in regions aiming for carbon-neutral industrial processes. These innovations reflect the growing alignment between industrial development and global environmental sustainability objectives.

Future Outlook

The future of the rotary dryers market demand lies in continuous innovation, automation, and environmental responsibility. Manufacturers are focusing on developing fully digital, AI-driven dryers that can self-optimize based on real-time data. Advanced energy management systems will further enhance performance by dynamically balancing energy supply and demand.

The next decade will likely witness a surge in hybrid rotary dryers capable of operating on both conventional and renewable energy sources. As industries transition toward net-zero manufacturing, rotary dryers will remain at the forefront of sustainable process engineering. Their evolving design and integration capabilities will continue to influence how global industries manage thermal processing.

Conclusion

The rotary dryers market demand is at the intersection of industrial innovation, sustainability, and automation. From mining to agriculture, these systems are revolutionizing how industries process and preserve materials. Their growing integration with renewable energy and smart technologies highlights a clear shift toward eco-efficient and intelligent manufacturing practices. As companies worldwide invest in cleaner, smarter production systems, rotary dryers will continue to play an essential role in advancing industrial progress and environmental responsibility.