Vacuum technology keeps to evolve unexpectedly, introducing revolutionary methods that enhance precision, performance, and reliability in business techniques. Yet, amidst this advancement, rotary vane vacuum pumps have maintained a robust presence in many sectors. Known for his or her sturdiness, cost-effectiveness, and reliable performance, these pumps have long been a staple in applications ranging from production and pharmaceuticals to food processing and laboratory operations. Despite the upward thrust of more recent technology, many an commercial products manufacturer still integrates rotary vane pumps into crucial structures, elevating a key question: will those conventional pumps retain to maintain their ground within the future?

o

The Fundamentals of Rotary Vane Vacuum Pumps

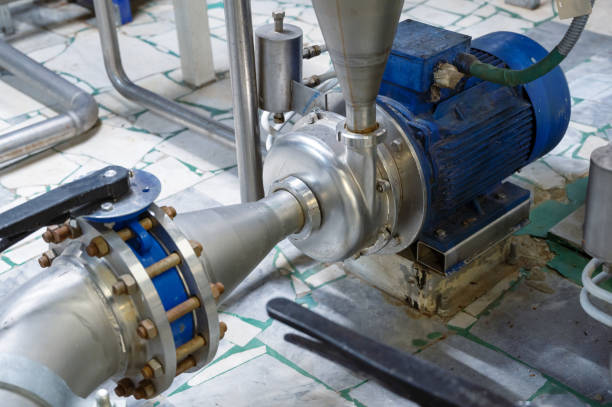

Rotary vane vacuum pumps perform using a simple but effective mechanism. At their center, those pumps use a rotor positioned inner a cylindrical housing. The rotor is offset and equipped with sliding vanes, which create chambers of varying sizes as the rotor turns. This technique generates a vacuum by trapping fuel and decreasing its volume because it moves thru the pump.

This technology has been subtle over decades and is especially noted for its clean operation, low upkeep desires, and steady vacuum generation. The pumps can be both oil-sealed or dry-jogging, with each type having wonderful advantages relying on the utility. These core functions have made them exceedingly valued in industrial operations where reliability and fee-efficiency are paramount.

Historical Relevance and Longstanding Use

The rotary vane design dates returned to the early 20th century and has due to the fact established itself in limitless settings. It has been extensively adopted to be used in air conditioning systems, medical vacuum gadgets, packaging machinery, and laboratory system. This lengthy history of success is not simply because of inertia or loss of options; alternatively, it reflects the pump's capacity to satisfy essential operational necessities with minimum problem.

Over the years, many inventions have emerged in vacuum generation, consisting of dry screw, scroll, and turbomolecular pumps. However, rotary vane pumps maintain to keep their own in packages that require moderate vacuum levels and non-stop operation underneath various situations.

The Rise of Competing Technologies

While rotary vane pumps remain extensively used, the past two decades have witnessed the emergence of advanced vacuum answers that cater to extra specialized or excessive requirements. Technologies which includes dry screw pumps and turbomolecular systems provide oil-free operation, deeper vacuum levels, or faster pumping speeds. These innovations are particularly crucial in high-tech fields like semiconductor production, biotechnology, and area research.

These more moderen technology are frequently lauded for their capacity to maintain purifier environments and reduce infection dangers—critical in sectors where purity is non-negotiable. Their virtual integration, unique control systems, and power-saving designs are also fantastically appealing in industries that prioritize automation and environmental sustainability.

Efficiency Comparisons in Operational Contexts

When comparing efficiency, rotary vane vacuum pumps won't continually match the high-overall performance metrics of modern-day alternatives. However, their performance should no longer be brushed off outright. In many low- to mid-vacuum programs, they provide extra than enough performance with lower initial funding and renovation costs.

Additionally, more moderen vacuum systems frequently require greater sophisticated infrastructure and training, making them much less handy for smaller or price range-aware operations. Rotary vane pumps, via contrast, can be applied with minimal support structures, making them perfect for ordinary and decentralized applications.

Cost Considerations and Return on Investment

One of the important thing reasons rotary vane pumps continue to be relevant is their value-effectiveness. The initial purchase charge is normally lower than that of more moderen vacuum structures. Furthermore, their operational simplicity interprets to fewer upkeep, longer provider intervals, and decreased training necessities.

In applications in which ultra-excessive vacuum stages are pointless, investing in high-stop structures might not provide a tangible return. Rotary vane pumps, in those cases, offer the necessary overall performance without inflating capital or operational budgets. For many industries, especially the ones in transitional economies or rising markets, this stability of cost and capability is distinctly appealing.

Maintenance and System Longevity

Maintenance is any other vital aspect in pump choice. Rotary vane vacuum pumps are acknowledged for his or her straightforward upkeep routines. Oil adjustments, vane replacements, and seal inspections can be carried out with out complicated disassembly or specialized knowledge.

Modern alternatives, even as advanced, regularly involve higher complexity in terms of provider. Maintenance can require exceptionally skilled technicians and downtime that isn't always feasible for all operations. The ease with which rotary vane pumps may be serviced regularly translates into better uptime and prolonged lifecycle, contributing further to their monetary viability.

Industrial Versatility and Adaptation

Rotary vane pumps exhibit first-rate versatility, able to coping with a wide range of gases and accommodating one of a kind working environments. They carry out reliably in industries as diverse as food processing, environmental tracking, metallurgy, and car manufacturing.

Their compact footprint and modular construction additionally lead them to appropriate for integration into mobile or space-restricted structures. Additionally, many manufacturers have developed superior fashions with advanced sealing, corrosion resistance, and noise discount, thereby extending the variety of appropriate programs.

Evolving the Traditional: Technological Enhancements

Rather than becoming out of date, rotary vane vacuum pumps have themselves evolved. Advances in materials technological know-how and engineering have allowed for the improvement of pumps with higher vane existence, reduced oil consumption, and better tolerance to technique contaminants.

Control systems have also been included into current fashions, offering users higher actual-time facts and system control. These improvements help near the performance hole between rotary vane pumps and more recent vacuum technology, ensuring they stay a possible alternative in each legacy and destiny-ready structures.

Environmental and Regulatory Factors

Modern industrial environments must adhere to increasingly more stringent environmental standards. While rotary vane pumps have historically been visible as less eco-friendly due to oil usage, latest models have progressed in this regard. Oil mist filters, strength-efficient vehicles, and better oil containment structures have made those pumps purifier and greater compliant with present day rules.

For programs where oil contamination is a challenge, dry-running rotary vane fashions provide a feasible alternative. These variations exhibit that the technology may be delicate to satisfy each operational and environmental expectations.

Future Industrial Trends and Market Demand

As international enterprise maintains to prioritize sustainability, automation, and digitalization, the destiny of vacuum technology will in all likelihood focus on structures that provide smart integration and extremely-easy operation. That stated, now not all industries require or can justify the prices related to these features.

Rotary vane pumps will likely continue to serve a foundational role in sectors wherein slight vacuum ranges and simple operation are enough. Their presence in developing areas is anticipated to stay strong, specially wherein infrastructure does no longer assist high-maintenance or rather specialised structures.

Coexistence with Emerging Technologies

Rather than being changed, rotary vane pumps are increasingly visible as complementary to more recent technologies. Many centers now operate hybrid vacuum systems, in which a couple of pump types are used in tandem to deal with unique procedure levels. For example, a rotary vane pump might handle hard vacuum responsibilities while a turbomolecular pump manages high-vacuum obligations.

This layered technique lets in facilities to optimize performance with out overcommitting sources to a unmarried pump type. Rotary vane pumps in such configurations continue to offer large price, mainly in the course of startup levels or in help roles.

Training, Familiarity, and Workforce Readiness

Another not noted gain of rotary vane vacuum pumps is their familiarity among industrial technicians. The knowledge and ability required to function and maintain these systems are tremendous and well-documented.

Introducing a brand new vacuum era often involves huge training and adjustment time. In contrast, rotary vane pumps can be quickly integrated and maintained by existing workforce, which makes them an appealing desire for corporations looking to avoid transitional challenges.

Final Thoughts: Enduring Utility in a Changing Landscape

The technological panorama of vacuum systems is definitely converting, and the future will keep to introduce advanced options that address niche or surprisingly stressful programs. However, this does not sign the stop for rotary vane vacuum pumps. Their reliability, affordability, and flexibility make certain they remain relevant, specifically in contexts wherein their overall performance parameters align with operational desires.

As the economic area maintains to evolve, the rotary vane design is probably to evolve along with it. Through incremental innovation and strategic integration, these pumps will continue to serve both installed industries and rising markets. For any industrial products manufacturer, knowing the strengths and limitations of every vacuum technology is important in crafting structures that are not most effective green but also sustainable and economically sound.