Have you ever wondered how those sleek, shiny displays in Dubai's malls come to life? It's all thanks to the magic of acrylic fabrication.

In a city known for its cutting-edge design and luxury, acrylic plays a vital role in shaping everything from eye-catching store displays to innovative architectural features. If you're curious about how acrylic is transforming spaces in Dubai, you're in the right place.

We're here to explore why acrylic is such a popular material and how it can meet your design needs. Whether you're an interior designer, a business owner, or just someone with a love for modern design, this guide will give you the insights you need to understand acrylic's many benefits. Plus, you'll learn practical tips on how to choose the right fabricator for your projects in Dubai.

Understanding Acrylic Materials

Let's dive into acrylic materials. They're super popular for many reasons. You might wonder, what makes acrylic so special? It boils down to the different types, unique properties, and handy features. Let's look at these in detail.

Types of Acrylic: Cast vs. Extruded

Acrylic comes in two main types: cast and extruded. Cast acrylic is known for its durability and smooth finish. It's great for polished displays and high-quality signage. Need precision? Cast's the one you want. On the other hand, extruded acrylic is more budget-friendly. It's perfect for projects needing lots of material, like large sheets for windows or partitions.

Key Properties and Characteristics

Acrylic is lightweight but strong. It's resistant to scratches and shattering, unlike regular glass. This makes it ideal for hectic places like malls or public spaces. Plus, it's crystal clear and can be tinted or frosted, depending on your need. Imagine sleek, transparent surfaces that don’t break easily. That's acrylic for you.

Advantages of Acrylic Materials

You get plenty of benefits with acrylic. First off, it's versatile. You can cut, mold, and bend it into practically any shape. Acrylic works indoors and outdoors because it resists UV light. Plus, it's lightweight, so handling, installing, and transporting are easier. Whether for an art installation or retail display, acrylic’s flexibility is unbeatable.

Common Myths About Acrylic

Some folks think acrylic is fragile or hard to maintain. Not true. Acrylic is tough and easy to clean with the right products. You might also hear acrylic scratches easily. While it can scratch, using proper care methods can keep it looking new. Regular cleaning and avoiding harsh chemicals do the trick.

Environmental Considerations

You might wonder about acrylic's eco-friendliness. Some acrylics are made from recycled materials. This choice helps reduce environmental impact. Plus, acrylic lasts a long time, reducing the need for frequent replacements. This durability means less waste. When considering materials for your Dubai project, choose eco-friendly acrylic options for a greener solution.

Understanding these basics helps you see why acrylic is a top choice in Dubai fabrication. Whether for sturdy signage or creative displays, acrylic offers durability, flexibility, and style.

Acrylic Fabrication Techniques

Let's talk about acrylic fabrication techniques. This section covers cutting, shaping, and joining acrylic. Understanding these methods can help you choose the right approach for your project.

Cutting Techniques: Laser Cutting, CNC, and More

You have several ways to cut acrylic. Laser cutting and CNC are top choices. Laser cutting uses a focused beam to make clean, precise cuts. It's great for intricate designs or small details. CNC machines, on the other hand, use computer-controlled routers. They are perfect for larger cuts or thicker materials. Both methods ensure smooth edges and help reduce waste.

Thermoforming and Bending Processes

Thermoforming is where heat comes in handy. You heat the acrylic until it's bendable, then mold it to your shape. Bending can be done with simple heat guns or more advanced tools. This process is used for creating curves or custom shapes. It’s perfect for unique displays or artistic installations.

Joining Acrylic: Adhesives and Welding

Joining acrylic pieces requires special techniques. You can use adhesives like solvent-based glues for a clear bond. They dissolve the acrylic surface slightly, which helps make a strong joint. For a more industrial approach, you might try plastic welding. This method uses heat to fuse pieces together. Both ensure durability and a neat finish.

Finishing Techniques: Polishing and Edging

Once shaped and joined, polishing and edging add the final touch. Polishing removes scratches and adds shine, using tools like buffing wheels. Sanding can smooth out edges and make them safe to touch. For a frosted look, consider sanding with fine grit paper. These finishing steps are crucial for visual appeal and safety.

Innovations in Acrylic Fabrication

Acrylic fabrication is always evolving. New methods improve efficiency and design. For instance, 3D printing is now used for custom shapes not possible before. Additionally, eco-friendly materials and practices are gaining ground. These innovations keep acrylic fabrication fresh and relevant, offering endless possibilities for creatives like you.

Applications of Acrylic in Dubai

Acrylic's popularity in Dubai isn't just a trend. It's here to stay because it meets varied needs across many industries.

Retail and Store Displays

Acrylic shines in retail. Stores use it for clear, eye-catching displays. Imagine walking through a Dubai mall. Those sleek shelves showcasing products? That's acrylic. It's lightweight yet strong, perfect for moving around during store updates. Stores love it because it shows products beautifully without stealing the spotlight.

Signage and Advertising

Want bold signs that last? Acrylic does that. You see it in a lot of Dubai's outdoor signs. It's weather-resistant and can be cut into custom shapes. Whether it's a brand's logo or an elaborate ad, acrylic makes sure it stands out. Plus, it works well with LED lights for those glowing signages you notice at night.

Architectural and Interior Design Elements

Architecture and design in Dubai thrive with acrylic. Designers use it for modern touches in homes and buildings. Think of clear partitions or funky furniture pieces. Acrylic is versatile, letting you create transparent, colored, or even frosted looks. It bridges functionality with style, fitting right into Dubai's sleek design aesthetic.

Automotive and Aerospace Uses

Acrylic isn’t just for looks; it’s tough too. The automotive and aerospace industries benefit from its strength and lightweight nature. For example, aircraft windows often use acrylic because it's clear and resists impact. Car manufacturers use it for light covers and interiors, balancing durability with design.

Specialty Applications in Art and Decoration

Artists and decorators love acrylic. It’s easy to shape and color to match creative visions. You see it in artistic installations across Dubai, like sculptures or decorative panels. It holds up outdoors too, making it ideal for public art pieces. Acrylic lets artists push boundaries without worrying about durability.

In each of these areas, acrylic proves why it’s a go-to material. From functional to artistic uses, it offers flexibility, strength, and style—all in one package.

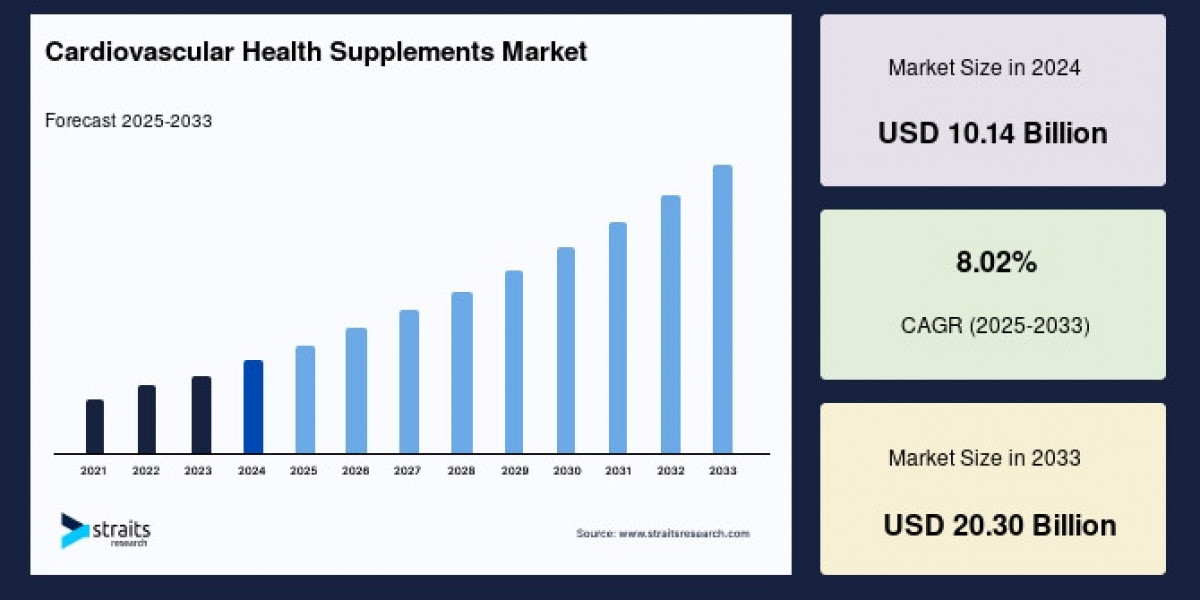

Industry Trends and Market Growth

Acrylic's role in Dubai's market is growing fast. More designers opt for it due to its versatility and sleek look. It's common in retail displays and architectural designs. According to industry watchers, the demand for acrylic is rising because it combines style with functionality. Acrylic's durability and ease of maintenance only add to its appeal. Experts predict continued growth, especially with eco-friendly trends catching on. Many companies now offer sustainable acrylic options to reduce environmental impact.

Dubai’s Role in the Global Market

Dubai is a major hub for acrylic fabrication globally. The city blends modern architecture with innovation, positioning it as a leader. Dubai-based companies serve local markets and export worldwide. They are often at the forefront of adopting new technologies, like LED-integrated acrylic. These innovations boost their competitiveness and influence in the global market. Dubai's strategic location also aids logistics and market reach, enhancing its role in international trade.

Regulations and Standards

Regulations ensure acrylic products meet quality and safety standards. Dubai follows strict guidelines for manufacturing and selling acrylic. These include rules on material strength and fire safety. Standards help protect consumers and maintain a level playing field for businesses. They also encourage companies to innovate sustainably. Keeping up with these regulations is crucial for any fabricator wanting to succeed in Dubai.

Future Prospects for the Industry

The future looks bright for acrylic fabrication in Dubai. Designers and builders continually seek versatile materials like acrylic. Emerging technologies promise more creative possibilities. There's also a growing focus on sustainability. Companies are investing in greener processes and materials. By embracing these trends, Dubai's acrylic industry is set to remain a vital part of its economy. Expect ongoing innovations and expanded uses in fields from architecture to retail.

Challenges and Solutions in Acrylic Fabrication

Diving into acrylic fabrication in Dubai? You're in for a treat! But like any craft, it isn't without its bumps. Let's look at some common challenges and ways to solve them in Dubai's unique setting.

Common Fabrication Challenges

Acrylic is an amazing material, but it can be tricky to work with. Many fabricators often face issues like material inconsistencies or thickness variations. These can cause mismatches in projects, especially when precision is crucial. If you're crafting a custom sign, even a small deviation can disrupt the final look.

To solve these issues, use quality-controlled materials. Ensure suppliers follow strict standards, so you get consistent thickness and clarity. Also, regularly calibrate your cutting equipment. This way, your cuts match the precise dimensions you need.

Environmental and Sustainability Concerns

Concerned about going green? You're not alone. Acrylic fabrication can produce waste, impacting the environment. In Dubai, sustainability is increasingly important, whether for regulations or corporate responsibility.

Look for eco-friendly acrylic options, like recycled materials. These help reduce waste and support eco-conscious projects. Some companies even offer recycling programs to reuse off-cuts or scrap materials. Choosing these options makes your projects more sustainable and appealing to eco-minded clients.

Technical Issues: Warping and Cracking

Warping and cracking can cause headaches in acrylic projects. These issues often happen when the material is not handled correctly, or when temperature changes occur too quickly during fabrication.

A simple tip? Keep your workshop climate-controlled to prevent abrupt temperature changes. When fabricating, heat acrylic evenly to avoid creating uneven stress points. Proper handling and careful temperature management will reduce warping and cracking significantly.

Cost-Effective Solutions

Working on a tight budget? Acrylic can be cost-efficient if approached wisely. Extruded acrylic is cheaper than cast, making it ideal for large-scale projects. It's great if you're planning extensive displays or partitions.

Plus, buy in bulk if possible. Bulk purchasing often lowers costs and provides material consistency. Also, use efficient techniques like laser cutting. It reduces material waste, saving money in the long run.

Innovative Problem-Solving Approaches

Thinking outside the box can uncover smart solutions. In Dubai, innovation thrives, so don't shy away from new tools. Modern methods like 3D printing allow for complex shapes not feasible before.

These technologies bring design ideas to life quickly. They also reduce trial and error, making your work more efficient. Embrace tech advancements and watch your fabrication projects shine with creativity and precision.

By understanding and addressing these challenges, you can enhance your acrylic projects in Dubai. Whether through smart planning or innovative techniques, solutions are within your reach.

Choosing the Right Acrylic Fabricator in Dubai

Choosing the right acrylic fabricator can feel like a daunting task. Don't worry; I'm here to help. Let's break it down into clear steps to ensure quality, capability, and great service.

Key Factors to Consider

First, look at experience and expertise. A fabricator with years of experience likely delivers better results. Ask about their past projects to gauge skills.

Next, evaluate their equipment. Modern tools like CNC machines and laser cutters ensure precise cuts and flawless finishes. Check if they offer comprehensive services, like design consultations or installation.

Finally, consider their reputation. Client reviews and testimonials can reveal a lot about their work quality and reliability.

Questions to Ask Potential Fabricators

Ask a few key questions to understand their process.

- "What materials do you specialize in?" ensures they handle acrylic well.

- "Can you provide a timeline for my project?" helps avoid delays.

- "Do you offer custom solutions?" ensures they can meet unique needs.

These questions can clarify if they're right for you.

Evaluating Quality and Service Metrics

Quality is crucial. Inspect their samples to check clarity, color consistency, and finish. A reputable fabricator won't mind providing these.

Great customer service is vital too. Are they responsive? Do they offer aftercare support? Good service means you won't be left hanging after project delivery.

Case Studies of Successful Projects

Case studies are treasure troves of info. They reveal what a fabricator can do. Look for projects similar to yours. See how they tackled challenges and check if the outcomes were successful. Plus, these examples can inspire your own project ideas.

Tips for Long-Term Partnerships

Building a long-term partnership brings many benefits. Consistency in quality and service is key. Regular updates and feedback loops foster better collaboration.

Consider creating a contract that outlines all terms clearly. This protects both parties and sets expectations from the start. Long-term partnerships often lead to more creative and efficient projects over time.

By taking these steps, you'll find the perfect acrylic fabricator in Dubai for your needs. Whether you're looking for sleek retail displays or unique architectural features, the right partner will make your vision shine.

Acrylic vs. Glass: Transparency and Durability

When deciding between acrylic and glass, look at transparency and durability. Acrylic is clear like glass but is much tougher. It resists shattering, unlike glass. This makes it safer for busy areas like malls or playgrounds. For example, if a shopping center display needs to be both clear and durable, acrylic is a go-to choice.

Acrylic vs. Polycarbonate: Cost and Strength

Acrylic and polycarbonate are both strong, but they differ in cost. Polycarbonate is more durable and impact-resistant. It's common in protective equipment like helmets. However, it's pricier. Acrylic is less costly and also resists weathering, making it better for budget projects that need moderate strength. If you’re setting up outdoor signs, acrylic might be enough while saving money.

Acrylic vs. Metal: Weight and Versatility

Acrylic is lightweight compared to metal. This makes it easy to handle and install. For example, acrylic is ideal for displays or fixtures needing frequent rearrangement. Metal, while strong and sturdy, can be harder to work with due to its weight. Also, acrylic can mimic the glossy finish of metal but is easier to mold into complex shapes, enhancing design versatility.

Comparative Case Studies

Consider real-life comparisons. For instance, in a project for an art gallery, acrylic was chosen over glass for sculpture cases. It provided a clear, unbreakable barrier, keeping artworks safe while allowing full visibility. Meanwhile, for a safety barrier in a sports arena, polycarbonate was preferred due to its superior impact resistance.

Choosing the Right Material for Your Needs

Choosing the right material depends on your specific needs. Sparkling clarity? Go acrylic. Need something that won’t crack under pressure? Polycarbonate’s your pick. Want something robust but easy to move? Acrylic is versatile and light. Always weigh the pros against any cost or strength needs your project has.

Let's wrap things up by spotlighting the bright future of acrylic fabrication in Dubai. From its crucial role in iconic projects like The Dubai Frame to its dominance in retail and interior displays, acrylic is reshaping the city's design landscape. With its benefits—versatility, durability, and eco-friendly options—acrylic satisfies both aesthetic and practical needs. Leading acrylic companies in Dubai are driving this evolution by offering innovative fabrication techniques and customized solutions for a wide range of industries.

As you plan your next project, remember the importance of a reliable fabricator. Seek those with strong reputations who offer innovative solutions and sustainable practices. Dive into the possibilities and choose acrylic to bring your most ambitious design dreams to life.