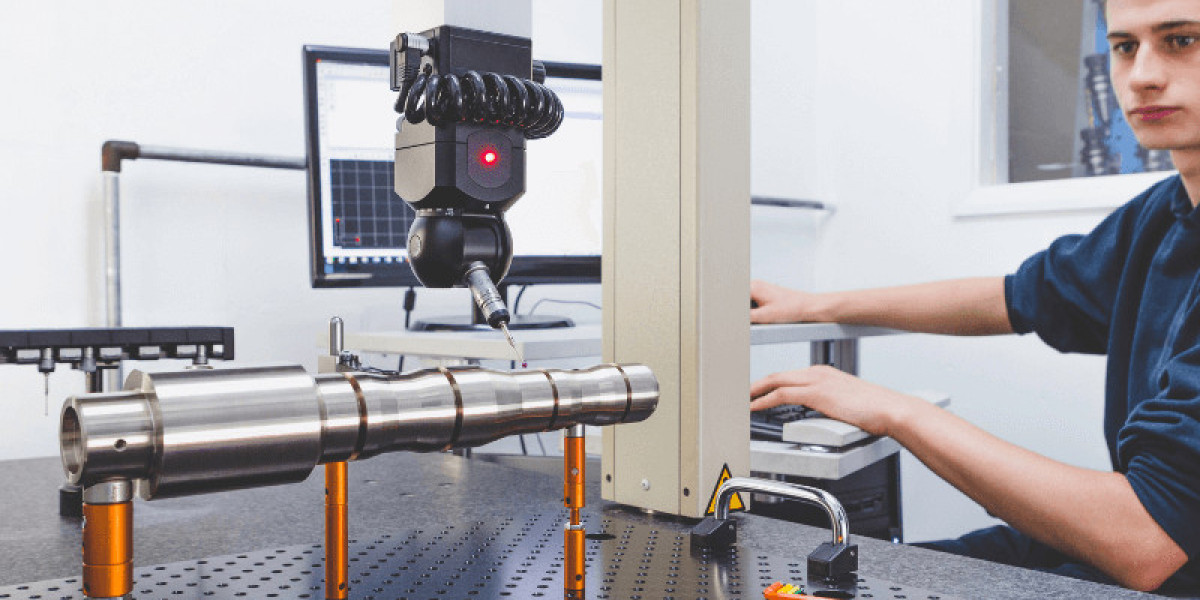

Coordinate Measuring Machines (CMM) Manufacturer in California: Helmel Engineering Products, Inc.

In today’s precision-driven manufacturing world, quality control is no longer simply an added value it is an absolute necessity. Industries such as aerospace, automotive, medical devices, electronics, and defense rely on extremely tight tolerances and consistent dimensional accuracy. At the center of this quality assurance ecosystem are Coordinate Measuring Machines (CMMs), the backbone of modern inspection and metrology labs. Among the companies shaping the CMM landscape in the United States, Helmel Engineering Products, Inc. stands out as one of California’s most respected names in precision measurement.

For decades, Helmel Engineering has built a reputation rooted in reliability, craftsmanship, and engineering excellence. This blog explores why Helmel Engineering Products, Inc. has become a trusted CMM manufacturer in California and how its solutions help companies streamline quality processes, reduce scrap, and achieve repeatable inspection results.

A Legacy of American Manufacturing and Engineering Precision

Helmel Engineering Products, Inc. was founded with a clear vision: to provide durable, accurate, and uncomplicated coordinate measuring machines designed for long-term use. Unlike many equipment manufacturers that rely heavily on foreign components or outsource machine structures, Helmel has maintained a strong commitment to American manufacturing principles.

Their philosophy centers on three pillars:

1. Mechanical Integrity

Helmel CMMs are known for their sturdy, granite-based structures and precision mechanical bearings. This design ensures long-term stability, minimal wear, and dependable accuracy even in demanding shop-floor environments.

2. Long-Term Measurement Accuracy

Rather than focusing solely on software-driven compensation often used to mask mechanical shortcomings Helmel emphasizes precision-built hardware. This means their machines offer real, physical accuracy first, with software compensation used only as an enhancement rather than the primary accuracy mechanism.

3. Lifetime Value

Many CMMs on the market are built with lightweight materials or rely heavily on complex electronics that degrade over time. In contrast, Helmel machines are designed for longevity, making them a cost-effective investment for companies seeking a machine that will last decades rather than years.

Made in America, Trusted Worldwide

California’s manufacturing scene especially in aerospace, electronics, and medical technologies has long valued precision and performance. Helmel Engineering’s CMMs align perfectly with these values. Although the company serves customers across the United States and globally, California remains one of its strongest markets due to the state's high concentration of quality-sensitive industries.

Manufacturers across California rely on Helmel CMMs to maintain compliance with:

- AS9100 aerospace standards

- ISO 9001 quality systems

- FDA-regulated medical device requirements

- Automotive PPAP and APQP processes

- Military and defense inspection protocols

Because Helmel machines are built for rugged reliability, they integrate well into both lab environments and production-floor settings something that California manufacturers value given the high mix of precision machining and high-volume production.

A Complete Line of Coordinate Measuring Machines

Helmel Engineering offers a diverse portfolio of CMM systems tailored to the needs of small machine shops, large-scale manufacturers, R&D labs, and automated inspection environments. Their product line includes:

Manual CMMs

Ideal for small shops, prototyping, or applications where inspectors require a hands-on approach. Manual CMMs are cost-effective, easy to maintain, and extremely durable.

Digi-CMM Systems

A Helmel innovation that bridges the gap between manual inspection and fully automated measurement. Digi-CMMs offer digital readouts and intuitive interfaces while retaining the tactile control of manual systems.

Automatic and CNC CMMs

For high-throughput inspection, Helmel’s automated machines deliver repeatability and speed. These systems integrate easily with modern metrology software, SPC reporting tools, and CAD-based inspection workflows.

Shop-Floor CMMs

Built to withstand temperature variations, vibration, dust, and other challenging conditions, Helmel’s rugged CMMs allow manufacturers to bring quality control straight to the point of production reducing bottlenecks and improving cycle time.

Custom and Special-Purpose CMM Solutions

Helmel also designs specialized systems for customer-specific applications, including unique probes, fixtures, and custom measurement envelopes.

Metrology Software: The Heart of Modern Inspection

CMM performance is not defined by mechanics alone. Software plays a pivotal role in capturing, analyzing, and reporting measurement data. Helmel Engineering pairs its machines with robust metrology software solutions that support:

- CAD model import and measurement

- Geometric dimensioning and tolerancing (GD&T)

- Automated feature recognition

- SPC reporting and data logging

- Customizable measurement routines

This combination of precision hardware and powerful software ensures that every Helmel system is capable of handling both routine inspections and complex geometric measurements with ease.

Why California Manufacturers Choose Helmel Engineering

1. Unmatched Durability

Helmel machines are built to last. Many customers report decades of reliable service with minimal maintenance something extremely rare in modern metrology equipment.

2. User-Friendly Operation

Whether manual or automated, Helmel CMMs are designed with simplicity in mind. Operators can learn the system quickly without the steep learning curve often associated with other brands.

3. Competitive Pricing and Low Ownership Cost

Because the machines do not depend on proprietary controllers or expensive consumables, long-term ownership costs remain low.

4. Exceptional Customer Support

Helmel is known for responsive support, parts availability, and knowledgeable technicians an advantage when uptime is critical.

5. Designed for Real Manufacturing Environments

Helmel CMMs thrive where other machines struggle on the production floor, in facilities with temperature fluctuations, and in shops with heavy machining activity.

Driving Quality Into the Future

As California continues to lead the nation in advanced manufacturing, the demand for repeatable, reliable, and accurate measurement technology will only grow. Companies like Helmel Engineering Products, Inc. play a vital role in supporting this ecosystem by delivering American-made CMMs that meet the highest standards of craftsmanship and precision.

Whether a business is inspecting aerospace components, verifying medical device tolerances, or ensuring the accuracy of high-precision machined parts, Helmel’s coordinate measuring machines offer a proven path to improved quality, reduced scrap, and increased confidence in every measurement.

Business name : Helmel Engineering Products, Inc.

Phone number : 716-297-8644

Website : https://helmel.com/

Address : 6520 Lockport Road, Niagara Falls, NY 14305