In today’s competitive industrial landscape, achieving unmatched accuracy and surface quality is no longer just a goal—it’s a necessity. Among the many advancements powering modern manufacturing, Diamond machine manufacturing stands out as a transformative solution for industries that rely on high-precision cutting and finishing.

Whether you’re crafting intricate jewelry dies, engineering automotive parts, or producing specialized components for electronics, diamond machining delivers exceptional consistency, speed, and finesse that traditional methods simply can’t match.

What is Diamond Machine Manufacturing?

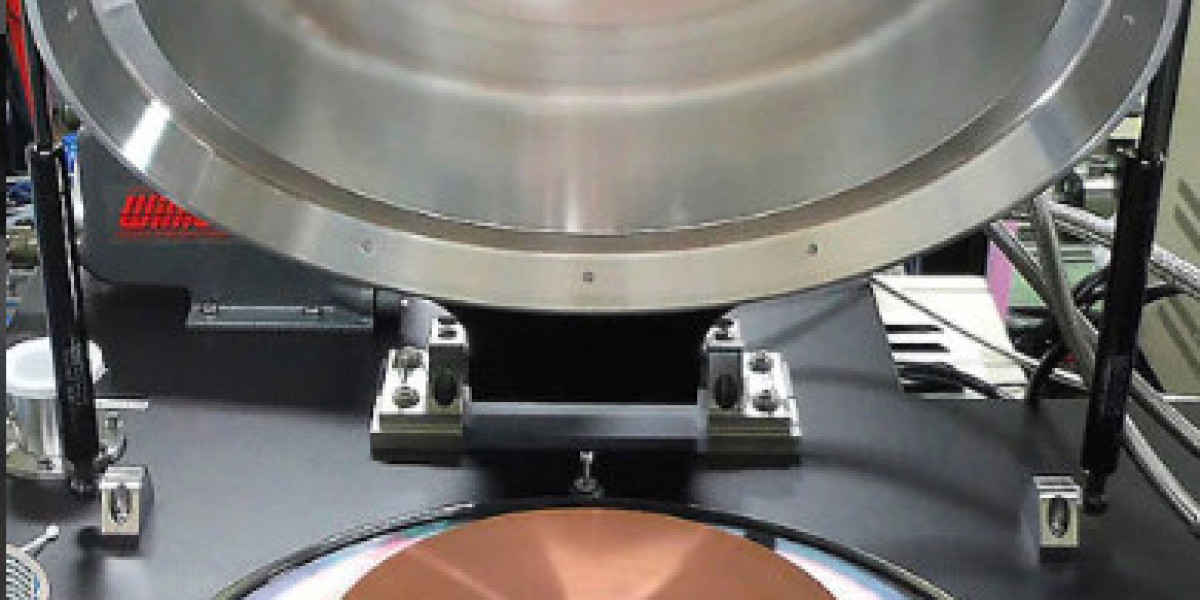

At its core, Diamond machine manufacturing involves the use of machines equipped with diamond-tipped tools to perform high-precision turning, milling, and cutting operations. Diamond, being the hardest known material, allows manufacturers to achieve ultra-smooth finishes and extremely tight tolerances on a wide range of hard and delicate materials.

From optical lenses and semiconductors to custom mold cavities, the reach of diamond machining extends across countless high-tech applications.

Why Industries Choose Diamond Machine Manufacturing

💎 Ultra-Precise Surface Finishes

The primary advantage of using diamond tooling lies in its ability to produce surfaces with nanometer-level smoothness. This is crucial in fields like optics and electronics, where even microscopic imperfections can lead to product failures.

🚀 Faster, Cleaner Cuts

Diamond tools maintain their sharpness much longer than conventional carbide or steel tools. This means fewer tool changes, reduced downtime, and consistently cleaner cuts throughout long production runs.

🛠️ Versatility Across Materials

Whether machining hardened steel, carbide, ceramics, or delicate non-ferrous alloys, diamond-tipped machines handle them with ease. This adaptability reduces the need for multiple machines or tool setups, simplifying your workshop.

Key Applications of Diamond Machining

Diamond machine manufacturing is a backbone technology across many industries, including:

Jewelry & Die Making: Crafting intricate patterns and textures in metal dies for jewelry production.

Automotive: Producing components that require extremely low friction surfaces and precise geometries.

Semiconductor & Electronics: Achieving flawless finishes on delicate silicon wafers and circuit substrates.

Aerospace: Ensuring lightweight yet high-strength components meet the highest standards for surface smoothness.

Why Trust keytexmachines?

Investing in advanced technology requires a reliable partner, and keytexmachines is known for delivering machines that combine innovative engineering with robust performance.

Their diamond machining solutions stand out for:

Rigid Construction: Minimizes vibration for consistently precise results.

Advanced CNC Systems: Makes programming complex geometries intuitive and reduces operator errors.

Durability: Engineered for long tool life and high-volume operations without frequent maintenance interruptions.

Beyond the machines themselves, their team provides expert support to help you integrate the right solutions into your production line, ensuring maximum return on investment.

Moving Towards Smart Manufacturing

Modern production isn’t just about machining—it's about smart integration. Today’s diamond machining systems often come equipped with:

Real-time process monitoring: Ensures quality is maintained throughout the operation.

Automated tool wear detection: Alerts operators before minor issues become costly downtime.

Data analytics: Helps optimize machining strategies, leading to lower scrap rates and higher yields.

By combining the unmatched cutting ability of diamond tooling with IoT-enabled controls, manufacturers can streamline workflows, improve part quality, and enhance overall productivity.

Future-Proof Your Manufacturing with Diamond Machining

As industries continue to push for higher standards and tighter tolerances, the demand for advanced machining solutions only grows. Embracing Diamond machine manufacturing ensures your business stays ahead, capable of delivering intricate components that meet rigorous quality requirements.

Whether you’re scaling up for larger production volumes or seeking to produce innovative new parts, diamond machining equips you with the capability to turn ambitious designs into reliable, high-performance products.

Conclusion

Precision is more than a specification—it's a reputation. With the power of Diamond machine manufacturing, you’re not just achieving exceptional finishes and dimensions; you’re building trust with every client you serve.

With partners like keytexmachines, you gain more than just advanced machinery. You secure a long-term ally dedicated to pushing your production capabilities forward. Ready to elevate your workshop’s standards? The future of high-precision manufacturing starts here.