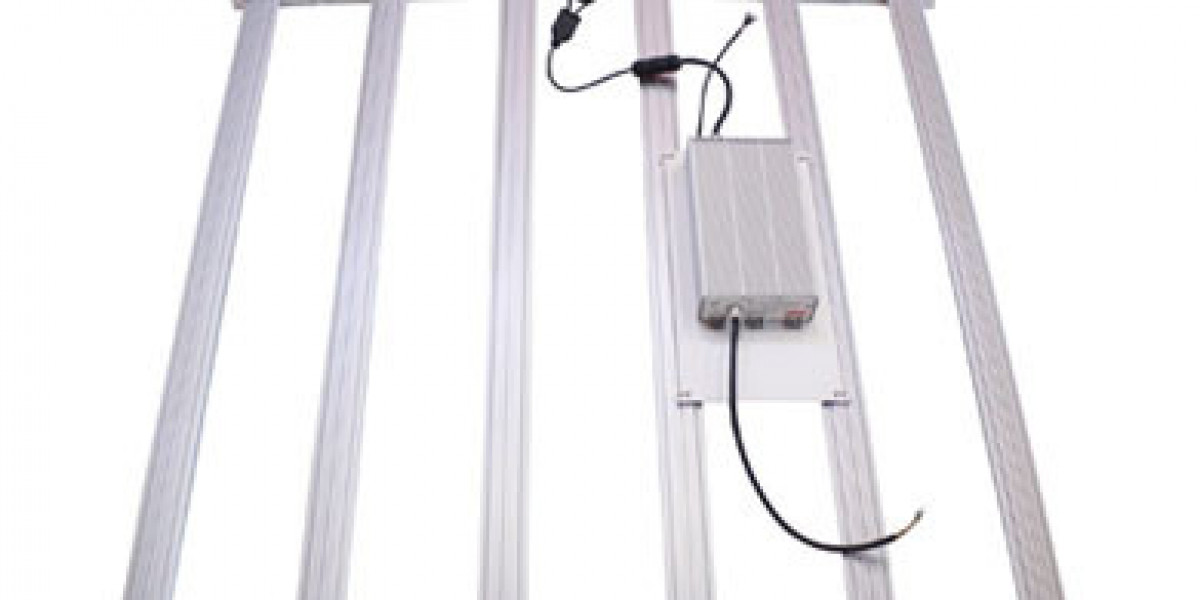

In today’s fast-moving industrial landscape, speed, accuracy, and consistency are essential for business success. A packaging machine plays a crucial role in helping manufacturers meet these demands. From food and beverages to pharmaceuticals, cosmetics, and consumer goods, packaging machines streamline operations while ensuring product safety and quality. As businesses scale and competition increases, automated packaging solutions have become a necessity rather than a luxury.

What Is a Packaging Machine?

A packaging machine is an automated or semi-automated system designed to pack products efficiently and consistently. These machines perform tasks such as filling, sealing, wrapping, labeling, coding, and palletizing. By reducing manual involvement, packaging machines minimize errors, improve hygiene, and increase production output. They are available in various configurations to handle solids, liquids, powders, and fragile items.

Types of Packaging Machines

There are several types of packaging machines, each designed for specific applications:

Form-Fill-Seal Machines: Create packages, fill them with products, and seal them in a single process

Bottle Filling Machines: Commonly used in beverage, cosmetic, and chemical industries

Vacuum Packaging Machines: Remove air to extend shelf life, especially in food packaging

Shrink Wrapping Machines: Wrap products tightly for protection and visual appeal

Labeling and Coding Machines: Apply labels, barcodes, and batch information accurately

Choosing the right machine depends on product type, production volume, and packaging requirements.

Benefits of Using Packaging Machines

Investing in a packaging machine offers multiple advantages:

Increased Efficiency: High-speed operations significantly improve production capacity

Cost Savings: Reduced labor costs and lower material waste

Consistent Quality: Uniform packaging improves brand image and customer trust

Improved Hygiene: Essential for food and pharmaceutical industries

Scalability: Easy to upgrade as production demands grow

These benefits make packaging machines a long-term asset for businesses aiming to improve operational performance.

Applications Across Industries

Packaging machines are widely used across various sectors, including:

Food and beverage manufacturing

Pharmaceutical and healthcare products

Cosmetics and personal care

Chemical and industrial goods

E-commerce and logistics

Their flexibility allows businesses to customize packaging formats while maintaining efficiency.

Future Trends in Packaging Machines

Modern packaging machines are evolving with smart technology. Features such as IoT monitoring, touch-screen controls, predictive maintenance, and energy-efficient systems are becoming standard. These advancements help businesses track performance, reduce downtime, and improve sustainability. Automation and AI-driven packaging solutions are shaping the future of manufacturing worldwide.

Conclusion

A packaging machine is an essential tool for any business focused on productivity, quality, and growth. By automating repetitive tasks and ensuring consistent packaging, these machines help companies stay competitive in demanding markets. Whether for small-scale operations or large manufacturing plants, investing in the right packaging machine leads to improved efficiency, reduced costs, and long-term success.