The global meat mixer market is experiencing substantial growth due to rising demand for processed meat products, increasing meat consumption worldwide, and advancements in meat processing technologies.

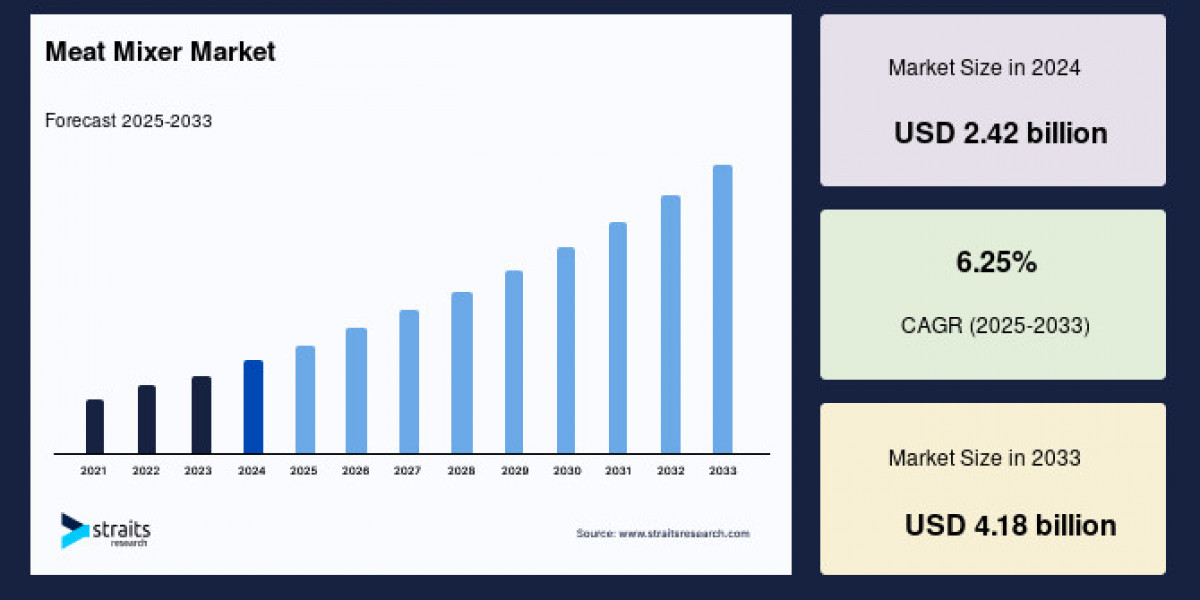

The global meat mixer market size was valued at USD 2.42 billion in 2024. It is estimated to reach from USD 2.57 billion in 2025 to USD 4.18 billion by 2033, growing at a CAGR of 6.25% during the forecast period (2025–2033). The market growth is driven by factors such as changing consumer preferences, urbanization, and the demand for high-quality, consistent meat products in both industrial and commercial settings.

Market Overview

Meat mixers are specialized machines used in the food processing industry to blend meat with other ingredients, ensuring uniform consistency, texture, and flavor. They are widely utilized in meat processing plants, butcher shops, restaurants, and ready-to-eat food production units. Meat mixers improve operational efficiency, reduce manual labor, and enhance product quality.

With increasing urban populations and changing lifestyles, consumers are leaning toward processed and ready-to-cook meat products. This trend has created significant opportunities for manufacturers of meat mixers to expand their product portfolios and offer advanced, automated solutions that meet industrial and commercial needs.

Key Market Drivers

Increasing Global Meat Consumption

Rising population and changing dietary habits have led to higher demand for meat products worldwide. Meat mixers are essential for maintaining consistent quality in large-scale meat processing operations, making them a critical investment for processors.Technological Advancements in Equipment

Innovations such as automated mixing systems, vacuum mixers, spiral mixers, and energy-efficient electric meat mixers enhance productivity, reduce processing time, and ensure uniform mixing. These technological improvements have expanded the capabilities of meat mixers, enabling their use in both small and large-scale operations.Rising Demand for Processed and Ready-to-Eat Meat Products

Busy lifestyles and urbanization are increasing the demand for processed meat products like sausages, patties, and pre-marinated meats. Meat mixers are integral to producing these items efficiently while maintaining high-quality standards.Food Safety and Quality Regulations

The need to comply with stringent food safety standards encourages meat processors to adopt modern, hygienic meat mixing equipment. Advanced mixers help maintain hygiene and prevent contamination during processing.

Market Segmentation

By Type:

Paddle Mixers: Provide gentle mixing suitable for delicate meat products.

Spiral Mixers: Designed for high-volume meat processing with uniform mixing efficiency.

Vacuum Mixers: Remove air during mixing, extending shelf life and improving product texture.

Others: Includes specialized mixers for unique applications in meat processing.

By Capacity:

Low-Capacity Mixers: Ideal for small butcher shops and restaurants.

Medium-Capacity Mixers: Used in medium-sized processing plants.

High-Capacity Mixers: Suited for large industrial meat processing operations.

By Power Type:

Electric Meat Mixers: Most widely used for consistent performance and ease of operation.

Hydraulic Meat Mixers: Provide higher torque for heavy-duty applications.

Manual/Mechanical Meat Mixers: Still used in smaller operations where electricity is limited.

By End-User:

Meat Processing Plants: Largest segment due to high demand for consistent quality and efficiency.

Butcher Shops: Small and medium-sized shops adopt compact mixers for daily operations.

Restaurants & Catering Services: Increasing demand for processed meat dishes drives growth in this segment.

Others: Includes ready-to-eat food producers and specialty meat product manufacturers.

By Region:

North America: Holds a significant market share due to high meat consumption, advanced processing technologies, and strict food safety regulations.

Asia-Pacific: Expected to witness the fastest growth, driven by rising urbanization, disposable income, and increasing meat consumption.

Europe: Maintains steady growth due to mature markets, strong regulatory frameworks, and a preference for processed meat products.

Latin America & Middle East & Africa: Emerging markets show promising growth with expanding food processing industries.

Market Challenges

High Initial Investment

Advanced meat mixers require substantial capital investment, which can be a barrier for small and medium-sized enterprises.Regulatory Compliance

Adhering to stringent food safety, hygiene, and quality standards increases operational costs and requires regular equipment maintenance.Maintenance and Operational Costs

High-capacity and automated mixers can involve significant maintenance expenses, which may affect profitability for smaller operators.

Opportunities

Adoption of Automated and Smart Mixers

Growing interest in Industry 4.0 and automation presents opportunities for manufacturers to introduce smart mixers with enhanced monitoring, control, and energy efficiency features.Expansion in Emerging Markets

Increasing urban populations, higher disposable incomes, and growing awareness of processed food products in Asia-Pacific, Latin America, and Africa provide significant growth potential.Innovation in Functional Mixers

Development of mixers that can incorporate marinades, spices, and additives during processing can attract food manufacturers seeking differentiated products.Sustainability Trends

Energy-efficient mixers and equipment designed to minimize waste align with global sustainability trends, offering competitive advantages.

Future Outlook

The global meat mixer market is expected to grow steadily over the next decade, supported by the increasing demand for processed meat products, technological advancements, and expanding food service sectors. Companies that invest in automation, smart features, energy efficiency, and compliance with food safety standards will gain a competitive edge.

As consumer preferences shift toward convenience foods and industrial meat processing scales up to meet global demand, the adoption of advanced meat mixers is likely to rise, making this sector a lucrative space for manufacturers and investors alike.