In the realms of mining and construction, durability, safety, and precision are paramount. Whether you are erecting robust concrete structures or safeguarding tunnels in mining environments, you need trusted experts and high-quality products to guarantee long-term success. This is where concrete specialists and advanced products like mine guard systems come into play.

This comprehensive guide explores the critical role of concrete specialists in construction and mining projects and introduces the innovative Mine Guard Tunnel Guard system designed to enhance safety in challenging underground environments. We also point you towards reliable resources such as Altecrete, a leader in specialist concrete solutions and mining safety products.

For more information on expert concrete services and innovative mine guard solutions, visit:

Concrete specialists → https://altecrete.com/

Mine Guard Tunnel Guard → https://altecrete.com/tunnel-guard/

Why You Need Concrete Specialists for Mining and Construction

Concrete is one of the most widely used construction materials worldwide due to its strength, versatility, and cost-effectiveness. However, achieving the full benefits of concrete requires specialized knowledge in formulation, application, and curing processes. This is why engaging concrete specialists is critical, especially in demanding sectors like mining and heavy infrastructure.

What Do Concrete Specialists Do?

Concrete specialists are experts who understand the science and technicalities behind concrete production and application. Their roles include:

Designing mix formulations tailored to specific project needs, such as high-strength concrete or rapid-curing blends

Advising on concrete types for different environments, including underground tunnels and harsh weather conditions

Overseeing quality control during concrete mixing, pouring, and curing

Ensuring adherence to safety and structural standards

Troubleshooting problems like cracking, scaling, or premature deterioration

In mining, where underground infrastructure is exposed to extreme conditions, specialist concrete formulations can prevent costly failures and improve safety.

Why Concrete Quality is Vital in Mining and Tunnel Construction

Mining environments present a unique challenge for concrete use. Structures must withstand:

High mechanical stress from heavy machinery

Exposure to water and corrosive chemicals

Vibrations from blasting and drilling

Temperature fluctuations and humidity variations

Poor quality concrete can lead to cracks, water ingress, or even structural collapse, which compromises the safety of workers and equipment. This is why concrete specialists play an essential role in selecting materials that meet or exceed these requirements.

For reliable expertise in specialist concrete applications, you can explore industry-leading services here:

👉 https://altecrete.com/

Introducing Mine Guard: Advanced Protection for Mining Tunnels

While concrete provides the essential structural base, additional protective systems are needed in mining tunnels to ensure long-term safety. Enter the Mine Guard Tunnel Guard system, designed specifically for safeguarding underground tunnels from hazards like rock falls, debris, and structural weakening.

What is Mine Guard?

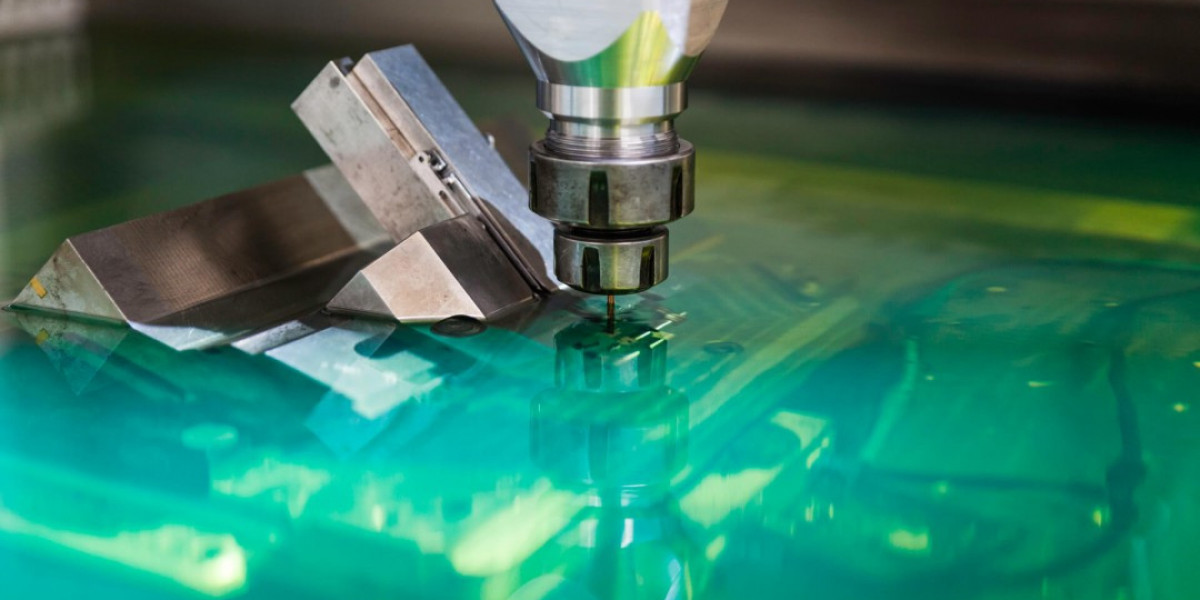

Mine Guard is a heavy-duty, durable steel mesh system engineered to support tunnel walls and ceilings in mining operations. It acts as a physical barrier, preventing loose rock and other material from falling and injuring personnel or damaging equipment.

The product is well-regarded for its strength, ease of installation, and adaptability to different tunnel sizes and shapes.

Discover more about this innovative product and how it can enhance your mining safety protocols here:

👉 https://altecrete.com/tunnel-guard/

Benefits of Using Mine Guard Tunnel Guard

1. Enhanced Worker Safety

The primary purpose of Mine Guard is to protect mine workers by preventing rock falls and debris from causing accidents. This significantly reduces downtime and injury risks.

2. Improved Tunnel Stability

By reinforcing tunnel walls, Mine Guard reduces deterioration caused by natural rock fracturing and mining operations, extending the lifespan of your tunnels.

3. Cost-Effective Solution

Investing in preventive protection like Mine Guard reduces costly repairs, lost production time, and liability expenses in the long run.

4. Quick and Easy Installation

The modular design of Mine Guard allows for fast deployment even in confined or complex tunnel geometries.

5. Compliance with Mining Safety Standards

Mine Guard meets international safety standards, giving mining operators peace of mind regarding regulatory compliance.

How Concrete Specialists and Mine Guard Work Together

Concrete specialists and Mine Guard systems are complementary in mining and tunnel construction projects:

Concrete specialists formulate and apply concrete that forms the structural backbone of tunnels and shafts, ensuring durability and resistance to the mining environment.

Mine Guard systems provide a secondary protective layer, securing the tunnels against rockfalls and loose material that concrete alone may not address.

By integrating expert concrete solutions with Mine Guard, mining companies can achieve safer, longer-lasting tunnel infrastructure.

Key Considerations When Choosing Concrete Specialists and Mine Guard Products

For Concrete Specialists:

Experience with Mining Projects: Choose specialists familiar with the unique demands of underground mining.

Technical Expertise: They should provide detailed mix designs and support quality assurance processes.

Material Quality: Ensure they source high-grade cement, aggregates, and additives tailored to harsh environments.

For Mine Guard Systems:

Customization: The system should be adaptable to different tunnel shapes and sizes.

Material Strength: Confirm the mesh meets or exceeds local mining safety regulations.

Installation Support: Look for suppliers that offer technical guidance and training during installation.

Altecrete stands out as a provider offering both specialized concrete solutions and top-quality Mine Guard products, delivering a full-service package. Visit their website for more information:

👉 https://altecrete.com/

Industry Applications of Concrete Specialists and Mine Guard

1. Mining Operations

Tunnel lining

Shaft reinforcement

Ventilation structures

2. Civil Engineering Projects

Bridge piers and abutments

Underground metro and railway tunnels

Water and sewage infrastructure

3. Industrial Facilities

Structural supports in heavy manufacturing plants

Safety barriers and containment zones

The combined expertise of concrete specialists and Mine Guard solutions ensures projects meet structural and safety demands across these sectors.

Why Choose Altecrete for Your Concrete and Mine Guard Needs?

Altecrete has established itself as a trusted leader in specialist concrete and mining safety products. Here’s why:

Industry Expertise: Years of experience working with mining companies and civil contractors

Comprehensive Product Range: From tailor-made concrete mixes to advanced Mine Guard solutions

Technical Support: Expert advice, project consultations, and onsite assistance

Quality Assurance: Commitment to premium materials and rigorous testing standards

For detailed product information and to connect with their team, explore:

Concrete Specialists → https://altecrete.com/

Mine Guard Tunnel Guard → https://altecrete.com/tunnel-guard/

Conclusion

Mining and construction projects demand high standards of safety, durability, and efficiency. Concrete specialists bring expert knowledge that ensures structural integrity through optimal mix design and application techniques. Meanwhile, innovative products like Mine Guard Tunnel Guard offer vital protection in underground mining environments, enhancing safety and reducing maintenance costs.

Together, these solutions address both the foundational and protective needs of mining tunnels and heavy infrastructure. Partnering with trusted providers such as Altecrete ensures your projects benefit from cutting-edge technology and expert support.

For dependable concrete expertise and advanced mine guard solutions, visit:

Frequently Asked Questions (FAQ)

1. What services do concrete specialists provide for mining projects?

Concrete specialists design and oversee concrete formulations tailored for mining environments, ensuring durability against harsh conditions and compliance with safety standards.

2. How does Mine Guard improve tunnel safety?

Mine Guard provides a strong steel mesh barrier inside tunnels to prevent rock falls and debris from endangering workers or damaging equipment.

3. Can Mine Guard be installed in existing tunnels?

Yes, Mine Guard’s modular design allows for retrofitting into existing tunnels to enhance safety without major reconstruction.

4. What makes Altecrete a reliable supplier for these products?

Altecrete offers specialized expertise, quality products, comprehensive technical support, and tailored solutions specifically for mining and construction industries.

5. How do I select the right concrete mix for my mining project?

Work with concrete specialists who assess environmental factors, load requirements, and chemical exposure to design a mix that ensures longevity and safety.

6. Are Mine Guard systems compliant with international mining safety standards?

Yes, Mine Guard meets or exceeds industry regulations for mining safety and structural support, providing reliable protection in underground tunnels.