The Atomic Layer Deposition (ALD) market is gaining remarkable traction across multiple industries owing to its precise material deposition capabilities, especially in the fields of semiconductors, electronics, and nanotechnology. As technology continues to scale down in size, the demand for atomic-level precision in material deposition techniques has become crucial. ALD, known for producing ultra-thin films with controlled thickness and high uniformity, is thus increasingly becoming indispensable in modern manufacturing processes.

Atomic Layer Deposition is a vapor-phase technique used to deposit thin films onto substrates in a controlled, layer-by-layer fashion. It is distinguished from other chemical vapor deposition (CVD) processes by its ability to coat substrates with atomic-scale thickness control, superior conformality, and high repeatability. The ALD market is witnessing expansion due to its growing application in semiconductors, data storage, solar panels, medical devices, and protective coatings.

The global ALD market is expected to exhibit strong growth over the coming decade, driven by the miniaturization of electronic components, the advancement of 3D NAND and FinFET technologies, and the rising demand for energy-efficient devices. Additionally, ongoing research in flexible electronics and nanostructured materials is opening new avenues for ALD applications.

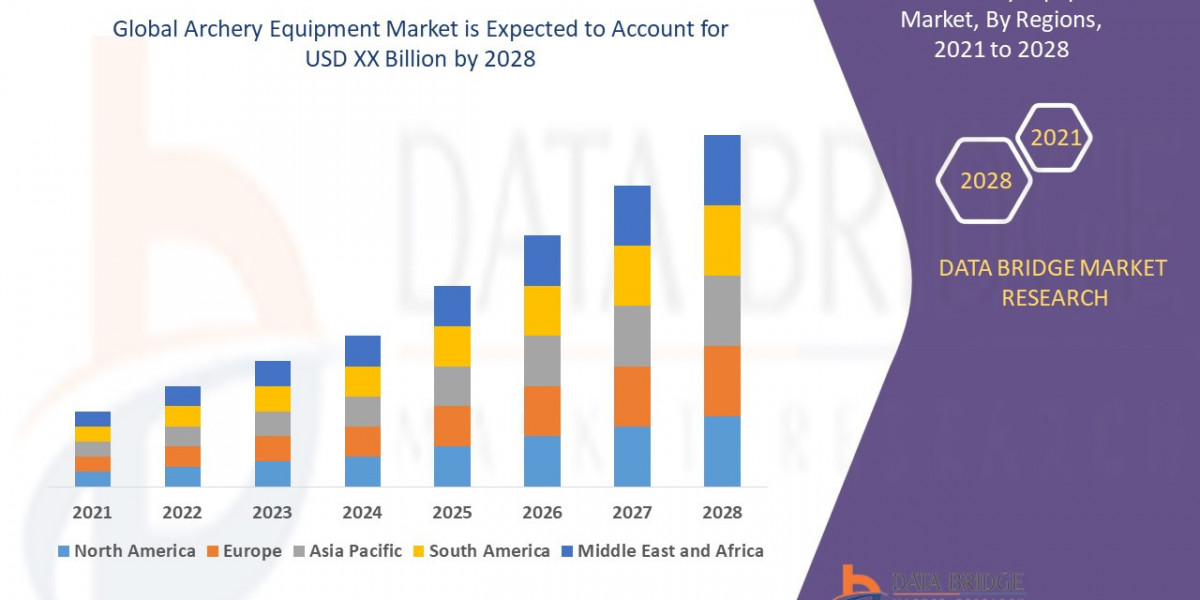

Atomic Layer Deposition (ALD) Market exhibiting a compound annual growth rate (CAGR) of 13.9% during the forecast period (2022 - 2030).

Key Market Drivers

- Rising Demand in Semiconductor Manufacturing

The primary driver of the ALD market is its critical role in semiconductor device fabrication. As transistors shrink in size to meet Moore’s Law, traditional deposition methods are proving inadequate. ALD provides the needed precision and film quality for modern chips, especially in high-k/metal gate structures, capacitors, and advanced node transistors. - Emergence of 3D Structures in Electronics

The rise of 3D architectures in NAND flash memory and FinFET transistors has propelled the need for conformal coating technologies. ALD excels in depositing uniform films over complex 3D surfaces, making it a preferred choice for next-generation electronic components. - Growth in Photovoltaics and Energy Storage

ALD is gaining ground in the solar energy sector for enhancing cell efficiency and lifetime. In lithium-ion batteries, it is used for coating electrode materials to improve stability and performance. As renewable energy adoption grows, ALD is expected to play a pivotal role in enabling efficient energy devices. - Expanding Use in Medical and Optical Devices

The ALD market is also benefiting from its application in the medical sector, particularly in biocompatible coatings, drug delivery systems, and implantable devices. Similarly, it is used in optical coatings to improve reflectivity, anti-reflection, and durability. - Advances in Research and Development

Continuous R&D activities aimed at developing novel precursor materials, enhancing deposition rates, and scaling ALD for industrial applications are fostering market growth. Collaborations between academia and industry are also spurring innovation in this field.

Key players in the Atomic Layer Deposition (ALD) Market include:

ALD NanoSolutions, Inc (US), Applied Materials, Inc (US), ASM International NV (The Netherlands), ALD Vacuum Technologies GmbH (Germany), Jiangsu Leadmicro Guide Nano Equipment Technology Co., Ltd (China), CVD Equipment Corporation (US), Tokyo Electron Limited (Japan), Denton Vacuum (US), Kurt J. Lesker Company (UK), and Veeco Instruments (US).

Market Challenges

Despite its numerous advantages, the ALD market faces certain challenges:

- High Cost of Equipment and Process: ALD systems and precursor materials are expensive, limiting adoption in price-sensitive sectors.

- Slow Deposition Rates: Compared to other deposition methods like sputtering or CVD, ALD has slower deposition rates, which can hinder throughput for large-scale production.

- Complexity of Process Integration: Integrating ALD into existing manufacturing workflows can be technically complex, especially in legacy systems.

For More Information Request for Sample PDF

Emerging Trends

- Spatial ALD (SALD)

An advanced form of ALD, SALD offers higher deposition rates, making it more viable for industrial-scale applications such as photovoltaics and flexible electronics. - Roll-to-Roll ALD

This approach enables the continuous coating of flexible substrates, opening doors to low-cost, large-area applications in flexible displays, smart packaging, and sensors. - In-situ Process Monitoring

Development of real-time diagnostics and monitoring systems is improving process control, enabling tighter specifications for industrial users. - Green Precursors and Sustainable Processes

Growing focus on reducing the environmental impact of deposition processes is leading to the development of safer, less toxic precursors and energy-efficient equipment. - Integration with Atomic Precision Manufacturing

ALD is becoming a foundational component in atomic-scale manufacturing workflows, particularly for quantum computing, advanced lithography, and nanoelectronics.

Contact Us:

Market Researcnh Future (Part of WantStats Research and Media Pvt. Ltd.)

Contact Number. +91 2269738890

Email: sales@marketresearchfuture.com