In industrial environments, cooling systems face constant stress due to high temperatures, pressure, and continuous operation. These conditions can lead to leaks and inefficiencies that threaten productivity and system integrity. Maintaining peak performance and minimising downtime is essential to keeping operations smooth and cost-effective. This is where the coolant system stop leak solutions come in. These specialised products provide a quick, reliable fix to small leaks without requiring time-consuming disassembly. By effectively sealing cracks and pinholes, stop leak products offer a preventive and corrective measure that boosts system uptime and efficiency across various industrial applications.

What Is a Coolant System Stop Leak?

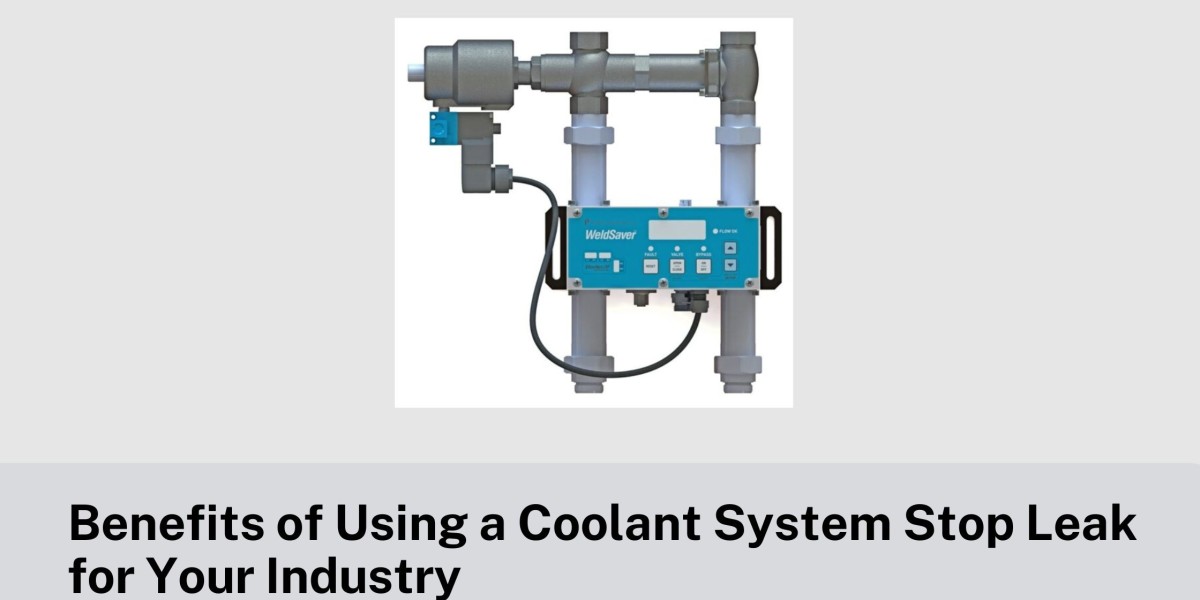

A coolant system stop leak is a chemical product designed to seal small leaks in cooling systems. It circulates through the system and forms a durable seal over cracks or holes when exposed to air or pressure changes. Available in various forms, such as liquids, powders, and tablets, stop leak products are compatible with most industrial systems, including machines, HVAC units, and generators.

Common Industrial Applications

Coolant stop leak solutions are used across many industrial sectors. In manufacturing plants, they help maintain optimal cooling in heavy equipment and assembly lines. Construction and mining machinery benefit from quick leak-sealing properties, reducing on-site repair needs. Maintaining cooling efficiency is critical for uptime in power generation, especially in turbines and backup generators.

Key Benefits of Using a Coolant System Stop Leak

Minimises Downtime

Coolant stop leak products offer a fast, on-the-spot solution for minor leaks without requiring complete disassembly. When equipment breaks down, time is money—especially in continuous operations. A stop leak product can be added directly to the cooling system, allowing it to continue running while the leak is sealed. This significantly reduces the need for unplanned shutdowns or extended repair times.

Cost-Effective Maintenance

One of the most compelling reasons to use a coolant to stop leaks is its cost-efficiency. Replacing damaged parts in an industrial cooling system can be expensive and time-consuming. Stop leak products help avoid those costs by providing a temporary yet effective repair for small leaks. They also reduce labour expenses associated with part replacements or system overhauls.

Extends Equipment Life

If left untreated, coolant leaks can show to overheating, corrosion, and long-term damage. To help prevent future leaks, stop leak products, seal small breaches, and create protective barriers inside the cooling system. These solutions protect internal components from rust and scale buildup by maintaining proper coolant levels and reducing exposure to air and contaminants.

Improves Operational Efficiency

Proper pressure and temperature regulation are essential for cooling systems to function effectively. Even small leaks can disrupt this balance, leading to inefficient cooling and increased energy use. Coolant system stop leak products restore system integrity, enabling it to operate at optimal undertaking levels. This helps achieve consistent production outputs and reduces strain on associated systems like machines and compressors.

Environmentally Friendly

Uncontrolled coolant leaks can release harmful chemicals into the environment, contaminating soil and water sources. By sealing leaks quickly, coolant stop leak products help prevent such incidents. Many modern formulations are designed with eco-friendly elements that are non-toxic and biodegradable, making them safer for both users and the environment. In industries aiming to meet environmental regulations and sustainability goals, using stop leak solutions is a practical step toward reducing their ecological footprint while maintaining operational performance.

Quick and Easy Application

Coolant stop leak products are user-friendly and require minimal technical expertise to apply. They can be poured directly into the radiator or reservoir, making them ideal for maintenance teams that need to act swiftly without specialized tools. This ease of use reduces time spent troubleshooting and reduces human error risk during urgent repair situations.

Versatile Compatibility

Modern stop leak solutions are compatible with various coolant types and system materials, including aluminium, plastic, and steel components. This flexibility allows them to be used across multiple industries and equipment types—whether automotive, heavy machinery, agricultural equipment, or industrial cooling systems—without risk of damaging internal components.

When and How to Use Coolant Stop Leak?

If your system shows signs like a gradual loss of coolant, overheating, or visible drips, a stop leak product may be the right solution. Start by ensuring the system is cool and clean, then follow product instructions for proper dosage and application. Typically, you add the product directly to the radiator or coolant reservoir. Allow the machine or system to run so the product can circulate and seal the leak. While effective for minor leaks, stop leak should not be used for large cracks or damaged components.

Conclusion

Coolant system stop leak products offer a practical solution for maintaining industrial system uptime and efficiency. Providing quick, cost-effective fixes for small leaks, they help reduce maintenance costs, extend equipment lifespan, and support environmental safety. However, it’s crucial to use these products properly and choose high-quality formulations suited to your specific application. Consider working with trusted suppliers like Proteus Industries Inc., a leader in fluid flow monitoring and temperature control solutions for reliable cooling system management. Their expertise ensures your industrial systems operate safely and efficiently, minimising the risk of unexpected downtime.

FAQS

Is stopping the leak a permanent solution?

No, it's typically a temporary fix.

Can it damage the cooling system?

Quality products generally won’t, but overuse or low-grade formulas can cause blockages.

How often can it be used?

Only as needed—frequent use indicates a larger issue that a professional should address.

Does it work on all materials?

Most products are compatible with metal and rubber, but always check the label.

Can it be used in diesel and gas machines?

Yes, but choose the correct type for your specific machine and application.