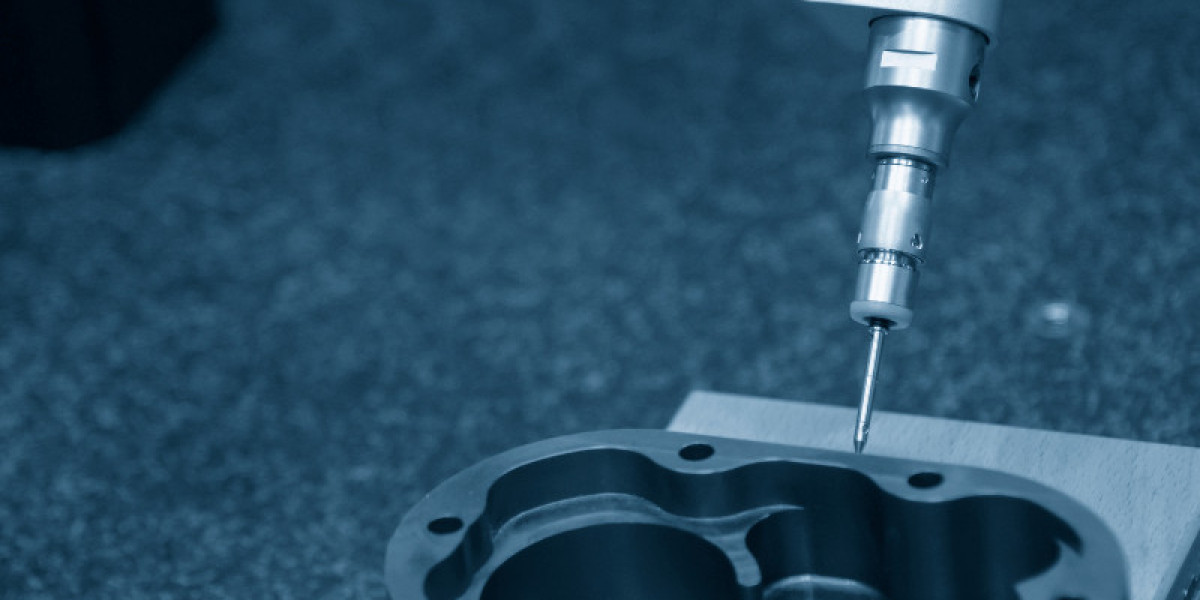

Coordinate Measuring Machines (CMM) Manufacturer in Vermont

Vermont’s manufacturing industry continues to expand, driven by precision machining, aerospace suppliers, medical manufacturing, electronics production, and advanced fabrication. With this expansion comes a growing need for precision measurement technology that delivers accuracy, consistency, and reliability. When it comes to dependable Coordinate Measuring Machines (CMMs), many Vermont manufacturers turn to Helmel Engineering Products, Inc., an American company known for engineering robust, long-lasting, and highly accurate CMM solutions.

For more than 50 years, Helmel Engineering has earned its reputation as a trusted metrology equipment manufacturer focused on mechanical integrity, durability, and ease of use. Unlike CMMs that depend heavily on compensation software to make up for structural weaknesses, Helmel builds its machines on strong mechanical foundations ensuring accuracy that lasts for decades. Vermont’s growing industrial sector benefits from this reliability, especially as quality requirements and tight tolerances continue to become more demanding.

The Rising Need for Precision Measurement in Vermont

Across Vermont’s high-tech and manufacturing sectors, accuracy plays a critical role in production efficiency, regulatory compliance, and product quality. CMMs help manufacturers verify dimensions, validate complex geometries, and maintain strict tolerances demanded by today’s engineering standards.

Local industries require CMMs capable of:

- Maintaining repeatability in fluctuating shop-floor environments

- Measuring complex components with precision

- Integrating with CAD models and advanced inspection routines

- Providing reliable performance with minimal maintenance

- Delivering long-term stability and accuracy

For Vermont operations ranging from clean-room medical production to rugged machine shop environments, Helmel’s CMMs meet these expectations with unmatched mechanical strength.

As companies in the state continue to evaluate metrology solutions, many begin their search by reviewing equipment categories, making “Explore Our Full Line of Coordinate Measuring Machines” a natural entry point for manufacturers seeking the right CMM model for their workflow.

Why Vermont Manufacturers Prefer Helmel CMMs

1. American-Made Quality

Helmel CMMs are designed, engineered, and manufactured in the United States. For Vermont companies, this means faster support, reliable parts availability, and consistent product quality. U.S.-based manufacturing ensures shorter wait times and dependable customer service.

2. Superior Mechanical Construction

Helmel machines feature:

- Granite bases and columns

- Precision-machined guideways

- Robust mechanical bearings

- Stable frames engineered to resist distortion

These design choices help maintain accuracy over long periods, even in real-world shop-floor conditions.

3. Straightforward, Powerful Software

Helmel’s GEOMET software is preferred for its clarity and capability. Users can easily perform complex GD&T measurements, automate inspection routines, and generate comprehensive reports. The software is intuitive for new operators yet powerful enough for advanced applications.

At this stage in the inspection process, many Vermont manufacturers transition from manual measurements to full automation, which is why the inclusion “Learn More About Helmel’s CNC Coordinate Measuring Machines” helps guide users toward solutions that boost productivity and repeatability.

Industries in Vermont That Benefit from Helmel CMMs

Aerospace & Defense

Vermont’s aerospace suppliers require tools capable of verifying strict dimensional tolerances. Helmel CMMs ensure compliance with demanding industry standards for machined parts, housings, and critical components.

Medical Device Manufacturing

Precision is essential in medical device production. Helmel systems deliver accurate measurements needed for regulatory compliance and high-quality manufacturing.

Electronics & Micro-Component Manufacturing

From circuit housings to micro-machined parts, Vermont’s electronics industry demands reliable, repeatable accuracy something Helmel CMMs consistently provide.

Precision Machining

Job shops across the state rely on Helmel CMMs for daily quality control, inspection of prototypes, and verification of production runs. Their rugged build makes them ideal for shop-floor use.

Research & Education

Technical colleges and engineering programs choose Helmel CMMs for training future machinists and engineers due to their durability and user-friendly operation.

Types of CMMs Available from Helmel Engineering

Manual CMMs

Ideal for small shops, prototype verification, and low-volume inspection tasks. These systems provide excellent accuracy without complex programming.

CNC Automated CMMs

Designed for high-throughput workflows. CNC CMMs execute automated routines that improve efficiency and ensure consistent measurement results.

Shop-Floor CMMs

These systems are built to handle vibration, temperature fluctuation, and contaminants commonly found in active production environments.

Custom Metrology Systems

Helmel offers custom fixtures, specialized probing solutions, and tailored systems for unique part geometries or specialized applications.

What Sets Helmel Apart?

Longevity

Helmel machines are known to operate reliably for decades. Their mechanical precision reduces the need for major service and minimizes long-term costs.

Cost-Effective Ownership

By eliminating delicate systems like air bearings and minimizing the need for constant calibration, Helmel CMMs keep operating costs low.

Direct Access to Technical Support

Helmel provides reliable, U.S.-based support. Vermont manufacturers appreciate immediate access to knowledgeable technicians and engineers.

When Vermont businesses are ready to discuss a measurement challenge or request a quote, “Contact Helmel Engineering for CMM Solutions in Vermont” becomes a critical connection point between manufacturers and Helmel’s technical experts.

Choosing the Right CMM for Your Vermont Operation

Selecting the right CMM involves understanding your workflow, environment, parts, and quality requirements. Vermont businesses should consider:

- Size and complexity of the parts to be measured

- Required tolerances

- Report generation needs

- Shop-floor vs. lab environment

- Desired level of automation

- Future scalability

Helmel’s experts can help evaluate these factors to match your operation with the ideal CMM model whether you need a simple manual system or a high-speed CNC inspection platform.

Final Thoughts

Vermont’s advanced manufacturing sector demands reliable, accurate, and long-lasting metrology solutions. As a trusted American manufacturer, Helmel Engineering Products, Inc. delivers CMMs designed for real-world performance. Their machines support aerospace suppliers, medical device manufacturers, precision machine shops, electronics producers, and educational institutions across the state.

If your Vermont facility aims to improve quality control, streamline inspection, and enhance measurement reliability, Helmel’s rugged and precision-built CMMs are a proven solution. With engineering focused on mechanical integrity and long-term value, Helmel remains one of the most dependable CMM manufacturers serving Vermont today.

Business name : Helmel Engineering Products, Inc.

Phone number : 716-297-8644

Website : https://helmel.com/

Address : 6520 Lockport Road, Niagara Falls, NY 14305