In today’s fast-moving manufacturing landscape, every business relies on precision, reliability, and efficiency to stay competitive. At the heart of successful plastic production lies the Custom Injection Mold—an engineered tool that determines the quality, performance, and consistency of each produced part. Whether a company is creating automotive components, electronics, medical devices, custom toys, packaging items, or industrial equipment, the choice of a custom injection mold directly influences product accuracy, durability, production cost, and manufacturing speed. As industries evolve, the importance of working with a trusted and technologically advanced injection mold factory continues to grow.

What Makes a Custom Injection Mold Essential?

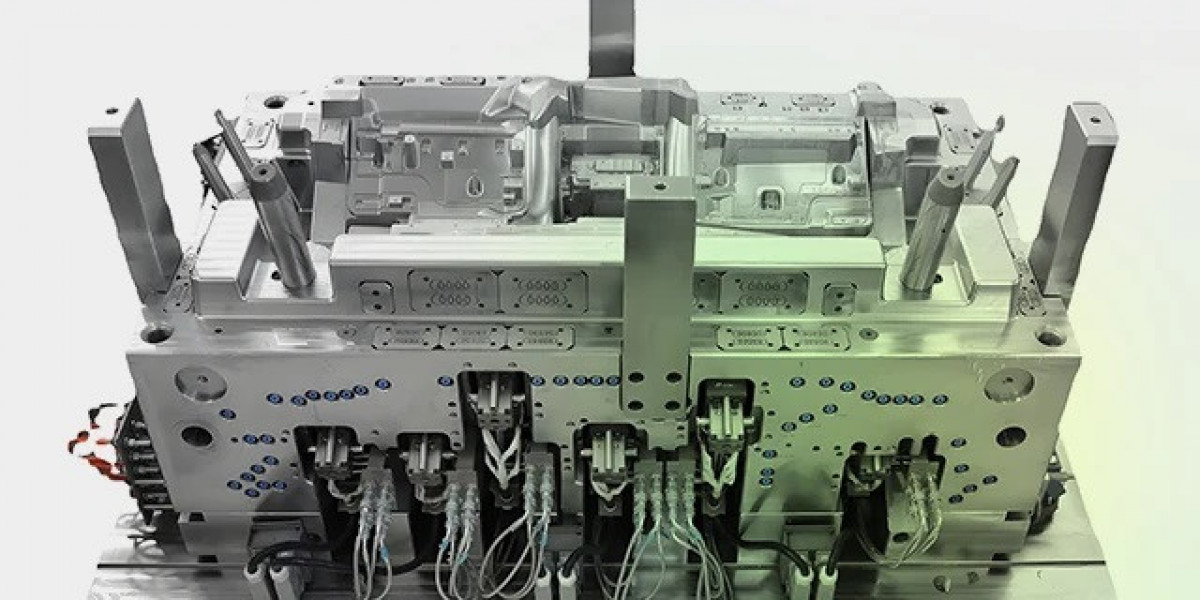

A custom injection mold is designed specifically for one product, following exact measurements, material properties, structural elements, and aesthetic goals. Unlike standard molds, it delivers unmatched accuracy and uniformity, making it ideal for mass production. By injecting molten plastic into the mold cavity, manufacturers can produce thousands or millions of identical parts. This accuracy reduces defects, eliminates waste, and ensures consistent dimensions—crucial for sectors where even small errors can compromise performance. Companies trust custom injection molds because they support complex geometries, unique textures, and precise engineering details that other manufacturing methods cannot achieve.

Why Working With a Professional Injection Mold Factory Matters

To fully benefit from custom molding, partnering with an experienced injection mold factory is essential. Professional factories use advanced engineering software, CAD/CAM systems, and mold-flow analysis tools to design molds with maximum efficiency. Their expert teams detect potential issues early, optimize mold structures, and simulate material behavior to avoid common production problems such as uneven filling or shrinkage.

High-level factories use precision machinery—CNC machining centers, EDM systems, high-speed milling equipment, and advanced polishing tools—to create molds that meet the highest global manufacturing standards. Their deep material knowledge, including shrinkage rates, heat tolerance, and chemical compatibility, ensures that every mold delivers long-term durability and exceptional performance.

Key Benefits of Choosing a Reliable Injection Mold Factory

Working with a reputable injection mold factory provides numerous advantages. These factories shorten lead times, helping businesses launch products faster without sacrificing quality. A high-quality custom injection mold reduces long-term maintenance costs and supports millions of production cycles, lowering the cost per part while improving production efficiency. Professional factories also offer after-sales support such as mold repairs, polishing, part replacement, and engineering upgrades, ensuring the mold stays in excellent working condition throughout its lifespan. This combination of technology, precision, and long-term service makes a reliable injection mold factory one of the most valuable partners for any manufacturing business.

How Custom Injection Molds Improve Manufacturing Efficiency

Custom injection molds allow for detailed textures, precise geometries, and complex internal structures that would be impossible with traditional methods. Injection molding remains one of the fastest manufacturing techniques, capable of producing large quantities of identical pieces in minutes. This repeatability guarantees consistent quality, while the process itself generates minimal scrap material. Reduced waste means lower costs and more sustainable production. Although custom molds require an initial investment, the long-term savings, reduced defects, and high-speed production make them the most economical option for large-scale operations.

Choosing the Right Injection Mold Factory for Your Project

The success of any manufacturing operation often depends on selecting the right injection mold factory. Businesses should consider a factory’s technical expertise, industry experience, and ability to execute complex projects such as multi-cavity molds, hot runner systems, insert molding, or over-molding. Factories with advanced machinery, strict quality control processes, and trial-run procedures provide greater reliability. Transparent communication, clear pricing, and strong after-sales support further guarantee smooth project execution from early design stages to mass production.

Conclusion: High-Quality Custom Injection Molds Start With the Right Factory

Investing in a high-quality custom injection mold is one of the most effective ways to elevate product quality and manufacturing efficiency. Choosing a technologically advanced and professionally experienced Injection Mold Factory ensures superior engineering, faster production cycles, reduced defects, and long-term cost savings. Whether launching a new product or upgrading current manufacturing systems, partnering with the right injection mold factory guarantees consistent performance, precise results, and improved productivity. For any business aiming to succeed in today’s competitive industrial environment, the right custom injection mold solution is the key to long-term growth and manufacturing excellence.

#custom injection mold , #injection mold factory