1. The Craft Behind the Clicks and Cuts

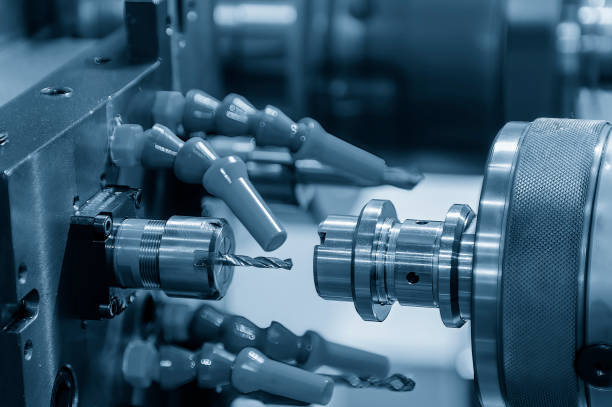

You ever watch a CNC machine work? It’s hypnotic. The way that tool head moves—tight, fast, like it knows exactly what it’s doing. And honestly, it does. Behind every polished part, every flawless thread, there’s precision you can’t fake. CNC precision turned components aren’t just parts—they’re proof that human know-how and machine accuracy can dance together.

In today’s world, everything’s built tighter, faster, smaller. That’s where CNC and Swiss machining walk in like old pros. They don’t mess around. No wasted movement. No guesswork. Just parts that fit, spin, and perform exactly how they should.

2. What “Precision Turned” Really Means

“Precision turned” sounds fancy, but it’s simple: you’re taking a raw bar of metal and turning it into something that actually matters. Something that fits a bigger system. Something that can’t afford to fail.

CNC precision turned components come out of high-speed, computer-controlled lathes that remove material down to fractions of a millimeter. We’re talking tolerances so tight you could sneeze wrong and mess it up. Aerospace parts, surgical tools, automotive fittings—they all depend on that level of control.

You can feel the difference in your hand. A properly turned part has a clean edge, a perfect surface, no wobble. It’s confidence, made of metal.

3. Swiss Machining: The Surgeon of Manufacturing

Swiss machining isn’t your everyday CNC setup. It’s the specialist. The surgeon. It came from the watchmaking world, where parts smaller than your fingernail had to be flawless. Over time, the technique scaled up, got smarter, and started running in industries that live and die by precision.

A Swiss machine holds the workpiece differently—supported close to the cut, so there’s no flex, no chatter. That means long, slender parts come out straight and clean. Think medical implants, aerospace connectors, defense components, fuel system fittings. You can’t afford distortion on those.

Swiss machining is like poetry in metal. It’s tight, clean, and brutally efficient.

4. Why CNC and Swiss Machining Go Hand in Hand

There’s a reason shops like Allied Technologies International, Inc. run both. CNC machining gives you flexibility—large parts, complex contours, fast programming changes. Swiss machining gives you microscopic precision for smaller runs or tight-tolerance work.

Put them together, and you’ve got a setup that can handle just about anything. Prototype? Production? Doesn’t matter. The parts roll out consistent every time.

Some folks say automation killed craftsmanship. Nah. It just evolved it. Machines don’t replace machinists—they amplify them. You still need someone who understands feeds, speeds, and when a cut “sounds wrong.” That’s where real skill shows up.

5. Materials That Make It Tough

Not every material plays nice. Stainless steel can warp. Titanium likes to chew up tools. Brass cuts like butter, but it’s soft. Plastics melt if you push too hard. That’s the reality of machining—you learn each metal’s attitude.

CNC precision turned components come from all of it—stainless, aluminum, titanium, copper, bronze, even engineering plastics. The trick is knowing what tools, coolants, and speeds make each one behave. That’s where experience walks in. You don’t guess. You listen, adjust, and get the finish right.

Swiss machines especially shine when you’re dealing with smaller diameters or exotic alloys. They don’t flinch. They just get it done.

6. Tolerance Isn’t Optional

Here’s a truth: “close enough” doesn’t cut it in precision machining. You’re either in spec or you’re scrap. CNC and Swiss machining thrive on exactness—measured, verified, documented.

You’ll see tolerances down to ±0.0002 inches. That’s about half the thickness of a human hair. You don’t hit that by luck. You hit it through process, calibration, and focus.

And when you nail it—when that inspection tool says you’re dead-on—it’s a quiet victory. Nobody claps, but you know you hit something that matters.

7. From Prototype to Production

Most projects start as a napkin sketch or CAD file that doesn’t look like much. Then the machine starts humming, the coolant sprays, chips fly—and suddenly, it’s real.

CNC and Swiss machining are perfect for that transition. You can make one prototype, test it, tweak the design, and then scale up without skipping a beat. Same code, same setup, just faster.

For startups, that’s gold. For big manufacturers, it’s reliability. Allied Technologies International, Inc. does both. They’ve got the machines, the team, and the patience to run jobs from “idea” to “inventory.”

8. Industries That Depend on Precision

Walk into a hospital, a plane, or a factory floor—you’re surrounded by machined parts. Surgical tools, valve fittings, sensor housings, turbine blades—all cut, turned, and finished to perfection.

Aerospace demands light, strong, flawless. Medical demands clean and exact. Defense demands reliability under stress. Every field leans on CNC precision turned components because there’s no other way to guarantee fit, function, and durability.

Swiss machining takes that even further, carving out micro components that keep everything working quietly in the background. It’s invisible engineering—until it fails. Then everyone notices.

9. The Human Side of Precision

Machines can’t feel pride. People can. The folks running those CNC lathes, setting up the Swiss machines—they’re craftsmen. Doesn’t matter how digital the shop gets, there’s still a pulse behind the parts.

You can teach someone G-code, but you can’t teach instinct. You either know when a tool’s dull by the sound, or you don’t. You either notice a 0.01mm deviation by sight, or you miss it.

That’s what separates good from great. Allied Technologies International, Inc. gets that. Their operators, programmers, inspectors—they’re not just button pushers. They’re builders.

10. Quality Is More Than Inspection

A lot of companies talk quality like it’s a slogan. But real shops live it. Every run gets checked. Every dimension logged. Every part tagged. It’s not paperwork—it’s accountability.

CNC precision turned components can’t afford shortcuts. One bad thread, one burr, and the whole assembly fails. That’s why you’ll see CMMs (coordinate measuring machines), optical comparators, micrometers stacked like candy in a precision shop.

Swiss machining? Same deal. It’s not just about getting close. It’s about knowing why you hit the numbers you did. Consistency is the badge of honor here.

11. Why Allied Technologies International, Inc. Stands Out

In a world full of machine shops, Allied Technologies International, Inc. keeps things simple: deliver better parts, faster, cleaner. They specialize in CNC precision turned components and advanced Swiss machining, handling everything from prototypes to full-scale production.

What sets them apart? They listen. They actually talk with engineers, not just take prints. They understand the pain of tight deadlines, of needing 100 parts yesterday and 1,000 tomorrow. They make it happen.

They’ve invested in top-tier machines, but they also kept that old-school shop mentality—measure twice, cut once, and never ship junk. That’s the difference between a vendor and a partner.

12. The Future: Precision Meets Automation

Here’s where it gets exciting. CNC and Swiss machining are evolving fast. Multi-axis setups, live tooling, real-time feedback—it’s all pushing tolerances even tighter. AI-driven monitoring, predictive maintenance, smart fixturing—it’s not science fiction anymore.

But here’s the kicker: no matter how advanced it gets, human skill still matters. Machines don’t troubleshoot weird vibrations or bad tool paths on instinct. People do.

That balance—technology guided by experience—is where Allied Technologies International, Inc. lives. Precision today, innovation tomorrow. That’s the game.

FAQs

Q1: What are CNC precision turned components?

They’re machined parts produced with extreme accuracy using computer-controlled lathes. These components serve industries like aerospace, defense, and medical where precision matters more than anything.

Q2: How does Swiss machining differ from CNC machining?

Swiss machining supports the workpiece closer to the cutting tool, allowing tighter tolerances on smaller, longer parts. It’s ideal for medical and aerospace components requiring micrometer accuracy.

Q3: Why are tight tolerances important in manufacturing?

Tight tolerances ensure parts fit and function perfectly, reducing failure rates, vibration, and wear. In precision engineering, “almost right” can mean total failure.

Q4: What materials can be used in Swiss machining?

Everything from stainless steel and titanium to brass, aluminum, and advanced plastics. Each needs different speeds, feeds, and coolant strategies.

Q5: How can CNC and Swiss machining help product development?

They bridge the gap between design and production—turning CAD concepts into physical parts fast, repeatably, and accurately.

The Bottom Line

Precision machining isn’t just a business. It’s a mindset. A mix of grit, math, and obsession with getting it right. CNC precision turned components and Swiss machining are how modern industry keeps its promises—tight, clean, and consistent.

When the job calls for zero compromise, call the people who get it. Visit Allied Technologies International, Inc to start.