The global 3D Printing Metal Market is poised for a remarkable transformation over the next decade. Valued at USD 6.9 billion in 2025, the market is projected to soar to USD 61.4 billion by 2035, expanding at an impressive compound annual growth rate (CAGR) of 24.5%, according to the latest research report, “3D Printing Metal Market Size and Share Forecast Outlook 2025 to 2035.”

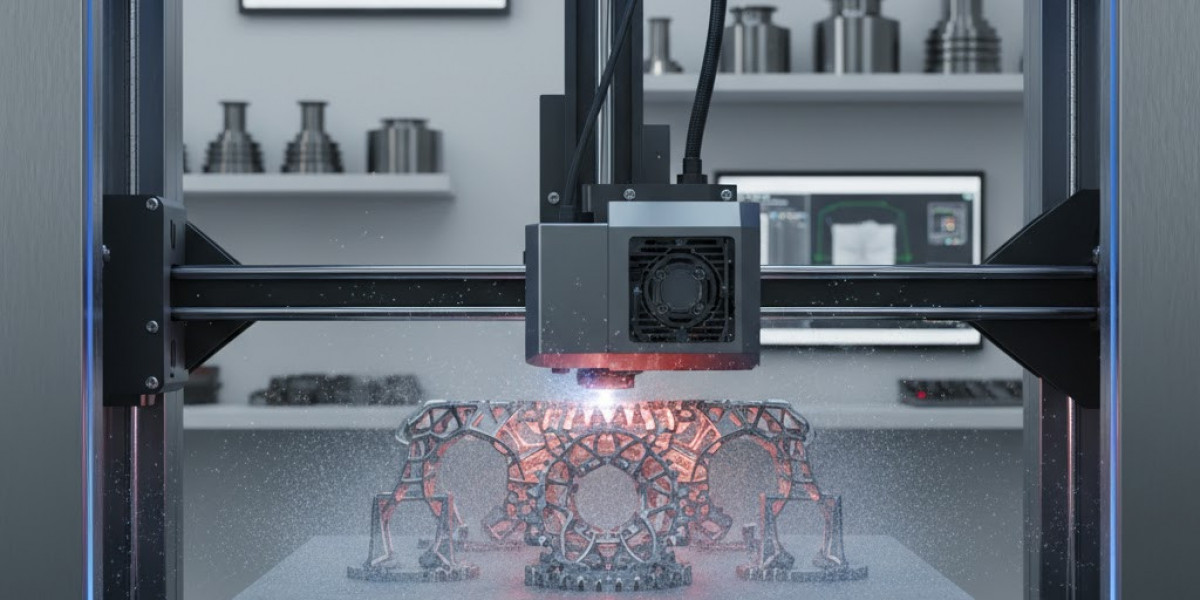

With industries rapidly shifting toward additive manufacturing to enhance efficiency, reduce waste, and achieve design flexibility, the 3D printing metal sector is witnessing exponential growth across aerospace, automotive, healthcare, and defense applications.

Rising Demand for Additive Manufacturing Driving Market Expansion

The surge in 3D metal printing adoption is being driven by its ability to deliver lightweight, durable, and high-strength components that conventional manufacturing techniques often cannot achieve. From aerospace engines and customized implants to precision automotive components, 3D printing metals enable intricate geometries and material optimization that redefine industrial production.

The technology’s role in reducing material waste and streamlining supply chains is transforming manufacturing economics. Moreover, the integration of artificial intelligence (AI) and machine learning (ML) for print optimization, predictive maintenance, and automated quality control is propelling next-generation production capabilities.

“Metal additive manufacturing has shifted from being a niche innovation to a mainstream industrial solution,” said a senior analyst at Future Market Insights. “With ongoing research in materials science and improved printing precision, manufacturers are now moving toward scalable, sustainable, and cost-effective 3D metal printing ecosystems.”

Segmental Overview: Key Insights from the 3D Printing Metal Market

- Aluminum Dominates the Metal Type Segment

The aluminum segment is expected to hold 21.4% of the total market share in 2025, establishing itself as the leading metal type. Aluminum’s combination of lightweight strength, corrosion resistance, and versatility makes it a preferred choice in aerospace, automotive, and electronics manufacturing.

Its ability to deliver high strength-to-weight ratios supports sustainability goals and enhances fuel efficiency in transportation applications. Moreover, continuous advancements in aluminum powder formulations for additive manufacturing are improving printability, performance, and affordability.

As new aluminum alloys optimized for 3D printing emerge, this segment is set to maintain robust growth through 2035.

- Powder Form Leads in Market Share

Among forms, the powder segment is anticipated to capture 63.7% of market revenue in 2025, driven by its dominance in precision manufacturing. Powder-based additive manufacturing provides exceptional layering accuracy, enabling high-performance part fabrication with complex geometries.

Industries such as aerospace, defense, and healthcare are increasingly favoring powder-based printing for mission-critical applications due to its superior material consistency and recyclability. The recyclability of unused powders also contributes to sustainability, aligning with global efforts to minimize waste.

Continuous innovations in atomization and post-processing technologies are enhancing powder flowability and particle uniformity—factors essential for achieving high-quality outputs and cost-effective mass production.

- Powder Bed Fusion Technology: The Market Cornerstone

The Powder Bed Fusion (PBF) segment is projected to hold a 36.9% revenue share in 2025, making it the most widely adopted technology in the 3D printing metal landscape. PBF’s precision, structural integrity, and ability to create intricate, high-strength parts make it indispensable for aerospace, medical, and industrial applications.

The technology’s flexibility to process multiple metal powders—such as aluminum, titanium, and stainless steel—extends its relevance across diverse industries.

While PBF systems require higher upfront investment, their long-term benefits—superior part performance, minimal material waste, and reduced lead times—reinforce their market leadership.

Regional Outlook: North America and Asia-Pacific Spearheading Growth

The 3D printing metal market is experiencing dynamic growth across key regions, with North America, Asia-Pacific, and Europe emerging as leading contributors.

- China is projected to post the highest CAGR at 33.1%, driven by government support for industrial digitization and rising aerospace and automotive manufacturing.

- India follows with a 30.6% CAGR, reflecting a growing focus on localized production and rapid adoption of additive technologies.

- Germany, France, and the UK continue to anchor Europe’s dominance in advanced manufacturing, while the United States, valued at USD 2.3 billion in 2025, is projected to reach USD 15.5 billion by 2035 with a 20.8% CAGR.

- Emerging markets such as Brazil and South Korea are also witnessing accelerated uptake as local manufacturers integrate metal 3D printing into precision engineering and prototyping workflows.

Collectively, the top three countries are expected to account for 50–55% of global market value by 2025, underscoring a geographically diverse yet rapidly consolidating industry.

A Market of Opportunities for Both Established and Emerging Players

- The 3D Printing Metal Market remains open and competitive, providing vast opportunities for established manufacturers and new entrants alike. While legacy players such as 3D Systems Inc., EOS GmbH, GE Additive, Renishaw PLC, and HP Inc. continue to push the boundaries of additive manufacturing with high-precision systems, a new generation of innovators is emerging.

- Companies like Desktop Metal, Markforged, Velo3D, Bright Laser Technologies (BLT), and Xact Metal are disrupting traditional production models by introducing compact, affordable, and scalable 3D metal printing solutions. These players are targeting small and mid-sized manufacturers, democratizing access to metal additive manufacturing technologies that were once limited to large industrial operations.

- Additionally, Materialise NV, Farsoon Technologies, and Meltio are advancing software integration, multi-metal capabilities, and hybrid manufacturing platforms—reshaping how design, engineering, and production converge in modern industries.

- This blend of technological innovation and competitive diversification is creating fertile ground for partnerships, R&D collaborations, and global expansion. As companies seek to expand their geographic footprint and technical capabilities, mergers, acquisitions, and joint ventures are expected to accelerate across the ecosystem.

Market Outlook: A Decade of Unprecedented Growth

- According to Future Market Insights, the 3D Printing Metal industry will continue its rapid trajectory through 2035. With ongoing breakthroughs in materials engineering, process automation, and design simulation, additive manufacturing is expected to account for a growing share of the global metal production landscape.

- Although currently representing just 0.1% of the global metal market, analysts forecast substantial 25–30 basis point gains in market share over the next decade, reflecting both technological maturity and expanding industrial acceptance.

- As the world moves toward smarter, cleaner, and more adaptive production systems, the 3D Printing Metal Market stands at the forefront of this revolution—bridging innovation, sustainability, and digital transformation in the era of Industry 4.0.

This Report Now at Just $5000 | Limited-Time Discount Offer! https://www.futuremarketinsights.com/reports/sample/rep-gb-2858

Checkout Now to Access Industry Insights: https://www.futuremarketinsights.com/checkout/2858

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.