The global technical ceramics market is experiencing remarkable growth, fueled by their exceptional properties and expanding applications across diverse industries. Technical ceramics, also known as advanced ceramics, are engineered materials designed to withstand extreme conditions, including high temperatures, mechanical stress, and corrosive environments. They exhibit superior characteristics such as high hardness, thermal and chemical stability, wear resistance, and excellent electrical insulation, making them indispensable in modern industrial applications.

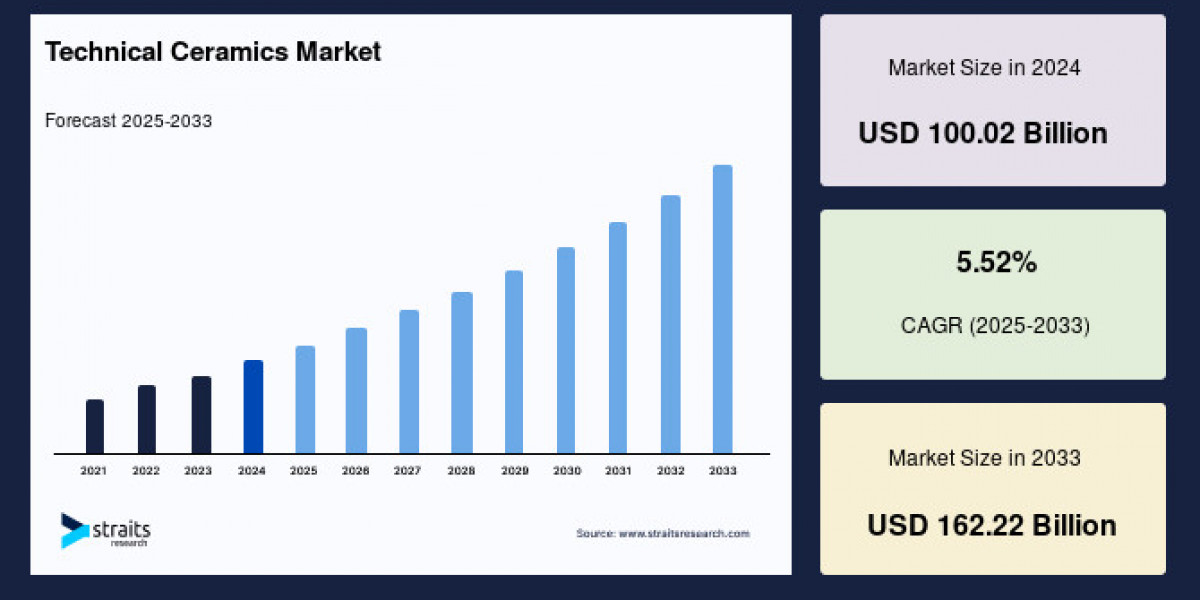

The global technical ceramics market size was valued at USD 100.02 billion in 2024 and is projected to grow from USD 105.54 billion in 2025 to reach USD 162.22 billion by 2033, growing at a CAGR of 5.52% during the forecast period (2025–2033).

Market Overview

Technical ceramics are used in a wide range of industries, including automotive, aerospace, electronics, energy, healthcare, and defense. Their unique properties enable them to perform in conditions where conventional materials, such as metals and plastics, may fail. For instance, ceramic components in aerospace engines can withstand extreme temperatures while reducing weight, and in electronics, ceramic substrates improve device performance through efficient thermal management.

The market is further segmented based on material type, application, and region, allowing manufacturers to cater to industry-specific requirements while driving innovation in product development.

Key Drivers of Market Growth

1. Expanding Industrial Applications

Technical ceramics are increasingly adopted in automotive, aerospace, and industrial machinery due to their high durability, corrosion resistance, and ability to withstand extreme operating conditions. In the automotive sector, ceramics are used in engine components, sensors, brake systems, and catalytic converters to enhance performance and fuel efficiency. The aerospace industry employs ceramics in turbine blades, heat shields, and structural components to reduce weight and increase thermal efficiency. Industrial machinery benefits from ceramic coatings and components that extend equipment life and reduce maintenance costs.

2. Advancements in Electronics and Semiconductor Technology

The electronics and semiconductor sectors are major growth drivers for technical ceramics. Materials like alumina, zirconia, and silicon carbide are used in substrates, insulators, and microelectronic devices due to their high thermal conductivity, electrical insulation, and dimensional stability. The proliferation of miniaturized devices, IoT-enabled electronics, and high-performance computing equipment is fueling demand for advanced ceramic materials.

3. Growth in Renewable Energy and Sustainable Technologies

The transition to renewable energy has created new opportunities for technical ceramics. These materials are integral to the manufacture of solar panels, wind turbines, and energy storage systems due to their resistance to heat, corrosion, and environmental stress. For example, ceramics in photovoltaic modules improve efficiency and longevity, while ceramic coatings in wind turbine components enhance durability under harsh conditions.

4. Healthcare and Medical Applications

Technical ceramics are widely used in medical devices, including orthopedic implants, dental prosthetics, and surgical instruments, due to their biocompatibility and wear resistance. Advanced ceramics ensure longevity and reduce the risk of infections or complications, making them essential in the healthcare industry.

5. Research and Development Initiatives

Ongoing R&D is enabling the development of next-generation ceramic materials with tailored properties. Innovations in nanostructured ceramics, composite materials, and additive manufacturing are expanding their applications in emerging industries such as electric vehicles (EVs), aerospace propulsion, and high-performance electronics.

Regional Insights

Asia-Pacific dominates the global technical ceramics market, driven by rapid industrialization, growing automotive and electronics sectors, and the presence of major manufacturing hubs in China, Japan, and South Korea. The region benefits from supportive government initiatives promoting advanced materials and technological development.

North America holds a significant market share due to advanced industrial infrastructure, high adoption of innovative technologies, and strong R&D capabilities. The region’s focus on aerospace, defense, and semiconductor industries sustains demand for specialized ceramic materials.

Europe is witnessing steady growth, supported by automotive innovation, renewable energy adoption, and healthcare advancements. Regulatory frameworks emphasizing sustainability and energy efficiency further encourage the use of technical ceramics.

Market Segmentation

By Material Type:

Alumina (Al₂O₃)

Zirconia (ZrO₂)

Silicon Nitride (Si₃N₄)

Silicon Carbide (SiC)

Others (Titanium Diboride, Boron Nitride, etc.)

By Application:

Automotive Components

Aerospace and Defense

Electronics and Semiconductor

Energy (Renewable & Conventional)

Healthcare and Medical Devices

Industrial Machinery

Others

By Region:

Asia-Pacific

North America

Europe

Latin America

Middle East & Africa

Competitive Landscape

The global technical ceramics market is highly competitive, with major players investing heavily in R&D and strategic partnerships to strengthen their market presence. Key players include:

CoorsTek Inc.

Kyocera Corporation

CeramTec GmbH

Morgan Advanced Materials

NGK Spark Plug Co., Ltd.

3M Company

Saint-Gobain Ceramic Materials

These companies focus on innovation, expanding production capacities, and developing advanced materials tailored for specific industrial applications. Collaborations with automotive, aerospace, and electronics manufacturers are also common, facilitating the adoption of cutting-edge ceramic technologies.

Challenges

Despite strong growth prospects, the market faces challenges such as high production costs, complex manufacturing processes, and raw material availability. Additionally, competition from alternative materials like metals and polymers in certain applications may limit growth. Addressing these challenges through cost-effective production techniques and continuous innovation is crucial for market expansion.

Opportunities

Electric Vehicles (EVs): The rise of EVs is driving demand for lightweight, high-performance ceramic components in batteries, motors, and thermal management systems.

Additive Manufacturing: 3D printing of technical ceramics is enabling the creation of complex geometries and customized components, opening new applications in aerospace and healthcare.

Sustainability Initiatives: Environmentally friendly ceramic production methods and eco-conscious applications in renewable energy systems present growth opportunities.

Conclusion

The technical ceramics market is poised for sustained growth, driven by technological innovation, expanding industrial applications, and increasing demand for high-performance materials. With advancements in electronics, automotive, aerospace, and renewable energy sectors, technical ceramics are set to play a pivotal role in shaping the future of industrial and technological development. Continuous R&D, strategic collaborations, and a focus on sustainability will further strengthen the market and open new avenues for growth.