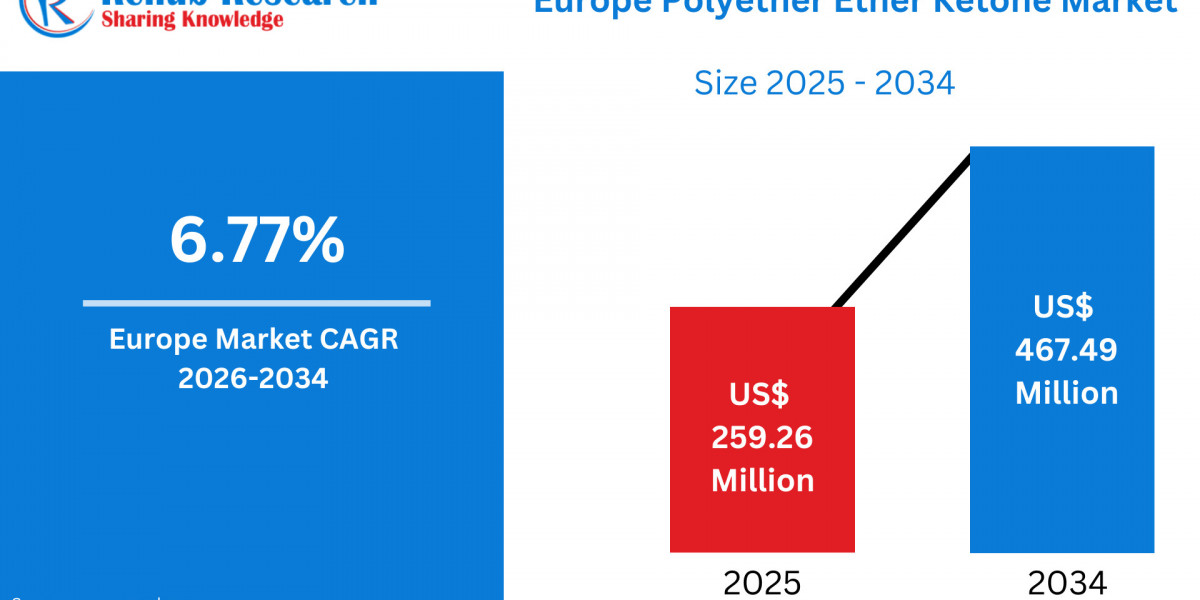

Europe Polyether Ether Ketone Market Size & Forecast 2026–2034

According to Renub Research Europe Polyether Ether Ketone (PEEK) market is poised for strong and sustained growth during the forecast period 2026–2034. Valued at US$ 259.26 million in 2025, the market is projected to reach US$ 467.49 million by 2034, expanding at a compound annual growth rate (CAGR) of 6.77%. This upward trajectory is driven by the increasing penetration of high-performance polymers across critical industries such as aerospace, automotive, medical, electronics, and industrial machinery.

PEEK’s exceptional mechanical strength, thermal resistance, and chemical stability position it as a premium alternative to metals and conventional engineering plastics. As European industries intensify their focus on lightweighting, sustainability, and long-term performance, PEEK continues to gain strategic importance across both legacy and emerging applications.

Download Free Sample Report:https://www.renub.com/request-sample-page.php?gturl=europe-polyether-ether-ketone-market-p.php

Overview of the Europe Polyether Ether Ketone Market

Polyether Ether Ketone is a semi-crystalline, high-performance thermoplastic recognized for its ability to maintain structural integrity at temperatures exceeding 250°C, while offering outstanding resistance to chemicals, wear, and fatigue. These characteristics make PEEK highly suitable for applications operating in extreme environments where conventional polymers fail.

Across Europe, PEEK adoption is reinforced by the region’s strong emphasis on precision engineering, regulatory compliance, and material innovation. Aerospace manufacturers rely on PEEK to replace metal components, reducing aircraft weight while maintaining safety and durability. In automotive manufacturing, particularly for electric vehicles, PEEK is used in high-temperature connectors, battery components, and drivetrain parts.

The medical sector represents one of the fastest-growing application areas for PEEK in Europe. Its biocompatibility, radiolucency, and bone-like mechanical properties make it ideal for spinal implants, dental restorations, and trauma devices. Furthermore, compatibility with advanced manufacturing techniques such as CNC machining and high-temperature additive manufacturing further expands PEEK’s relevance in modern European production ecosystems.

Growth Drivers in the Europe Polyether Ether Ketone Market

Increasing Demand for High-Performance Engineering Plastics

Europe’s transition toward advanced manufacturing and sustainable industrial systems is significantly boosting demand for high-performance engineering plastics. Industries are actively replacing metal components with lightweight polymers to improve energy efficiency, reduce emissions, and extend component lifespan.

PEEK offers an optimal balance of strength, thermal stability, and chemical resistance, making it a preferred choice for demanding environments. In aerospace and automotive sectors, carbon-reduction mandates encourage weight savings that PEEK effectively delivers. Electronics manufacturers benefit from its excellent dielectric properties, enabling reliable performance in compact and high-voltage components.

In September 2025, Essentra Components launched a new range of PEEK fasteners designed for extreme operating conditions, reflecting growing industrial confidence in PEEK-based solutions.

Expansion of Medical Applications and Biocompatibility Advantages

The European medical device industry is increasingly adopting PEEK due to its proven biocompatibility and mechanical similarity to human bone. Compared to metallic implants, PEEK allows clearer MRI and X-ray imaging, improving post-operative diagnostics and long-term patient outcomes.

Applications include spinal cages, cranial implants, dental frameworks, and trauma fixation systems. Aging demographics across Europe and rising incidences of degenerative orthopedic conditions are further accelerating demand. Regulatory frameworks in countries such as Germany, France, and the UK encourage innovation in implant materials, supporting market expansion.

In October 2023, Victrex plc introduced Victrex Pharmaceutical Contact 101, a new PEEK grade designed for pharmaceutical contact and drug-delivery applications, reinforcing the material’s versatility in healthcare.

Growth of Additive Manufacturing and Precision Engineering

Europe’s leadership in additive manufacturing and Industry 4.0 adoption is creating new growth avenues for PEEK. High-temperature 3D printing enables the production of complex, lightweight, and customized components with minimal material waste.

PEEK filaments and powders are increasingly used in aerospace, medical, and automotive prototyping, as well as in low-volume production of high-value parts. The material’s dimensional stability and mechanical strength make it ideal for functional printed components that must endure harsh operational conditions.

In May 2023, Evonik Industries AG partnered with ProductionToGo to distribute INFINAM PEEK filaments across the EU, UK, and Switzerland, highlighting growing commercial momentum in additive manufacturing applications.

Challenges in the Europe Polyether Ether Ketone Market

High Production Costs and Processing Complexity

Despite its performance advantages, PEEK faces adoption barriers due to its high production and processing costs. Manufacturing requires high-purity raw materials and tightly controlled conditions, resulting in significantly higher prices compared to standard engineering plastics.

Processing PEEK also demands specialized equipment capable of handling extreme temperatures, limiting accessibility for small- and medium-scale manufacturers. As a result, cost-sensitive industries may opt for alternative materials unless performance requirements justify the investment.

Competition from Substitute Materials

PEEK competes with other high-performance polymers such as polyetherimide (PEI), polysulfone (PSU), and polyphenylene sulfide (PPS), which often provide adequate performance at lower costs. In certain applications, advanced composites and aluminum alloys offer competitive strength-to-weight ratios.

In the medical sector, titanium remains a well-established implant material with long clinical acceptance. Continuous innovation in polymer blends and composites further intensifies competition, challenging PEEK manufacturers to expand adoption beyond premium applications.

Europe Glass-Filled Polyether Ether Ketone Market

Glass-filled PEEK is gaining traction across Europe due to enhanced stiffness, creep resistance, and dimensional stability. The reinforcement improves performance in load-bearing and high-temperature environments, making it suitable for aerospace, automotive, and industrial machinery components.

Applications include gears, bearings, pump parts, electrical connectors, and compressor components. In automotive manufacturing, glass-filled PEEK supports metal replacement initiatives for under-the-hood applications. Sustainability regulations favor materials with long service life, positioning glass-filled PEEK as a durable and efficient engineering solution.

Europe Aerospace Polyether Ether Ketone Market

The European aerospace industry represents one of the most significant growth drivers for PEEK. Aircraft manufacturers increasingly specify PEEK for brackets, seals, bearings, wire insulation, and cabin components due to its excellent flame-smoke-toxicity compliance and resistance to jet fuel and lubricants.

As the industry advances toward electric aircraft, hybrid propulsion, and lightweight structural designs, PEEK’s role continues to expand. Additive manufacturing further enhances its appeal by enabling complex geometries, reduced lead times, and cost-efficient production of specialized aerospace components.

Europe Automotive Polyether Ether Ketone Market

Strict emission regulations and rapid electrification are reshaping Europe’s automotive industry, driving demand for lightweight, high-temperature-resistant materials. PEEK is increasingly used in connectors, fuel systems, braking components, transmission parts, and EV battery systems.

Its excellent dielectric strength and thermal stability make it especially valuable in electric and hybrid vehicles. By replacing metal components, PEEK contributes to improved vehicle efficiency, reduced maintenance, and extended service life, aligning with Europe’s sustainability goals.

Europe Medical Polyether Ether Ketone Market

The medical sector is among the fastest-growing consumers of PEEK in Europe. Applications span spinal implants, dental restorations, trauma fixation, and cranial reconstruction. PEEK’s radiolucency allows accurate imaging, while its lightweight nature improves patient comfort.

The rise of patient-specific implants through medical 3D printing further strengthens PEEK demand. Advanced healthcare infrastructure, high R&D investment, and favorable regulatory pathways support continuous innovation in PEEK-based medical solutions.

Country-Wise Market Analysis

France Polyether Ether Ketone Market

France’s strong aerospace and medical device industries make it a major contributor to European PEEK demand. Aerospace applications dominate, supported by sustainability-driven lightweighting initiatives. In March 2024, DEMGY Group partnered with Drake Plastics to distribute machinable PEEK shapes across France.

Germany Polyether Ether Ketone Market

Germany stands as one of Europe’s most important PEEK markets due to its automotive, industrial machinery, and medical technology leadership. In October 2023, Evonik launched VESTAKEEP® carbon-fiber-reinforced PEEK filaments for long-term 3D-printed medical implants, reinforcing Germany’s innovation leadership.

United Kingdom Polyether Ether Ketone Market

The UK market is driven by strong adoption in medical devices, aerospace, and electronics. In 2023, Victrex introduced an implantable PEEK-OPTIMA polymer optimized for medical additive manufacturing, strengthening the UK’s leadership in medical PEEK applications.

Netherlands Polyether Ether Ketone Market

The Netherlands benefits from advanced electronics manufacturing, medical technology innovation, and a strong focus on sustainable production. PEEK is increasingly used in semiconductor equipment, medical implants, and chemical processing applications due to its durability and dielectric performance.

Market Segmentations

By Type

- Unfilled

- Carbon-filled

- Glass-filled

By End Use

- Aerospace

- Automotive

- Electrical & Electronics

- Industrial & Machinery

- Medical

- Others

By Country

France, Germany, Italy, Spain, United Kingdom, Belgium, Netherlands, Russia, Poland, Greece, Norway, Romania, Portugal, Rest of Europe

Competitive Landscape and Company Analysis

The Europe PEEK market is characterized by innovation, strategic partnerships, and continuous material development. Key players include:

- BARLOG plastics GmbH

- Caledonian Industries Ltd.

- Ensinger GmbH

- Evonik Industries AG

- J.K. Overseas

- Pan Jin Zhongrun High Performance Polymer Co. Ltd.

- Saudi Basic Industries Corporation

- Solvay SA

- Victrex plc

Each company is evaluated across five viewpoints: overview, key personnel, recent developments, SWOT analysis, and revenue performance.