In the rice milling industry, achieving superior rice quality depends not only on advanced machinery but also on the reliability of critical components. One such essential component is the rice rubber polisher, widely used to enhance rice appearance and finish. A trusted rice rubber polisher supplier plays a crucial role in ensuring consistent performance, durability, and efficiency in rice polishing operations.

As rice millers increasingly focus on quality, yield, and cost control, choosing the right supplier for rice rubber polishers has become a strategic business decision.

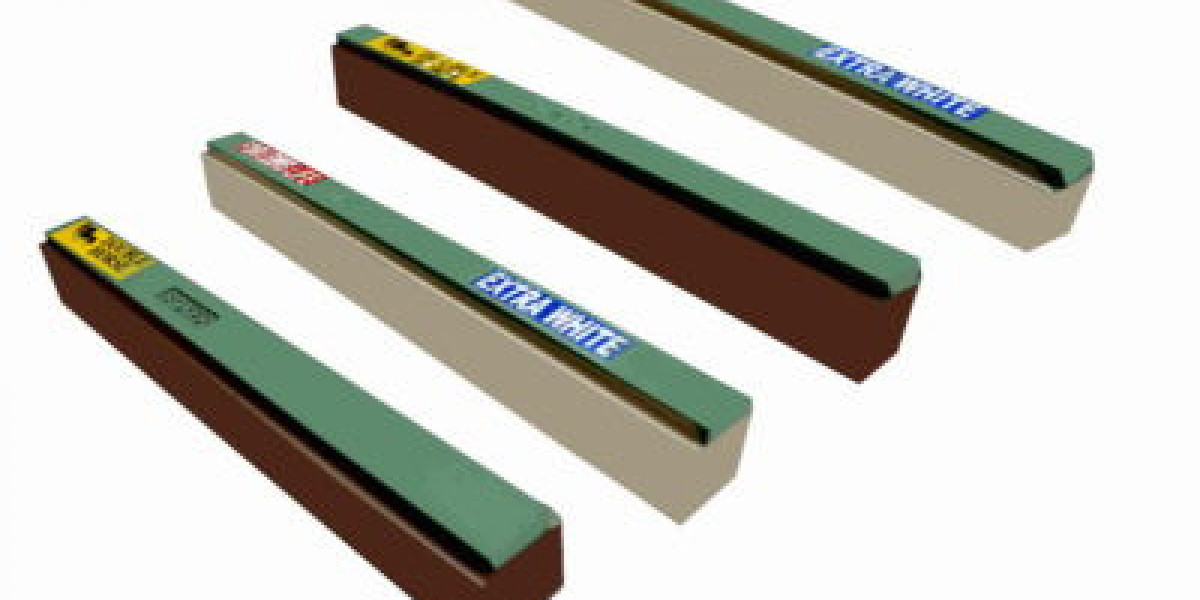

What Is a Rice Rubber Polisher?

A rice rubber polisher is a polishing component or system that uses rubber-based friction to remove remaining bran layers from rice kernels after whitening. Unlike harsh abrasive systems, rubber polishers offer controlled and gentle polishing, helping maintain the grain’s natural structure while delivering a smooth and glossy surface.

Rice rubber polishers are commonly used in modern rice mills to improve rice quality, reduce breakage, and enhance overall market value.

Importance of a Reliable Rice Rubber Polisher Supplier

Not all rice rubber polishers perform the same way. The difference lies in the quality of rubber material, manufacturing precision, and supplier expertise. A professional rice rubber polisher supplier ensures that the products supplied meet industry standards and perform consistently under continuous milling conditions.

Working with a reliable supplier helps rice mill owners:

Achieve uniform polishing results

Reduce broken rice percentage

Improve operational efficiency

Minimize machine downtime

Lower maintenance and replacement costs

A dependable supplier becomes a long-term partner rather than just a product provider.

Key Qualities of a Trusted Rice Rubber Polisher Supplier

Top rice rubber polisher suppliers share certain characteristics that set them apart in the competitive rice milling industry.

High-Quality Rubber Materials

A professional supplier sources or manufactures rice rubber polishers using premium natural and synthetic rubber compounds. These materials provide the right balance of friction, elasticity, and wear resistance for effective polishing.

Consistent Product Quality

Consistency is critical in rice milling. A reliable rice rubber polisher supplier ensures uniform hardness, density, and dimensions across all products, delivering predictable and stable performance.

Wide Product Range

Leading suppliers offer a variety of rice rubber polishers in different sizes, hardness levels, and designs to suit different rice varieties and polishing machines.

Customization Options

Every rice mill has unique requirements. A good supplier provides customized solutions based on machine type, rice variety, production capacity, and desired polishing finish.

Timely Supply and Support

On-time delivery and dependable after-sales support are essential. A professional rice rubber polisher supplier ensures uninterrupted supply and technical guidance when needed.

Role of Rice Rubber Polisher Supplier in Rice Quality Enhancement

The final appearance of rice significantly impacts its market value. A high-quality rice rubber polisher supplied by a trusted vendor helps achieve:

Smooth and glossy rice surface

Uniform polishing across grains

Reduced heat generation during polishing

Lower grain damage and breakage

These factors directly contribute to premium rice quality that meets both domestic and export market standards.

Applications of Rice Rubber Polishers Supplied by Industry Experts

Rice rubber polishers supplied by reliable suppliers are widely used in:

Commercial rice mills

Export-oriented rice processing units

Small and medium-scale milling plants

Integrated grain processing facilities

They are suitable for polishing various rice types, including raw rice, parboiled rice, long-grain rice, and short-grain rice.

Benefits of Partnering with the Right Rice Rubber Polisher Supplier

Choosing the right rice rubber polisher supplier offers long-term operational and financial benefits.

Improved Milling Efficiency

High-quality polishers ensure smooth polishing operations with minimal disruptions.

Cost Savings

Durable rubber polishers reduce frequent replacements, lowering maintenance and operational costs.

Better Yield

Gentle polishing action results in fewer broken grains and higher whole rice output.

Consistent Product Quality

Uniform polishing improves rice appearance, helping mills build trust and reputation in the market.

Business Growth Support

Reliable suppliers understand industry needs and support mills in scaling production efficiently.

Manufacturing and Quality Control Standards

A professional rice rubber polisher supplier follows strict quality control measures to ensure product reliability. This includes:

Careful selection of raw rubber materials

Precision molding and curing processes

Dimensional accuracy checks

Performance and durability testing

Such quality-focused practices ensure that each rice rubber polisher delivers consistent performance throughout its service life.

Innovation and Industry Experience

Experienced rice rubber polisher suppliers continuously upgrade their product designs based on market feedback and technological advancements. By understanding evolving rice milling practices, they offer solutions that improve productivity, reduce losses, and enhance rice quality.

Industry expertise allows suppliers to recommend the right polisher specifications for different milling conditions, helping customers achieve optimal results.

How to Choose the Right Rice Rubber Polisher Supplier

When selecting a rice rubber polisher supplier, rice mill owners should consider:

Supplier’s industry experience

Quality of rubber materials used

Range and customization capabilities

Reliability of supply and delivery timelines

Technical support and customer service

Choosing a supplier that excels in these areas ensures long-term value and dependable milling performance.

Conclusion

A trusted rice rubber polisher supplier is a vital partner in the success of modern rice milling operations. By supplying high-quality, durable, and efficient rubber polishers, the right supplier helps rice mills improve rice appearance, reduce breakage, and enhance overall productivity.

Investing in a reliable rice rubber polisher supplier is not just about sourcing a component—it is about ensuring consistent quality, operational efficiency, and sustainable growth in a competitive rice milling market.