Coordinate Measuring Machines (CMM) Manufacturer in Maine

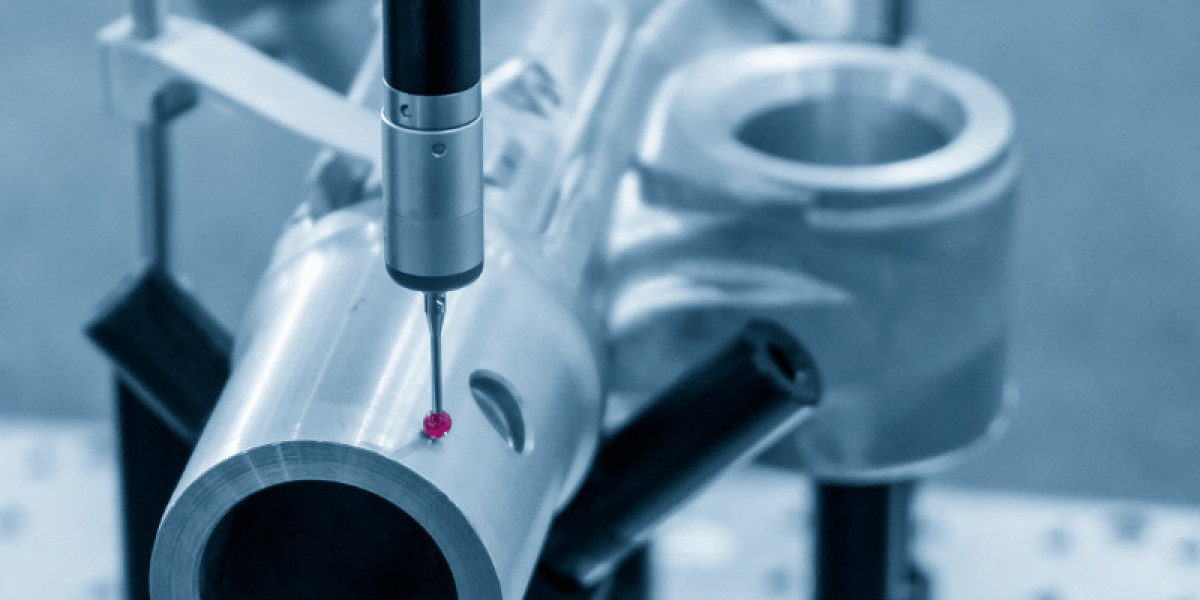

Maine’s manufacturing landscape continues to expand, with strong activity in aerospace, marine engineering, defense, medical manufacturing, precision machining, and advanced fabrication. As product design evolves and demand for tighter tolerances increases, Maine companies require reliable inspection systems that support accuracy, consistency, and quality control. For many of these manufacturers, Helmel Engineering Products, Inc. is the trusted source for durable, American-made Coordinate Measuring Machines (CMMs) that deliver dependable performance year after year.

With more than five decades of experience, Helmel Engineering has established itself as a leader in metrology solutions built on mechanical strength and long-term stability. While many modern CMMs rely heavily on software corrections to compensate for structural limitations, Helmel prioritizes true mechanical accuracy, resulting in machines that maintain precision even in shop-floor conditions. For manufacturers across Maine from Portland and Bangor to Lewiston and Auburn this reliability provides confidence in every measurement.

Why Precision Measurement Is Critical for Maine Manufacturers

Maine’s industrial sectors require CMMs capable of performing consistently despite environmental changes, varying workloads, and complex part geometries. Whether businesses are producing aerospace components, marine hardware, prosthetics, machined metals, or electronics, they need tools that deliver:

- Stable, repeatable measurements

- High-resolution probing

- CAD-integrated inspection routines

- Low maintenance and high durability

- Accuracy that holds up over years of operation

Helmel’s CMM lineup is uniquely suited to Maine’s diverse manufacturing climate, offering both laboratory-grade precision and rugged shop-floor stability.

As manufacturers across the state begin evaluating their options for dependable metrology equipment, many explore Helmel’s broad product selection through “Explore Our Full Line of Coordinate Measuring Machines”, a valuable resource for comparing manual, CNC, and custom CMM solutions.

Why Maine Companies Prefer Helmel Engineering CMMs

1. Built for Real-World Conditions

Helmel designs its CMMs to withstand the challenges of everyday production environments. Machines feature:

- Granite bases

- Precision-machined guideways

- Rigid frames

- Robust mechanical bearings

These components ensure accuracy is not compromised, even in facilities with temperature changes, moisture, vibration, or machining contaminants.

2. Made in the USA

All Helmel CMMs are manufactured in the United States, providing Maine companies with:

- Faster technical support

- Easy access to replacement parts

- Reliable customer service

- Better long-term machine stability

This American-made advantage helps reduce downtime and improves return on investment.

3. Intuitive, Powerful Software

Helmel’s GEOMET software supports both simple and advanced inspection tasks. It offers:

- Straightforward programming

- Clear reporting tools

- GD&T functionality

- Seamless CAD model integration

For Maine businesses training new employees or expanding quality control departments, GEOMET offers a manageable learning curve.

As Maine’s manufacturers grow and begin automating frequent inspection tasks, many look toward CNC CMM systems. “Learn More About Helmel’s CNC Coordinate Measuring Machines” an ideal reference point for exploring automation-ready solutions designed for efficiency and accuracy.

Industries Across Maine That Benefit from Helmel CMMs

Aerospace Manufacturing

Maine’s aerospace components require reliable precision. Helmel CMMs help ensure manufactured parts comply with strict aerospace standards.

Marine & Shipbuilding

For marine hardware, engine components, and custom metal fabrication, Helmel CMMs provide dependable inspection solutions suited for rugged working conditions.

Medical Device Manufacturing

Accuracy and traceability are essential in medical production. Helmel machines help ensure regulatory compliance and high-quality output.

Precision Machining & Metal Fabrication

Job shops across the state depend on CMMs to check prototypes, control production runs, and verify tight tolerances.

Electronics & Instrumentation

Small components require high-resolution measurements, and Helmel CMMs deliver the accuracy needed for micro-level inspections.

Research, Education & Training

Engineering programs, technical schools, and research labs value the durability and ease of use that Helmel CMMs provide.

Types of Helmel CMMs Popular in Maine

Manual CMMs

Perfect for entry-level inspection, prototype validation, and low-volume measurement tasks. These systems are known for reliability and simplicity.

CNC CMMs

Ideal for high-volume operations requiring automated routines, advanced measurement strategies, and efficiency improvements.

Shop-Floor CMMs

Engineered for durability, these systems operate reliably in active manufacturing environments without sacrificing accuracy.

Custom CMM Solutions

Helmel can tailor systems with special fixtures, probing accessories, and custom configurations to meet unique inspection needs.

What Makes Helmel Stand Out From Other CMM Manufacturers?

Superior Mechanical Engineering

Helmel CMMs are designed for long-term accuracy, not short-term compensation. Strong mechanics reduce wear, minimize drift, and ensure consistent results.

Lower Cost of Ownership

Without fragile air bearings and overly sensitive components, Helmel machines require less maintenance and offer a long lifespan.

Responsive U.S.-Based Support

Maine companies appreciate quick access to real engineers who understand the equipment and respond with practical, effective solutions.

When Maine manufacturers are ready to improve quality control, request a quote, or connect with a metrology expert “Contact Helmel Engineering for CMM Solutions in Maine” offers a direct pathway to expert guidance.

How to Choose the Right CMM for Your Maine Operation

Selecting the correct CMM depends on your facility’s:

- Measurement accuracy needs

- Part geometry and size

- Throughput requirements

- Operating environment

- Reporting and documentation processes

- Automation goals

Helmel’s team can help evaluate these factors to recommend the ideal system for your measurement demands whether your facility specializes in aerospace machining, medical manufacturing, or marine engineering.

Final Thoughts

As Maine’s manufacturing and technology sectors continue to grow, the demand for reliable, accurate, and durable metrology equipment becomes increasingly important. Helmel Engineering Products, Inc. stands out as a trusted American manufacturer that provides long-lasting CMM solutions designed for real-world shop-floor and laboratory environments.

For facilities aiming to enhance inspection accuracy, reduce scrap, and maintain consistent quality, Helmel’s CMMs offer unmatched value. With a focus on mechanical integrity, long-term precision, and user-friendly software, Helmel continues to be a leading CMM manufacturer serving Maine’s diverse industrial landscape.

Business name : Helmel Engineering Products, Inc.

phone number : 716-297-8644

website : https://helmel.com/

address : 6520 Lockport Road, Niagara Falls, NY 14305