When it comes to construction work, especially projects that involve driving or extracting piles, a vibrating hammer can be one of the most valuable tools. Selecting the right vibrating hammer for your project is important because it affects the efficiency, cost, and quality of the work. If you choose the wrong type or size, you may face delays, higher expenses, or even damage to your materials. This guide will help you understand what a vibrating hammer is, how it works, the types available, and how to select the best one for your needs.

What is a Vibrating Hammer?

A vibrating hammer is a machine used in construction to drive piles into the ground or remove them. It works by creating vibrations that reduce the friction between the pile and the soil, allowing the pile to go deeper with less resistance. This method is faster and often less noisy than using an impact hammer, making it suitable for many modern construction projects.

The vibrating hammer is usually attached to a crane or excavator, and it can be used for steel sheet piles, tubular piles, H-beams, or other materials depending on the design.

How Does a Vibrating Hammer Work?

The vibrating hammer uses an eccentric weight system inside its housing. When the machine is turned on, the weights spin in opposite directions, creating vibrations. These vibrations travel into the pile, loosening the surrounding soil particles. With reduced friction, the pile moves more easily into the ground when downward force is applied.

This method works well for sandy, loose, or granular soils but may not be suitable for rocky or very hard clay surfaces unless special equipment is used.

Why Choosing the Right Vibrating Hammer Matters

Not all projects are the same. The type of soil, the kind of pile, the required depth, and the available equipment all affect which vibrating hammer will work best. Using the wrong hammer can:

Increase fuel and operation costs

Cause damage to piles or equipment

Slow down the project

Lead to unsafe working conditions

This is why it is important to choose carefully.

Key Factors to Consider When Choosing a Vibrating Hammer

1. Type of Piles You Will Use

Different piles require different power levels and clamp sizes. For example:

Steel sheet piles often need less force than large-diameter tubular piles.

Concrete piles may require a heavier vibrating hammer with more driving force.

Make sure the hammer you select is compatible with your pile type.

2. Soil Conditions

The efficiency of a vibrating hammer depends greatly on soil type.

Loose sandy soils are ideal for vibrating hammers.

Dense clay or rocky ground may need additional driving force or different pile installation methods.

It is best to check the soil report for your site before making a choice.

3. Driving Depth

If your project requires deep driving, you will need a vibrating hammer with more power. Shallow projects can be completed with smaller, lighter machines. Choosing a hammer with too little power for a deep project can cause delays and extra costs.

4. Machine Compatibility

A vibrating hammer is usually attached to a crane or an excavator. The hammer must match the lifting and hydraulic capacity of your machine. If it is too heavy or requires more hydraulic power than your equipment can supply, it will not function properly.

5. Frequency and Amplitude

The frequency refers to how fast the hammer vibrates, while amplitude refers to how much movement occurs during each vibration.

High frequency is better for sensitive urban areas as it reduces noise and disturbance.

Lower frequency with higher amplitude is often better for heavy-duty jobs.

6. Weight of the Vibrating Hammer

Heavier hammers can drive piles faster but require stronger lifting equipment. Lighter hammers are easier to handle but may be slower for large piles.

7. Quality and Reliability

A vibrating hammer is a big investment. Choosing a well-made machine reduces the risk of breakdowns. Look for a hammer with a strong build, quality components, and a design suited for long-term use.

8. Safety Features

The right vibrating hammer should have safety features such as secure clamps, emergency stop controls, and stability during operation. A safe hammer reduces the risk of accidents.

Benefits of Using the Right Vibrating Hammer

When you choose the right vibrating hammer for your project, you get:

Faster pile installation or extraction

Lower fuel and labor costs

Less noise compared to impact methods

Reduced wear and tear on piles

Safer working conditions

Mistakes to Avoid When Selecting a Vibrating Hammer

Ignoring soil conditions – Some hammers may not work well in certain soils.

Choosing only based on price – The cheapest option may not be powerful enough.

Not checking machine compatibility – If your excavator or crane cannot handle the hammer, it will not work.

Overlooking maintenance needs – A hammer that is hard to maintain can cause downtime.

Maintaining Your Vibrating Hammer

Once you choose the right vibrating hammer, proper care is important.

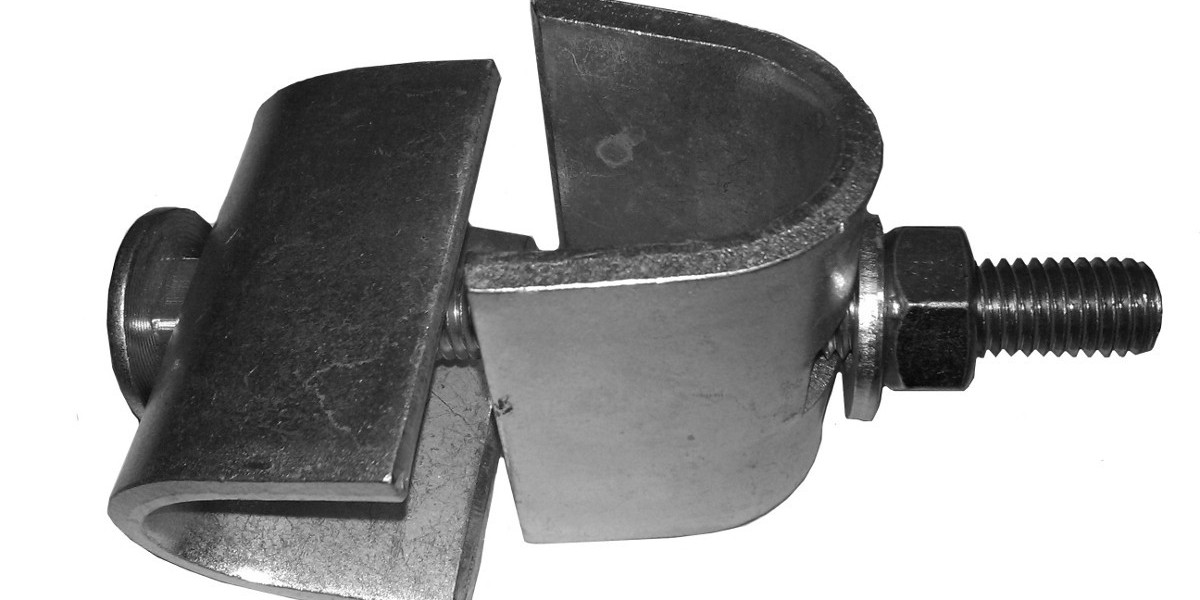

Inspect the clamps regularly to make sure they grip securely.

Check hydraulic lines for leaks or damage.

Keep the machine clean to prevent dirt from damaging moving parts.

Follow the manufacturer’s service schedule.

Regular maintenance ensures your vibrating hammer lasts longer and performs well throughout your project.

Conclusion

Choosing the right vibrating hammer for your project is not just about buying or renting any machine. It requires understanding your piles, soil conditions, equipment, and project goals. By considering the factors discussed above, you can select a vibrating hammer that delivers speed, safety, and efficiency. The right choice will help your project finish on time, within budget, and with high-quality results.