Coordinate Measuring Machines (CMMs) in Indiana

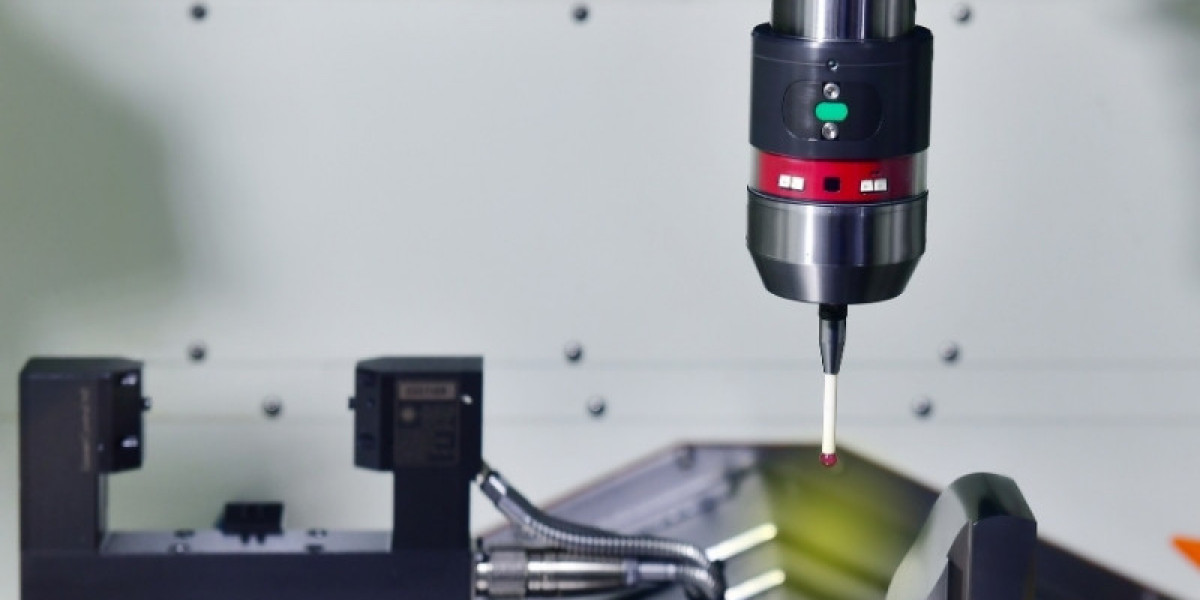

Indiana’s manufacturing economy is one of the strongest in the nation, driven by advanced machining, automotive production, aerospace, medical devices, industrial equipment, and precision metalworking. With such a heavy emphasis on engineering accuracy, the demand for dependable Coordinate Measuring Machines (CMMs) continues to grow. Manufacturers across the state rely on CMM systems to reduce scrap, maintain close tolerances, validate production quality, and streamline inspection workflows.

For companies searching for a trusted CMM manufacturer that provides durable, American-made precision equipment, Helmel Engineering Products, Inc. offers a proven solution. With more than 50 years of engineering excellence, Helmel delivers rugged, mechanically accurate CMMs that stand up to real-world manufacturing environments making them an ideal choice for Indiana’s high-precision industries.

Indiana’s Expanding Manufacturing Landscape

Indiana is recognized as one of the top manufacturing states in the country by percentage of workforce. Key sectors include:

- Automotive and transportation equipment

- Aerospace components and aviation machining

- Medical device production in the Warsaw orthopedic cluster

- Heavy machinery and industrial parts manufacturing

- Tool-and-die, prototyping, and advanced machining

- Electronics, sensors, and micro-precision parts

These industries depend on accurate, repeatable inspection. When dimensional tolerances tighten and product complexity increases, CMMs become essential tools for quality control.

Many manufacturers begin their research by reviewing regional resources such as Coordinate Measuring Machines (CMMs) in Indiana, which helps them understand the options available for their industry.

Why Indiana Manufacturers Trust Helmel CMMs

1. Mechanical Accuracy That Lasts

Unlike many machines that rely heavily on software compensation, Helmel builds accuracy into the structure of every CMM. Their design includes:

- Granite bases and precision ways

- Rigid frames engineered for long-term stability

- Durable mechanical bearings

- Meticulously machined components

This mechanical-first philosophy ensures consistent accuracy, minimal drift, and reduced maintenance an important advantage for Indiana’s high-volume production environments.

2. Made in the USA

Helmel Engineering designs and manufactures all CMMs in the United States. This results in:

- Reliable quality control

- Faster support and parts replacement

- Expert service from U.S.-based technicians

- Shorter lead times

Indiana companies appreciate the accessibility and long-term dependability that comes with American-made metrology equipment.

3. Powerful Yet Operator-Friendly Software

Helmel’s GEOMET software provides advanced inspection capability with a clean, intuitive interface. It offers:

- GD&T inspection

- CAD model integration

- Automated measurement sequences

- Real-time reporting

- Simplified program creation

This makes GEOMET suitable for both experienced metrology specialists and everyday operators.

As Indiana manufacturers adopt automation and expand production, many look to learn more about specialized measurement systems. Resources such as Explore Helmel CMM Solutions for Indiana Manufacturers are often used to compare manual vs. CNC CMM options and identify the ideal fit.

Key Indiana Industries that Benefit from CMM Technology

Automotive Manufacturing

Indiana is a leading automotive hub, producing engines, transmissions, and complex machined components. CMMs help ensure precision in every step of production.

Aerospace & Defense

Aerospace machining requires extremely tight tolerances. Helmel CMMs support inspection of turbine parts, housings, and structural components.

Medical Device Manufacturing

The Warsaw region is known as the “Orthopedic Capital of the World.” Manufacturers depend on CMM accuracy for implants, surgical instruments, and precision assemblies.

Tool & Die / Precision Machining

Machine shops across the state rely on Helmel CMMs for repeatable dimensional checks in prototyping and high-volume machining.

Industrial Equipment & Heavy Machinery

Large components require robust, reliable inspection tools an area where Helmel excels due to the mechanical strength of its systems.

Types of Helmel CMMs Ideal for Indiana Manufacturers

Manual CMMs

Great for low-volume inspection, prototype measurement, R&D labs, and hands-on quality control.

CNC Automated CMMs

Designed for larger production volumes, with consistent repeatability and fast inspection cycles.

Shop-Floor CMMs

Built to withstand active industrial environments, including vibration, temperature shifts, and machining contaminants.

Custom CMM Systems

Helmel provides custom configurations for unique measurement needs or complex part geometries.

Long-Term Advantages of Choosing Helmel

Exceptional Durability

Helmel CMMs often remain accurate for decades, far outlasting many modern alternatives.

Low Maintenance Requirements

Mechanical bearing systems and rugged design reduce ongoing calibration needs.

Dependable U.S. Support

Manufacturers in Indiana benefit from reliable access to experienced technicians.

Stable Accuracy in Real Manufacturing Conditions

Helmel systems perform consistently whether installed in a lab or on a busy production floor.

Selecting the Right CMM for Your Indiana Operation

Indiana companies should evaluate several factors when selecting a CMM, including:

- Part dimensions and geometry

- Inspection frequency

- Tolerance requirements

- Automation needs

- Shop-floor vs. controlled environment

- Reporting and documentation needs

- Software workflow

- Future scalability

Helmel Engineering works directly with Indiana manufacturers to identify the best CMM model based on their workflow and industry requirements.

Final Thoughts

Indiana’s manufacturing sector continues to grow, and with it comes the need for reliable, accurate, and long-lasting dimensional inspection equipment. Helmel Engineering Products, Inc. provides American-made CMMs designed for performance, durability, and true mechanical accuracy.

For companies seeking more details or comparing available models, resources such as Helmel CMM Options for Indiana offer valuable insight into the right solution for any production environment.

Business name : Helmel Engineering Products, Inc.

Phone number : 716-297-8644

Website : https://helmel.com/

Address : 6520 Lockport Road, Niagara Falls, NY 14305