In today’s electronics industry, precision and efficiency are key to producing high-performance devices. Printed Circuit Boards (PCBs) are the backbone of almost all electronic gadgets, and their quality directly impacts functionality. To achieve accuracy and speed in production, the pcb laser cutting machine has become an essential tool, allowing manufacturers to meet the growing demand for smaller, more complex circuit designs.

What Is a PCB Laser Cutting Machine?

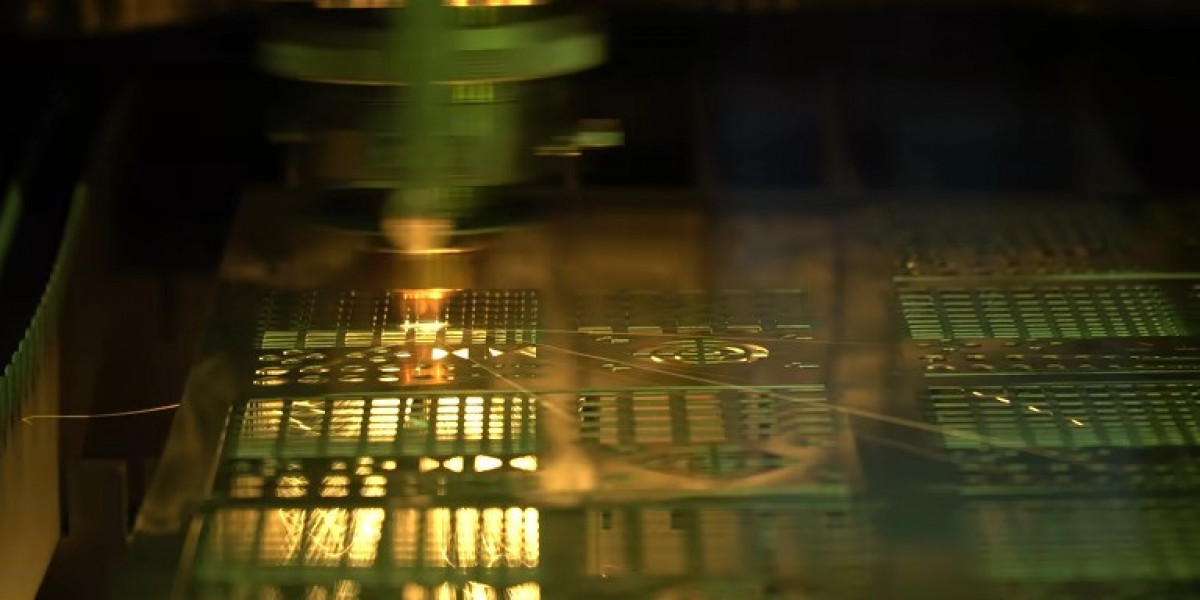

A pcb laser cutting machine uses a high-powered laser beam to cut, shape, or engrave circuit boards. Unlike traditional mechanical methods, laser cutting is non-contact, which reduces the risk of damage to delicate materials. The laser precisely removes material along a defined path, producing clean edges and minimizing microcracks that could compromise the board’s performance.

Modern machines integrate advanced software that guides the laser according to a digital design, ensuring consistency across both prototypes and large-scale production.

Advantages of Using Laser Cutting Technology

The adoption of a pcb laser cutting machine offers several advantages over conventional methods:

High Precision: Micron-level accuracy ensures even complex, high-density PCBs are manufactured correctly.

Non-Contact Processing: Reduces mechanical stress on fragile substrates.

Material Versatility: Capable of cutting FR4, polyimide, ceramics, and other PCB materials.

Efficiency: Automated systems significantly reduce production time.

Minimal Waste: Laser cutting produces smooth edges, minimizing material loss.

These benefits make laser cutting indispensable for industries requiring reliable and compact electronic components.

Industrial Applications

PCB laser cutting technology is widely used across various sectors:

Consumer Electronics: Ensures precise, compact circuit boards for smartphones, laptops, and wearables.

Medical Equipment: Produces high-precision PCBs for diagnostic and monitoring devices.

Automotive Electronics: Supports complex circuits in electric and autonomous vehicles.

Aerospace and Defense: Delivers high-reliability PCBs for critical systems.

In all of these applications, the pcb laser cutting machine allows manufacturers to meet stringent performance and quality standards.

How the Process Works

A typical pcb laser cutting machine includes a laser source, optical system, motion controller, and exhaust system. The laser source generates a highly concentrated beam that is focused by lenses onto the PCB surface. Motion controllers guide the laser along the exact path defined by the CAD/CAM design.

The exhaust system is essential for removing fumes and debris generated during cutting. This ensures a clean work environment and prevents contamination of the board’s surface.

Cost Efficiency and Environmental Impact

Laser cutting is more energy-efficient compared to mechanical methods, as it eliminates the need for consumable tools like drill bits and blades. Maintenance costs are lower, and the process generates less scrap material. By reducing material waste and energy consumption, the pcb laser cutting machine provides both economic and environmental advantages.

The Future of PCB Laser Cutting

The future promises even more advancements in pcb laser cutting machine technology. AI-based monitoring and automation will enhance accuracy and reduce human error. Hybrid systems combining laser cutting with additive manufacturing may streamline the production process further.

Manufacturers are increasingly adopting smart laser systems to stay competitive, producing smaller, faster, and more reliable electronic devices.

Conclusion

The pcb laser cutting machine has revolutionized PCB production, offering unmatched precision, speed, and reliability. From consumer electronics to aerospace applications, it ensures high-quality results while reducing waste and operational costs. As electronic devices continue to shrink and increase in complexity, laser cutting will remain an essential technology in modern PCB manufacturing.