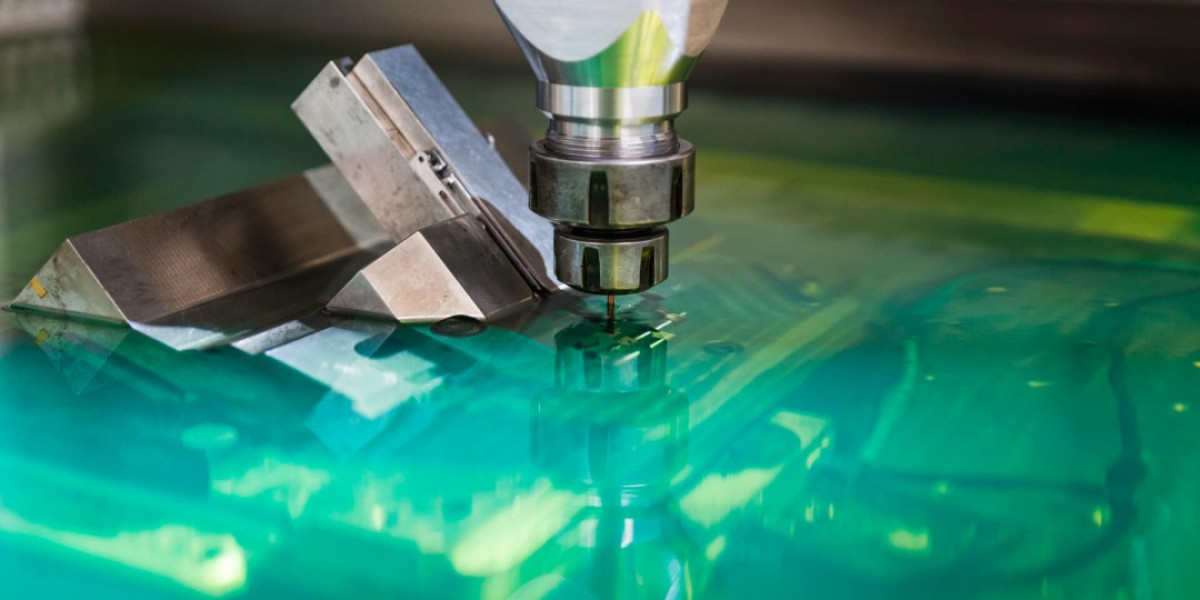

EDM fluids market continues to transform as industrial sectors push machining systems to handle higher loads, more complex geometries, and elevated thermal demands. The EDM fluids market thrives in environments where regulated heat dispersion directly influences machining accuracy, electrode life, and part reliability. As manufacturing embraces new alloys, tougher composites, and intricate multi-layer structures, the EDM fluids market rises to meet evolving expectations for stable thermal behavior, controlled dielectric strength, and consistent spark efficiency. These needs reinforce the EDM fluids market as a cornerstone of advanced precision manufacturing, reshaping both formulation strategy and industrial fluid engineering.

Rising Thermal Challenges in Modern Machining

The EDM fluids market is deeply influenced by the growing thermal challenges in high-density machining environments. As parts become more compact and embedded with fine surface features, heat accumulation during discharge becomes a critical concern. The EDM fluids market responds by delivering fluids capable of rapid heat absorption and stable thermal transfer, ensuring sparks remain consistent and erosion patterns stay uniform. Without reliable heat control, machining can lead to micro-cracking, distorted geometries, and inconsistent cavity formations.

In sectors manufacturing complex molds, die components, turbine elements, and medical-grade instruments, thermal stability significantly impacts part success. The EDM fluids market supports these industries with increasingly advanced formulations that handle fluctuating temperatures without rapid degradation. As machining cycles extend, stable thermal behavior allows manufacturers to maintain dimensional precision while reducing downtime caused by overheating or fluid breakdown. This priority places the EDM fluids market at the center of heat-sensitive industrial operations.

The Role of Fluid Chemistry in Thermal Performance

The chemical composition of dielectric fluids directly shapes the EDM fluids market’s role in thermal optimization. Traditional petroleum-based fluids once dominated, yet modern processes demand compositions engineered for elevated heat thresholds, reduced oxidation, and enhanced molecular stability. The EDM fluids market now emphasizes synthetic and semi-synthetic blends with structures that disperse heat more evenly, allowing machining to remain consistent even under prolonged high-energy discharge.

As industries adopt advanced materials requiring more intense spark discharges, fluid chemistry becomes integral to machining outcomes. The EDM fluids market supports these demands through improved viscosity stability, low vapor formation, and additives that maintain fluid clarity during heavy-use cycles. Because thermal distortion can compromise both machining speed and accuracy, the EDM fluids market continues improving formulations that sustain structural integrity while preventing fluid darkening, sludge buildup, or heat-induced volatility.

Precision Enhancement Through Thermal Balance

Precision machining relies on controlled spark formation, and the EDM fluids market plays a pivotal role in maintaining this balance. When thermal loads increase rapidly, spark gaps may fluctuate, leading to irregular erosion patterns and unpredictable material removal. The EDM fluids market mitigates this by offering dielectric solutions that stabilize the spark zone, reduce micro-variations, and maintain consistent dielectric strength even as temperatures rise.

This balance is essential when producing micro-level structures, thin-walled components, and fine cavities where minor thermal fluctuations can lead to deviations from design specifications. The EDM fluids market acknowledges these needs, reinforcing formulations that retain performance consistency during continuous sparking. This directly elevates the accuracy and repeatability of machining processes, allowing industries to achieve higher-quality results in shorter timelines.

Growing Influence of High-Load Applications

High-load EDM applications continue to expand, and with them, the demand for advanced solutions within the EDM fluids market. Heavy-duty machining, particularly in tool manufacturing, power-generation systems, aerospace engine components, and large automotive molds, places extreme stress on dielectric fluids. The EDM fluids market must respond by providing high-load compatible fluids that prevent thermal runaway, protect electrode integrity, and maintain uniform flow even when machining large surface areas.

As load intensities rise, fluid longevity becomes increasingly important. The EDM fluids market supports these environments by extending oxidation resistance, strengthening molecular cohesion, and reducing thermal instability. These improvements enable stable spark frequency across long machining cycles, directly contributing to reduced tool wear, improved part finish, and greater production efficiency.

Managing Thermal Degradation for Longer Fluid Life

Thermal degradation remains one of the critical issues influencing operational costs, making it a central concern within the EDM fluids market. With machining temperatures capable of rising sharply under high discharge frequency, fluids degrade at varying rates depending on composition and purity. The EDM fluids market addresses this by developing fluids that resist breakdown, maintain clarity, and reduce contamination buildup triggered by high heat.

Manufacturers increasingly prioritize options that extend service life, allowing longer periods between replacements and reducing filtration strain. This trend positions the EDM fluids market as an enabler of cost-efficient machining, supporting environments where high fluid turnover could otherwise disrupt production schedules. Next-generation formulations remain stable even in demanding thermal conditions, ensuring machining integrity throughout extended operations.

Thermal Effects on Electrode Wear and Productivity

Electrode wear is directly influenced by thermal conditions in machining, reinforcing the EDM fluids market’s importance in production stability. Excessive heat accelerates electrode erosion, ultimately reducing accuracy and requiring more frequent tool replacements. The EDM fluids market contributes solutions that help regulate heat distribution, slow electrode degradation, and create more controlled spark interactions.

These thermal-management benefits allow manufacturers to maintain higher productivity levels while achieving better surface finishes. As industries scale output, the EDM fluids market becomes vital for ensuring that electrodes remain sharp, consistent, and capable of precise energy discharge. Reduced wear translates into smoother machined surfaces, lower rework rates, and shorter cycle times, strengthening the long-term value of advanced dielectric formulations.

Advancements in Thermal Monitoring and Fluid Analytics

Digital innovations are reshaping the EDM fluids market as thermal monitoring systems integrate more deeply with machining platforms. Real-time fluid analytics allow manufacturers to track temperature spikes, viscosity changes, and dielectric strength fluctuations, enabling better decision-making during critical machining periods. The EDM fluids market aligns with this trend by developing fluids optimized for compatibility with these digital systems.

As Industry 4.0 systems expand, smart machining environments increasingly rely on fluids that communicate stable properties under varying thermal loads. The EDM fluids market benefits from these expectations, as producers refine formulas that deliver predictable performance feedback to automated controls. This evolution creates a forward-looking ecosystem where machining platforms, sensors, and dielectric fluids work cohesively.

Transition to Eco-Friendly Thermal Solutions

Sustainability is influencing product innovation within the EDM fluids market, driving interest in thermally stable fluids with lower environmental impact. Traditional fluids often struggled with volatility or produced harmful residues under intense heat. Modern formulations aim to offer both thermal durability and improved environmental profiles, supporting industries that seek cleaner machining without sacrificing performance.

The EDM fluids market now moves toward low-toxicity solutions, reduced fumes, and biodegradable formulations capable of withstanding high-energy discharge. Manufacturers adopting green machining strategies depend on these advanced fluids to maintain safe working environments while managing the thermal stresses of intensive EDM operations.

Future Path of Thermal-Focused Innovations

Thermal optimization will continue shaping the future of the EDM fluids market as industries pursue greater machining density, faster turnaround times, and more complex materials. Fluid technologies will evolve to integrate enhanced heat-dissipation properties, improved spark-zone stabilization, and more precise temperature management mechanisms. The EDM fluids market will also likely incorporate greater digital compatibility to support predictive degradation tracking and smarter maintenance cycles.

As machining equipment becomes faster and materials more sophisticated, the EDM fluids market will deepen its focus on thermal adaptability. Formulations designed to handle intensive discharge, sustained high-temperature cycles, and high-volume thermal stress will define the next era of dielectric advancements.

Conclusion

The EDM fluids market is fundamentally evolving to meet the rising thermal demands of modern machining environments. As industries depend on precise, stable, and thermally regulated machining systems.